COMPONENT DISASSEMBLY

To Separate Compressor from the Machine

1.Make sure to check that the machine is at atmospheric pressure before disassembly.

2.Since the center of gravity is high on 17EX machines, the motor MUST be removed before rigging the machine.

3.Suction elbow should be rigged separately (Fig. 6, Item 2). Place slings around the elbow and attach to the hoist. Remove bolting at ¯anges, (Fig. 6, Items 1 and 3). Detach the elbow.

4.Unbolt discharge ¯ange to the condenser at ¯ange (Fig. 8, Item 3). Cut copper lines (Fig. 6, Items 7, 8, and 9).

5.Disconnect and detach the economizer vent line (Fig. 8, Item 4). Unbolt the line at ¯ange (Fig. 8, Item 2).

6.On 19EX machines, disconnect the motor cooling drain line at ¯ange (Fig. 8, Item 5).

7.Disconnect wiring to the control center and power panel.

8.Connect rigging to the compressor.

9.Unbolt compressor from the utility vessel (Fig. 7, Items 2, 4, and 5).

10.Hoist the compressor off of the unit.

11.If the compressor is to be transported or set down, the base should be bolted to sections of 4 in. x 6 in. lumber.

To Separate Condenser from the Machine

1.Unbolt ¯ange (Fig. 6, Item 3).

2.Unbolt ¯ange (Fig. 6, Item 4).

3.Cut copper pipe (Fig. 6, Item 7).

4.Unbolt hot ¯ange (Fig. 7, Item 1).

5.Connect rigging to all corners of the condenser.

6.Unbolt condenser feet (Fig. 8, Items 1 and 6).

|

|

|

|

| LEGEND |

|

|

|

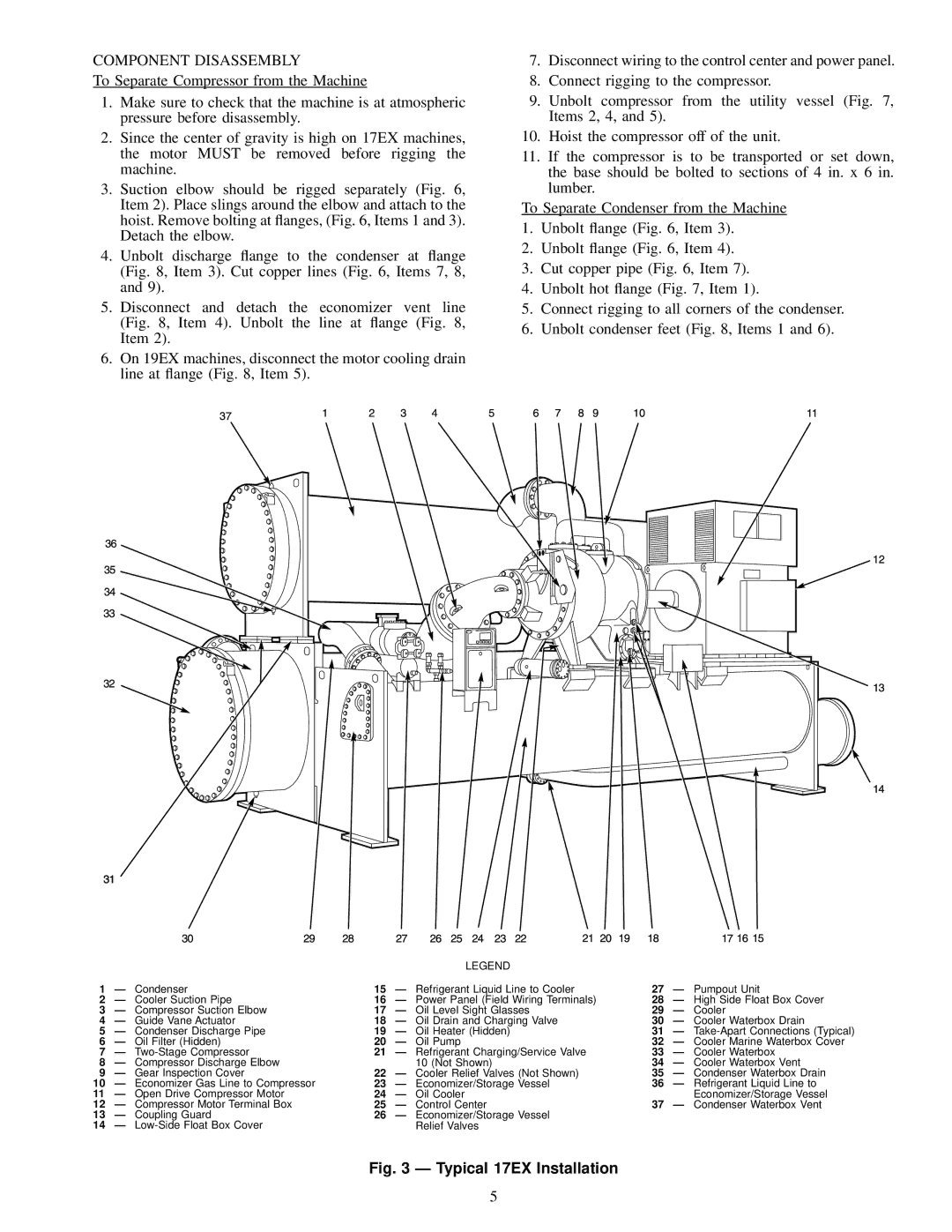

1 | Ð | Condenser | 15 | Ð | Refrigerant Liquid Line to Cooler | 27 | Ð | Pumpout Unit |

2 | Ð | Cooler Suction Pipe | 16 | Ð | Power Panel (Field Wiring Terminals) | 28 | Ð | High Side Float Box Cover |

3 | Ð | Compressor Suction Elbow | 17 | Ð | Oil Level Sight Glasses | 29 | Ð | Cooler |

4 | Ð | Guide Vane Actuator | 18 | Ð | Oil Drain and Charging Valve | 30 | Ð | Cooler Waterbox Drain |

5 | Ð | Condenser Discharge Pipe | 19 | Ð | Oil Heater (Hidden) | 31 | Ð | |

6 | Ð | Oil Filter (Hidden) | 20 | Ð | Oil Pump | 32 | Ð | Cooler Marine Waterbox Cover |

7 | Ð | 21 | Ð | Refrigerant Charging/Service Valve | 33 | Ð | Cooler Waterbox | |

8 | Ð | Compressor Discharge Elbow |

|

| 10 (Not Shown) | 34 | Ð | Cooler Waterbox Vent |

9 | Ð | Gear Inspection Cover | 22 | Ð | Cooler Relief Valves (Not Shown) | 35 | Ð | Condenser Waterbox Drain |

10 | Ð Economizer Gas Line to Compressor | 23 | Ð | Economizer/Storage Vessel | 36 | Ð | Refrigerant Liquid Line to | |

11 | Ð Open Drive Compressor Motor | 24 | Ð | Oil Cooler |

|

| Economizer/Storage Vessel | |

12 | Ð Compressor Motor Terminal Box | 25 | Ð | Control Center | 37 | Ð | Condenser Waterbox Vent | |

13 | Ð | Coupling Guard | 26 | Ð | Economizer/Storage Vessel |

|

|

|

14 | Ð |

|

| Relief Valves |

|

|

| |

Fig. 3 Ð Typical 17EX Installation

5