especially important in areas where painting, plastering, or spraying of fireproof material, etc. is not yet complete. Foreign material that is allowed to accumulate within the units can pre- vent proper

Before installing any of the system components, be sure to examine each pipe, fitting, and valve, and remove any dirt or foreign material found in or on these components.

![]() CAUTION

CAUTION

DO NOT store or install units in corrosive environments or in locations subject to temperature or humidity extremes (e.g., attics, garages, rooftops, etc.). Corrosive conditions and high temperature or humidity can significantly reduce performance, reliability, and service life. Always move units in an upright position. Tilting units on their sides may cause equipment damage.

INSPECT UNIT — To prepare the unit for installation, com- plete the procedures listed below:

1.Compare the electrical data on the unit nameplate with ordering and shipping information to verify that the correct unit has been shipped.

2.Do not remove the packaging until the unit is ready for installation.

3.Verify that the unit’s refrigerant tubing is free of kinks or dents, and that it does not touch other unit components.

4.Inspect all electrical connections. Be sure connections are clean and tight at their terminations.

5.Loosen compressor bolts until the compressor rides freely on springs. Remove shipping restraints.

6.Remove the four 6 mm (1/4 in.) shipping bolts from com- pressor support plate (two bolts on each side) to maxi- mize vibration and sound alternation.

![]() CAUTION

CAUTION

Failure to remove shipping brackets from

7.Remove any blower support cardboard from inlet of the blower.

8.Locate and verify any accessory kit located in compressor and/or blower section.

9.Remove any access panel screws that may be difficult to remove once unit is installed.

