4.Check the temperature of both supply and discharge water.

5.Air temperature drop across the coil should be checked when compressor is operating. Air temperature drop should be between

Unit Start-Up in Heating Mode

NOTE: Operate the unit in heating cycle after checking the cooling cycle. Allow 5 minutes between tests for the pressure or reversing valve to equalize.

1.Turn thermostat to lowest setting and set thermostat switch to HEAT position.

2.Slowly turn the thermostat to a higher temperature until the compressor activates.

3.Check for warm air delivery at the unit grille within a few minutes after the unit has begun to operate.

4.Check the temperature of both supply and discharge water.

5.Air temperature rise across the coil should be checked when compressor is operating. Air temperature rise should be between

6.Check for vibration, noise and water leaks.

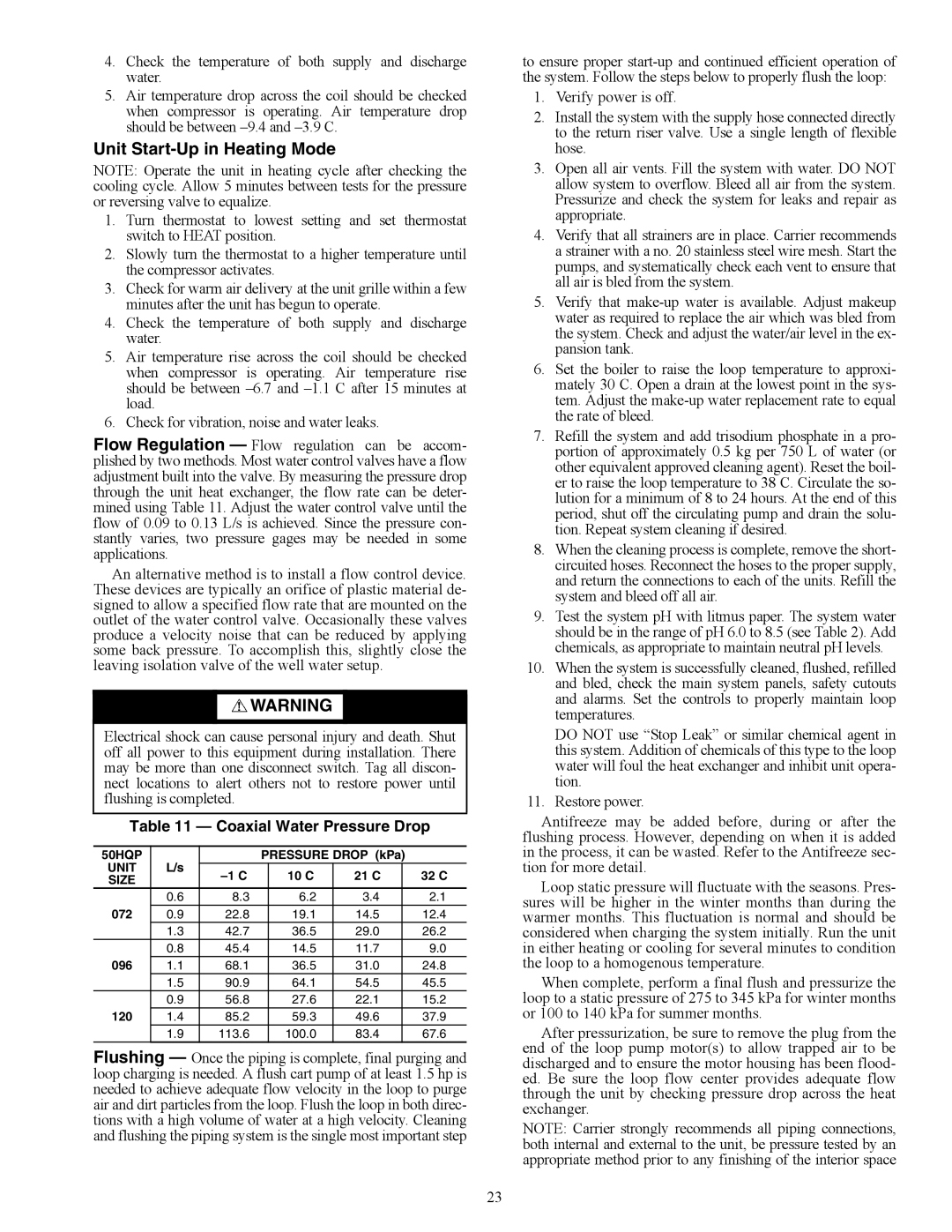

Flow Regulation — Flow regulation can be accom- plished by two methods. Most water control valves have a flow adjustment built into the valve. By measuring the pressure drop through the unit heat exchanger, the flow rate can be deter- mined using Table 11. Adjust the water control valve until the flow of 0.09 to 0.13 L/s is achieved. Since the pressure con- stantly varies, two pressure gages may be needed in some applications.

