Filters — Filters must be clean for maximum performance. Inspect filters every month under normal operating conditions. replace when necessary.

IMPORTANT: Units should never be operated with- out a filter.

Washable, high efficiency, electrostatic filters, when dirty, can exhibit a very high pressure drop for the fan motor and re- duce air flow, resulting in poor performance. It is especially im- portant to provide consistent washing of these filters (in the op- posite direction of the normal air flow) once per month using a high pressure wash.

Water Coil — Keep all air out of the water coil. Check open loop systems to be sure the well head is not allowing air to infiltrate the water line. Always keep lines airtight.

DIRECT GROUND WATER APPLICATIONS — If the system is installed in an area with a known high mineral con- tent (125 ppm or greater) in the water, it is best to establish a periodic maintenance schedule with the owner so the coil can be checked regularly.

Should periodic coil cleaning be necessary, use standard coil cleaning procedures, which are compatible with the heat exchanger material and copper water lines. Generally, the more water flowing through the unit, the less chance for scaling. Therefore, 1.6 L/m per kW is recommended as a minimum flow. Minimum flow rate for entering water temperatures be- low 10.0 C is 2.2 L/m per kW.

ALL OTHER WATER LOOP APPLICATIONS — Gener- ally, water coil maintenance is not needed for closed loop sys- tems. However, if the piping is known to have high dirt or de- bris content, it is best to establish a periodic maintenance schedule with the owner so the water coil can be checked regu- larly. Dirty installations are typically the result of deterioration of iron or galvanized piping or components in the system. Open cooling towers requiring heavy chemical treatment and mineral buildup through water use can also contribute to higher maintenance. Should periodic coil cleaning be necessary, use standard coil cleaning procedures, which are compatible with both the heat exchanger material and copper water lines. Gen- erally, the more water flowing through the unit, the less chance for scaling. However, flow rates over 3.9 L/m per kW can pro- duce water (or debris) velocities that can erode the heat ex- changer wall and ultimately produce leaks.

comb of the correct tooth spacing when straightening mashed or bent coil fins.

Condenser Cleaning —

Local water conditions may cause excessive fouling or pitting of tubes. Condenser tubes should therefore be cleaned at least once a year, or more often if the water is contaminated.

Proper water treatment can minimize tube fouling and pitting. If such conditions are anticipated, water treatment analysis is recommended. Refer to the Carrier System Design Manual, Part 5, for general water conditioning information.

![]() CAUTION

CAUTION

Follow all safety codes. Wear safety glasses and rubber gloves when using inhibited hydrochloric acid solution. Observe and follow acid manufacturer’s instructions. Fail- ure to follow these safety precautions could result in per- sonal injury or equipment or property damage.

Clean condensers with an inhibited hydrochloric acid solu- tion. The acid can stain hands and clothing, damage concrete, and, without inhibitor, damage steel. Cover surroundings to guard against splashing. Vapors from vent pipe are not harmful, but take care to prevent liquid from being carried over by the gases.

Warm solution acts faster, but cold solution is just as effec- tive if applied for a longer period.

