Install Field Insulation

Protect insulation from weld heat damage and weld splat- ter. Cover with wet canvas cover during water piping installation.

When installing insulation at the job site, insulate the fol- lowing components (see Fig. 24 and Table 15):

·compressor motor

·cooler shell

·cooler tube sheets

·suction piping

·motor cooling drain

·oil cooler refrigerant side tubing

·utility vessel (low side)

Additional insulation of condenser and compressor com- ponents and lines may be necessary to prevent condensation on these components.

NOTE: Carrier does not provide waterbox insulation. Insu- lation of the waterbox covers must be ®eld supplied at the jobsite. When insulating the waterbox covers, allow enough room for removal of the waterbox covers during servicing.

FACTORY INSULATION (OPTIONAL) Ð Optional factory insulation is available for the evaporator shell and tube sheets, suction pipe, compressor motors, and refriger- ant drain line(s). Insulation applied at the factory is 3¤4 in. (19.0 mm) thick and has a thermal conductivity K value of

0.28 | Btu | in. | (0.0404 | W | °C). Insulation conforms |

hr ft2 | °F | m |

with UL Standard 94, Classi®cation 94 HBF.

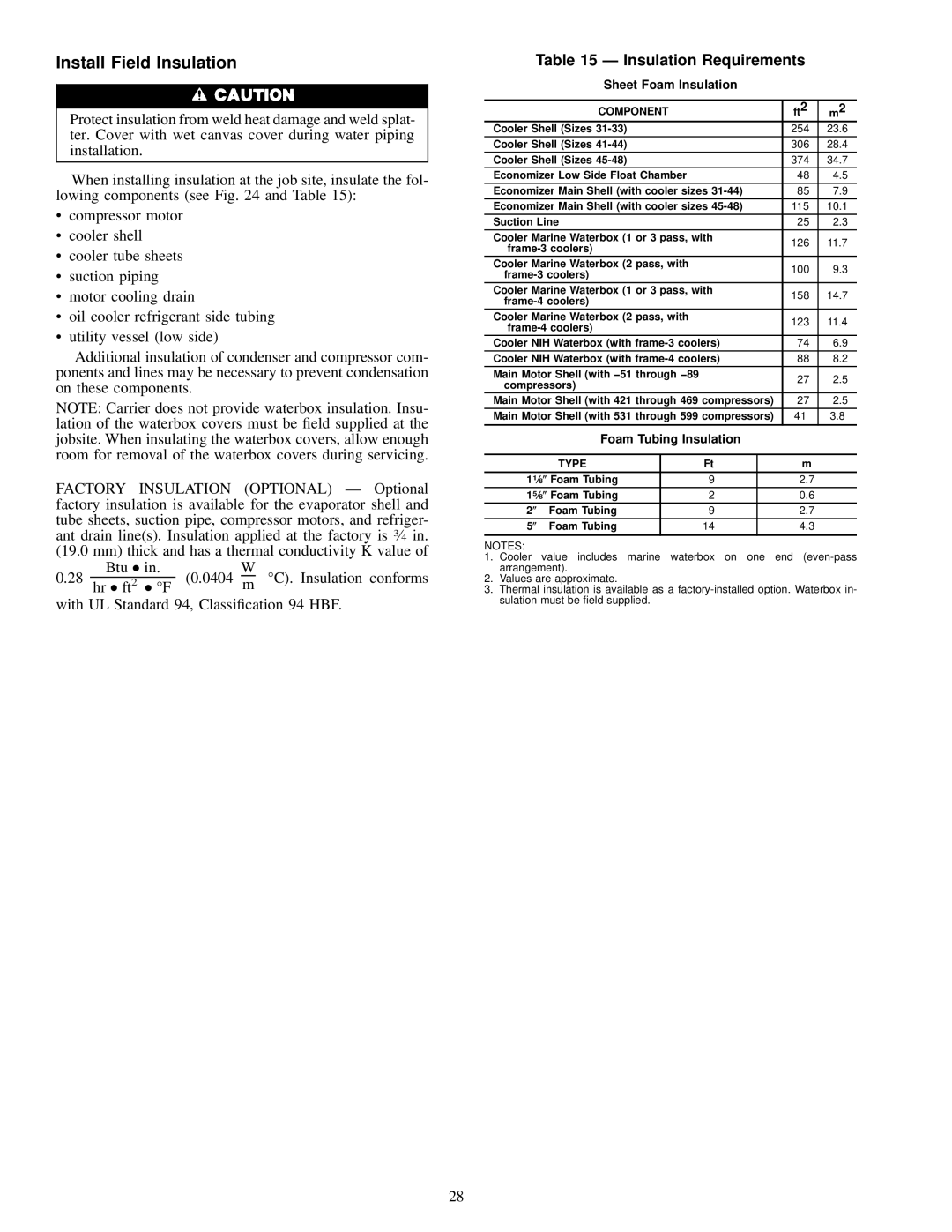

Table 15 Ð Insulation Requirements

Sheet Foam Insulation

|

| COMPONENT |

|

| ft2 | m2 | |

| Cooler Shell (Sizes |

|

| 254 | 23.6 | ||

| Cooler Shell (Sizes |

|

| 306 | 28.4 | ||

| Cooler Shell (Sizes |

|

| 374 | 34.7 | ||

| Economizer Low Side Float Chamber |

|

| 48 | 4.5 | ||

| Economizer Main Shell (with cooler sizes | 85 | 7.9 | ||||

| Economizer Main Shell (with cooler sizes | 115 | 10.1 | ||||

| Suction Line |

|

| 25 | 2.3 | ||

| Cooler Marine Waterbox (1 or 3 pass, with | 126 | 11.7 | ||||

|

|

| |||||

|

|

|

|

| |||

| Cooler Marine Waterbox (2 pass, with |

|

| 100 | 9.3 | ||

|

|

| |||||

|

|

|

|

| |||

| Cooler Marine Waterbox (1 or 3 pass, with | 158 | 14.7 | ||||

|

|

| |||||

|

|

|

|

| |||

| Cooler Marine Waterbox (2 pass, with |

|

| 123 | 11.4 | ||

|

|

| |||||

|

|

|

|

| |||

| Cooler NIH Waterbox (with | 74 | 6.9 | ||||

| Cooler NIH Waterbox (with | 88 | 8.2 | ||||

| Main Motor Shell (with −51 through −89 |

|

| 27 | 2.5 | ||

| compressors) |

|

| ||||

|

|

|

|

| |||

| Main Motor Shell (with 421 through 469 compressors) | 27 | 2.5 | ||||

| Main Motor Shell (with 531 through 599 compressors) | 41 | 3.8 | ||||

|

|

|

|

|

|

| |

|

| Foam Tubing Insulation |

|

| |||

|

|

|

|

|

|

|

|

|

| TYPE |

| Ft |

| m |

|

| 11¤8 | Foam Tubing |

| 9 |

| 2.7 |

|

| 15¤8 | Foam Tubing |

| 2 |

| 0.6 |

|

| 2 | Foam Tubing |

| 9 |

| 2.7 |

|

5 | Foam Tubing |

| 14 |

| 4.3 |

| |

|

|

|

|

|

|

|

|

NOTES:

1.Cooler value includes marine waterbox on one end

2.Values are approximate.

3.Thermal insulation is available as a

28