NOTE: There should be a 3 to 6 mm gap between the mating part hub and the bushing flange. If the gap is closed, the bushing is probably the wrong size.

3.With

Blower Fan Performance Adjustment — The unit is supplied with variable sheave drive on the fan motor to adjust for differing airflows at various ESP conditions. Select an airflow requirement on the left side of the table, then move horizontally to right under the required ESP for the sheave turns open, rpm and horsepower for that condition. Fully closed, the sheave will produce the highest static capability (higher rpm).

To change fan speeds from factory settings:

1.Shut off unit power supply.

2.Remove belt from motor sheave.

3.Lift motor assembly.

a50-7135tf

Fig. 24 — Sheave Alignment

4.Loosen the

5.Turn the bolts by hand to the desired position then tighten the

6.Lower the motor assembly.

7.Install the belt.

8.Tension the belt per section below.

9.Restore power to the unit.

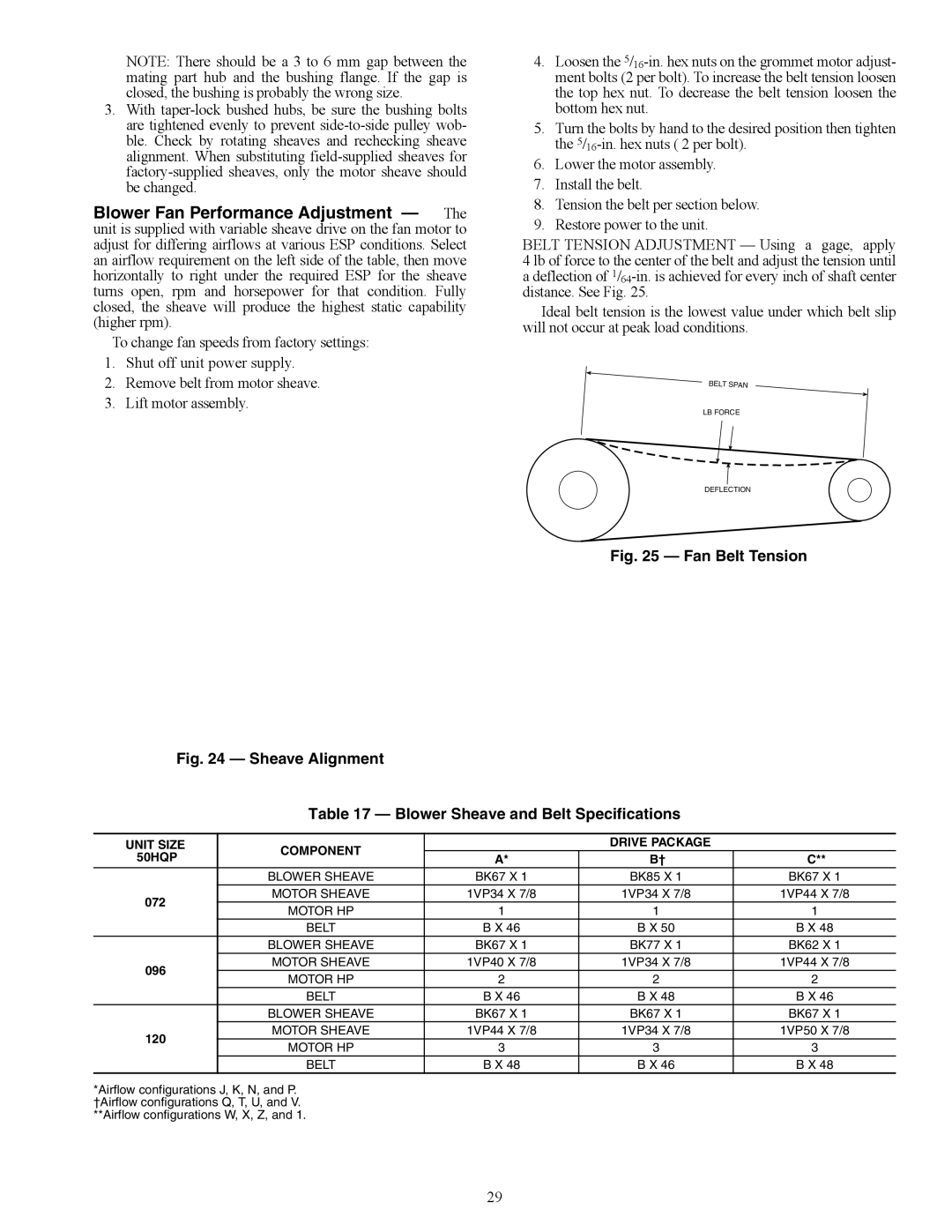

BELT TENSION ADJUSTMENT — Using a gage, apply 4 lb of force to the center of the belt and adjust the tension until a deflection of

Ideal belt tension is the lowest value under which belt slip will not occur at peak load conditions.

LB FORCE

DEFLECTION

a50-7136ef

Fig. 25 — Fan Belt Tension

Table 17 — Blower Sheave and Belt Specifications

UNIT SIZE | COMPONENT |

| DRIVE PACKAGE |

| |

50HQP | A* | B† | C** | ||

| |||||

| BLOWER SHEAVE | BK67 X 1 | BK85 X 1 | BK67 X 1 | |

072 | MOTOR SHEAVE | 1VP34 X 7/8 | 1VP34 X 7/8 | 1VP44 X 7/8 | |

MOTOR HP | 1 | 1 | 1 | ||

| |||||

| BELT | B X 46 | B X 50 | B X 48 | |

| BLOWER SHEAVE | BK67 X 1 | BK77 X 1 | BK62 X 1 | |

096 | MOTOR SHEAVE | 1VP40 X 7/8 | 1VP34 X 7/8 | 1VP44 X 7/8 | |

MOTOR HP | 2 | 2 | 2 | ||

| |||||

| BELT | B X 46 | B X 48 | B X 46 | |

| BLOWER SHEAVE | BK67 X 1 | BK67 X 1 | BK67 X 1 | |

120 | MOTOR SHEAVE | 1VP44 X 7/8 | 1VP34 X 7/8 | 1VP50 X 7/8 | |

MOTOR HP | 3 | 3 | 3 | ||

| |||||

| BELT | B X 48 | B X 46 | B X 48 |

*Airflow configurations J, K, N, and P. †Airflow configurations Q, T, U, and V. **Airflow configurations W, X, Z, and 1.

29