An alternative method is to install a flow control device. These devices are typically an orifice of plastic material de- signed to allow a specified flow rate that are mounted on the outlet of the water control valve. Occasionally these valves produce a velocity noise that can be reduced by applying some back pressure. To accomplish this, slightly close the leaving isolation valve of the well water setup.

![]() WARNING

WARNING

Electrical shock can cause personal injury and death. Shut off all power to this equipment during installation. There may be more than one disconnect switch. Tag all discon- nect locations to alert others not to restore power until flushing is completed.

Table 11 — Coaxial Water Pressure Drop

50HQP |

|

| PRESSURE DROP (kPa) |

| |||

UNIT | L/s |

|

|

|

|

|

|

| 10 C | 21 C |

| 32 C | |||

SIZE |

|

|

| ||||

|

|

|

|

|

|

| |

| 0.6 | 8.3 |

| 6.2 | 3.4 |

| 2.1 |

072 | 0.9 | 22.8 |

| 19.1 | 14.5 |

| 12.4 |

| 1.3 | 42.7 |

| 36.5 | 29.0 |

| 26.2 |

| 0.8 | 45.4 |

| 14.5 | 11.7 |

| 9.0 |

096 | 1.1 | 68.1 |

| 36.5 | 31.0 |

| 24.8 |

| 1.5 | 90.9 |

| 64.1 | 54.5 |

| 45.5 |

| 0.9 | 56.8 |

| 27.6 | 22.1 |

| 15.2 |

120 | 1.4 | 85.2 |

| 59.3 | 49.6 |

| 37.9 |

| 1.9 | 113.6 |

| 100.0 | 83.4 |

| 67.6 |

Flushing — Once the piping is complete, final purging and loop charging is needed. A flush cart pump of at least 1.5 hp is needed to achieve adequate flow velocity in the loop to purge air and dirt particles from the loop. Flush the loop in both direc- tions with a high volume of water at a high velocity. Cleaning and flushing the piping system is the single most important step

to ensure proper

1.Verify power is off.

2.Install the system with the supply hose connected directly to the return riser valve. Use a single length of flexible hose.

3.Open all air vents. Fill the system with water. DO NOT allow system to overflow. Bleed all air from the system. Pressurize and check the system for leaks and repair as appropriate.

4.Verify that all strainers are in place. Carrier recommends a strainer with a no. 20 stainless steel wire mesh. Start the pumps, and systematically check each vent to ensure that all air is bled from the system.

5.Verify that

6.Set the boiler to raise the loop temperature to approxi- mately 30 C. Open a drain at the lowest point in the sys- tem. Adjust the

7.Refill the system and add trisodium phosphate in a pro- portion of approximately 0.5 kg per 750 L of water (or other equivalent approved cleaning agent). Reset the boil- er to raise the loop temperature to 38 C. Circulate the so- lution for a minimum of 8 to 24 hours. At the end of this period, shut off the circulating pump and drain the solu- tion. Repeat system cleaning if desired.

8.When the cleaning process is complete, remove the short- circuited hoses. Reconnect the hoses to the proper supply, and return the connections to each of the units. Refill the system and bleed off all air.

9.Test the system pH with litmus paper. The system water should be in the range of pH 6.0 to 8.5 (see Table 2). Add chemicals, as appropriate to maintain neutral pH levels.

10.When the system is successfully cleaned, flushed, refilled and bled, check the main system panels, safety cutouts and alarms. Set the controls to properly maintain loop temperatures.

DO NOT use “Stop Leak” or similar chemical agent in this system. Addition of chemicals of this type to the loop water will foul the heat exchanger and inhibit unit opera- tion.

11.Restore power.

Antifreeze may be added before, during or after the flushing process. However, depending on when it is added in the process, it can be wasted. Refer to the Antifreeze sec- tion for more detail.

Loop static pressure will fluctuate with the seasons. Pres- sures will be higher in the winter months than during the warmer months. This fluctuation is normal and should be considered when charging the system initially. Run the unit in either heating or cooling for several minutes to condition the loop to a homogenous temperature.

When complete, perform a final flush and pressurize the loop to a static pressure of 275 to 345 kPa for winter months or 100 to 140 kPa for summer months.

After pressurization, be sure to remove the plug from the end of the loop pump motor(s) to allow trapped air to be discharged and to ensure the motor housing has been flood- ed. Be sure the loop flow center provides adequate flow through the unit by checking pressure drop across the heat exchanger.

NOTE: Carrier strongly recommends all piping connections, both internal and external to the unit, be pressure tested by an appropriate method prior to any finishing of the interior space

23