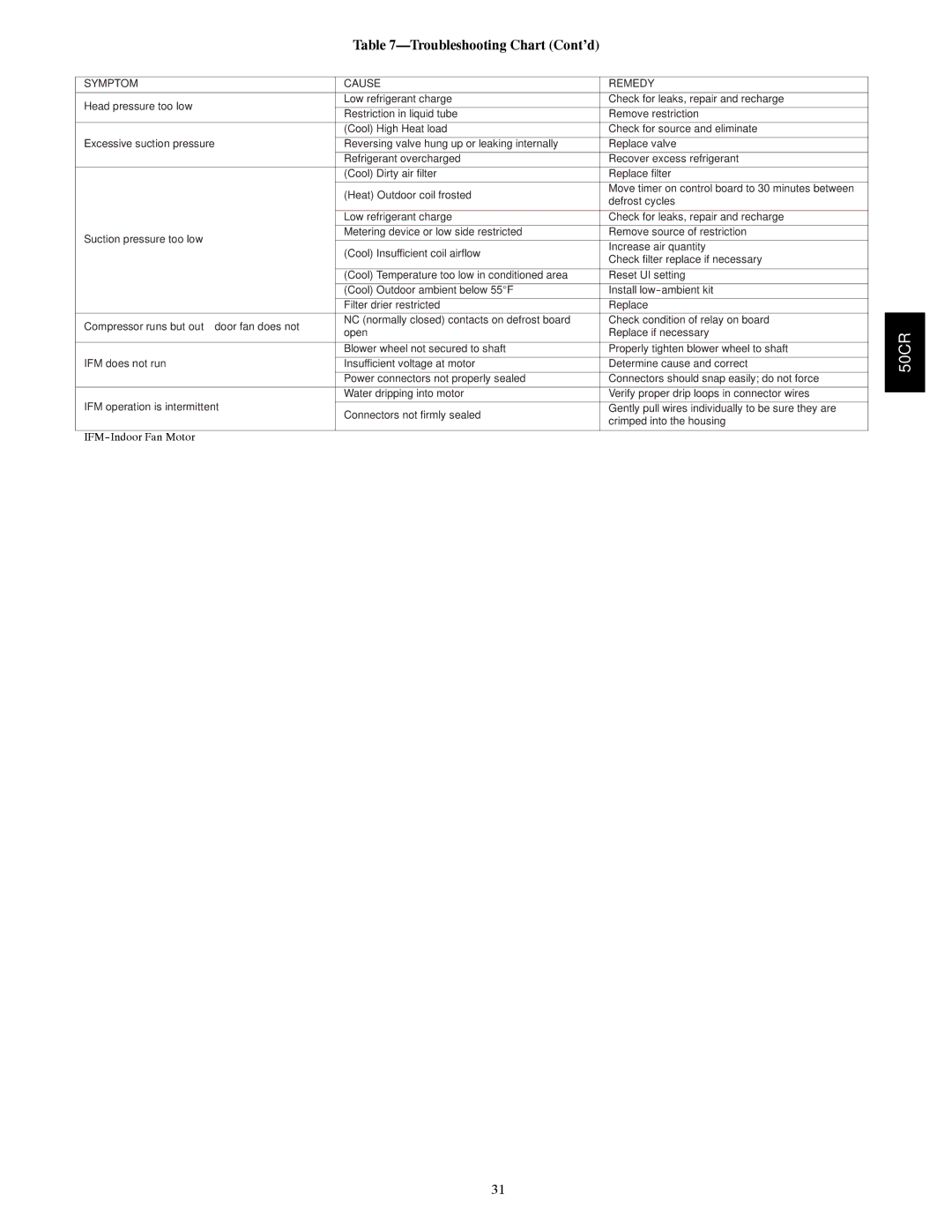

Table 7—Troubleshooting Chart (Cont’d)

SYMPTOM | CAUSE | REMEDY | |

|

|

| |

Head pressure too low | Low refrigerant charge | Check for leaks, repair and recharge | |

Restriction in liquid tube | Remove restriction | ||

| |||

| (Cool) High Heat load | Check for source and eliminate | |

Excessive suction pressure | Reversing valve hung up or leaking internally | Replace valve | |

| Refrigerant overcharged | Recover excess refrigerant | |

| (Cool) Dirty air filter | Replace filter | |

| (Heat) Outdoor coil frosted | Move timer on control board to 30 minutes between | |

| defrost cycles | ||

|

| ||

|

|

| |

| Low refrigerant charge | Check for leaks, repair and recharge | |

Suction pressure too low | Metering device or low side restricted | Remove source of restriction | |

(Cool) Insufficient coil airflow | Increase air quantity | ||

| |||

| Check | ||

|

| ||

|

|

| |

| (Cool) Temperature too low in conditioned area | Reset UI setting | |

| (Cool) Outdoor ambient below 55°F | Install | |

| Filter drier restricted | Replace | |

Compressor runs but outdoor fan does not | NC (normally closed) contacts on defrost board | Check condition of relay on board | |

open | Replace if necessary | ||

| |||

|

|

| |

| Blower wheel not secured to shaft | Properly tighten blower wheel to shaft | |

IFM does not run | Insufficient voltage at motor | Determine cause and correct | |

| Power connectors not properly sealed | Connectors should snap easily; do not force | |

| Water dripping into motor | Verify proper drip loops in connector wires | |

IFM operation is intermittent | Connectors not firmly sealed | Gently pull wires individually to be sure they are | |

| crimped into the housing | ||

|

|

50CR

31