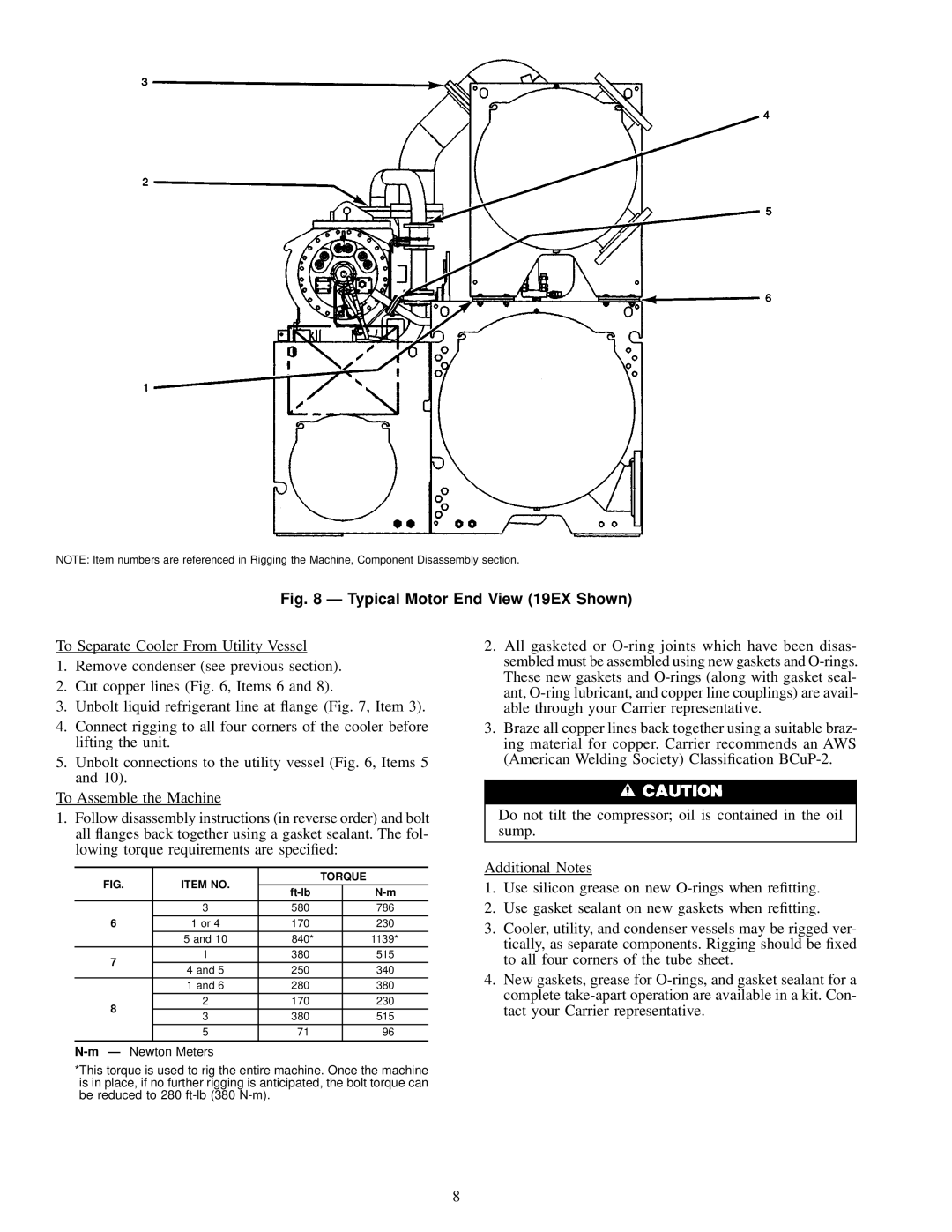

NOTE: Item numbers are referenced in Rigging the Machine, Component Disassembly section.

Fig. 8 Ð Typical Motor End View (19EX Shown)

To Separate Cooler From Utility Vessel

1.Remove condenser (see previous section).

2.Cut copper lines (Fig. 6, Items 6 and 8).

3.Unbolt liquid refrigerant line at ¯ange (Fig. 7, Item 3).

4.Connect rigging to all four corners of the cooler before lifting the unit.

5.Unbolt connections to the utility vessel (Fig. 6, Items 5 and 10).

To Assemble the Machine

1.Follow disassembly instructions (in reverse order) and bolt all ¯anges back together using a gasket sealant. The fol- lowing torque requirements are speci®ed:

2.All gasketed or

3.Braze all copper lines back together using a suitable braz- ing material for copper. Carrier recommends an AWS (American Welding Society) Classi®cation

Do not tilt the compressor; oil is contained in the oil sump.

FIG. | ITEM NO. |

| TORQUE | |

|

| |||

|

|

| ||

| 3 | 580 |

| 786 |

6 | 1 or 4 | 170 |

| 230 |

| 5 and 10 | 840* |

| 1139* |

7 | 1 | 380 |

| 515 |

4 and 5 | 250 |

| 340 | |

|

| |||

| 1 and 6 | 280 |

| 380 |

8 | 2 | 170 |

| 230 |

3 | 380 |

| 515 | |

|

| |||

| 5 | 71 |

| 96 |

|

|

|

|

|

Additional Notes

1.Use silicon grease on new

2.Use gasket sealant on new gaskets when re®tting.

3.Cooler, utility, and condenser vessels may be rigged ver- tically, as separate components. Rigging should be ®xed to all four corners of the tube sheet.

4.New gaskets, grease for

*This torque is used to rig the entire machine. Once the machine is in place, if no further rigging is anticipated, the bolt torque can be reduced to 280

8