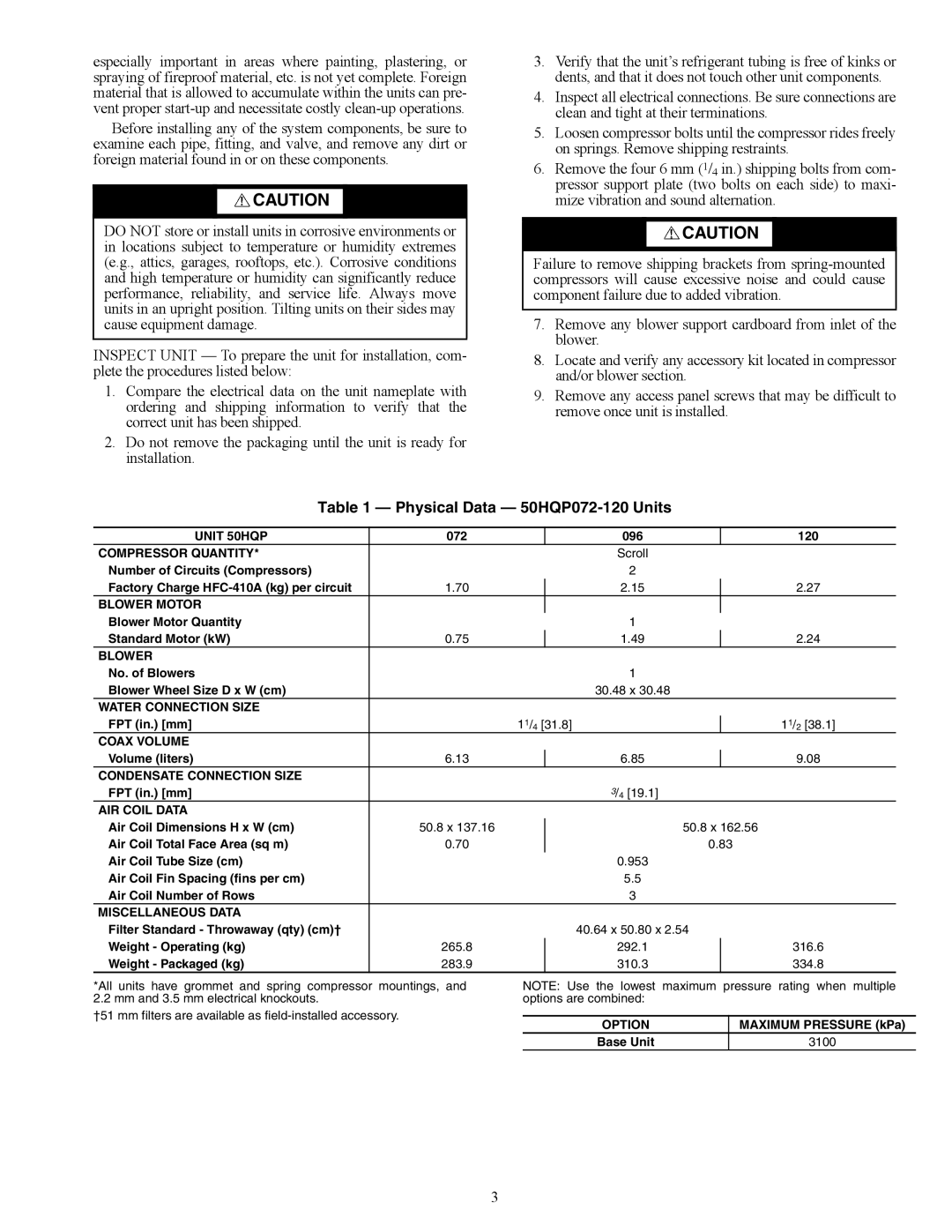

Table 1 — Physical Data — 50HQP072-120 Units

UNIT 50HQP |

| 072 |

|

| 096 |

| 120 |

| |

COMPRESSOR QUANTITY* |

|

|

|

| Scroll |

|

|

|

|

Number of Circuits (Compressors) |

|

| 2 |

|

|

|

| ||

Factory Charge |

| 1.70 |

|

| 2.15 |

| 2.27 |

| |

BLOWER MOTOR |

|

|

|

|

|

|

|

|

|

Blower Motor Quantity |

|

| 1 |

|

|

|

| ||

Standard Motor (kW) |

| 0.75 |

|

| 1.49 |

| 2.24 |

| |

BLOWER |

|

|

|

|

|

|

|

|

|

No. of Blowers |

|

| 1 |

|

|

|

| ||

Blower Wheel Size D x W (cm) |

|

|

|

| 30.48 x 30.48 |

|

|

|

|

WATER CONNECTION SIZE |

|

|

|

|

|

|

|

|

|

FPT (in.) [mm] |

|

| 11/4 [31.8] |

| 11/2 [38.1] |

| |||

COAX VOLUME |

|

|

|

|

|

|

|

|

|

Volume (liters) |

| 6.13 |

|

| 6.85 |

| 9.08 |

| |

CONDENSATE CONNECTION SIZE |

|

|

|

|

|

|

|

|

|

FPT (in.) [mm] |

|

| 3/4 [19.1] |

|

|

|

| ||

AIR COIL DATA |

|

|

|

|

|

|

|

|

|

Air Coil Dimensions H x W (cm) |

| 50.8 x 137.16 |

|

|

| 50.8 x 162.56 | |||

Air Coil Total Face Area (sq m) |

| 0.70 |

|

|

| 0.83 |

| ||

Air Coil Tube Size (cm) |

|

| 0.953 |

|

|

|

| ||

Air Coil Fin Spacing (fins per cm) |

|

| 5.5 |

|

|

|

| ||

Air Coil Number of Rows |

|

| 3 |

|

|

|

| ||

MISCELLANEOUS DATA |

|

|

|

|

|

|

|

|

|

Filter Standard - Throwaway (qty) (cm)† |

|

|

|

| 40.64 x 50.80 x 2.54 | ||||

Weight - Operating (kg) |

| 265.8 |

|

| 292.1 |

| 316.6 |

| |

Weight - Packaged (kg) |

| 283.9 |

|

| 310.3 |

| 334.8 |

| |

*All units have grommet and spring compressor mountings, and |

| NOTE: Use the lowest maximum pressure rating when multiple | |||||||

2.2 mm and 3.5 mm electrical knockouts. |

|

| options are combined: |

|

|

|

| ||

†51 mm filters are available as |

|

|

|

|

|

|

|

| |

|

|

| OPTION |

|

| MAXIMUM PRESSURE (kPa) | |||

|

|

|

|

|

|

| |||

|

|

|

|

| Base Unit |

|

| 3100 |

|

3