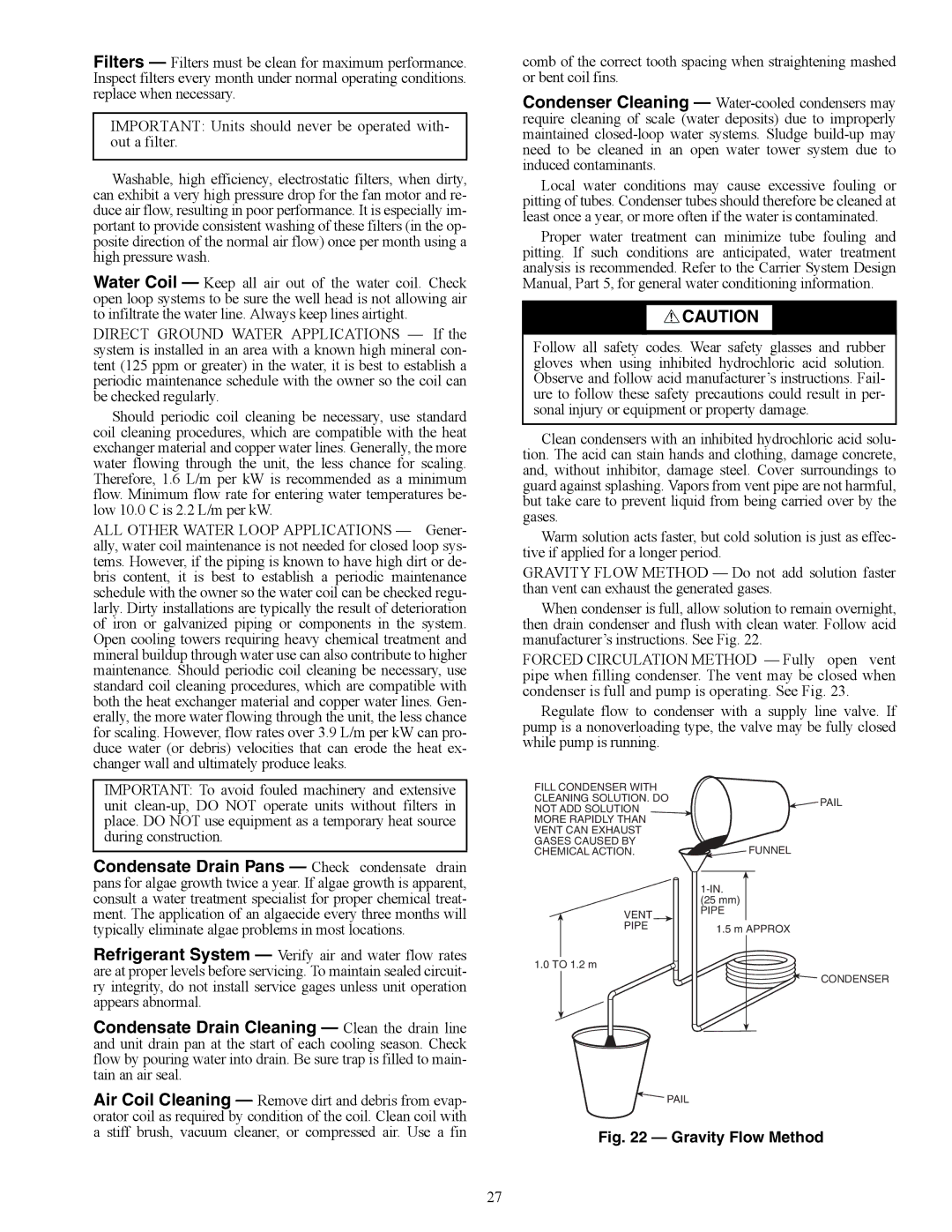

GRAVITY FLOW METHOD — Do not add solution faster than vent can exhaust the generated gases.

When condenser is full, allow solution to remain overnight, then drain condenser and flush with clean water. Follow acid manufacturer’s instructions. See Fig. 22.

FORCED CIRCULATION METHOD — Fully open vent pipe when filling condenser. The vent may be closed when condenser is full and pump is operating. See Fig. 23.

Regulate flow to condenser with a supply line valve. If pump is a nonoverloading type, the valve may be fully closed while pump is running.

IMPORTANT: To avoid fouled machinery and extensive unit

Condensate Drain Pans — Check condensate drain pans for algae growth twice a year. If algae growth is apparent, consult a water treatment specialist for proper chemical treat- ment. The application of an algaecide every three months will typically eliminate algae problems in most locations.

Refrigerant System — Verify air and water flow rates are at proper levels before servicing. To maintain sealed circuit- ry integrity, do not install service gages unless unit operation appears abnormal.

Condensate Drain Cleaning — Clean the drain line and unit drain pan at the start of each cooling season. Check flow by pouring water into drain. Be sure trap is filled to main- tain an air seal.

FILL CONDENSER WITH CLEANING SOLUTION. DO NOT ADD SOLUTION MORE RAPIDLY THAN VENT CAN EXHAUST GASES CAUSED BY CHEMICAL ACTION.

VENT

PIPE

1.0 TO 1.2 m

![]() PAIL

PAIL

![]() FUNNEL

FUNNEL

(25 mm)

PIPE

1.5 m APPROX

![]()

![]() CONDENSER

CONDENSER

Air Coil Cleaning — Remove dirt and debris from evap- orator coil as required by condition of the coil. Clean coil with a stiff brush, vacuum cleaner, or compressed air. Use a fin

![]() PAIL

PAIL

Fig. 22 — Gravity Flow Method a50-8586

27