1.4AirV SYSTEM COMPONENT SPECIFI-

CATIONS

1.4.1 Refrigerant Charge

Standard

Low Profile (All)

1.4.2 Compressor

a. Locked Rotor Amps

64.5AMPS6

b.Locked Rotor Amps

59.0AMPS

c.Fully Loaded Amps

Cooling

d. Fully Loaded Amps

Cooling

Heating

e. Fully Loaded Amps

f.Fully Loaded Amps

1.4.3Compressor

23.6AMPS

1.4.4Thermostat Range (All Free Blow Units)

61° F (16° C) to 89° F (32° C)

1.5 START--UP

Refer to operating instructions in Owners Guide (see Table

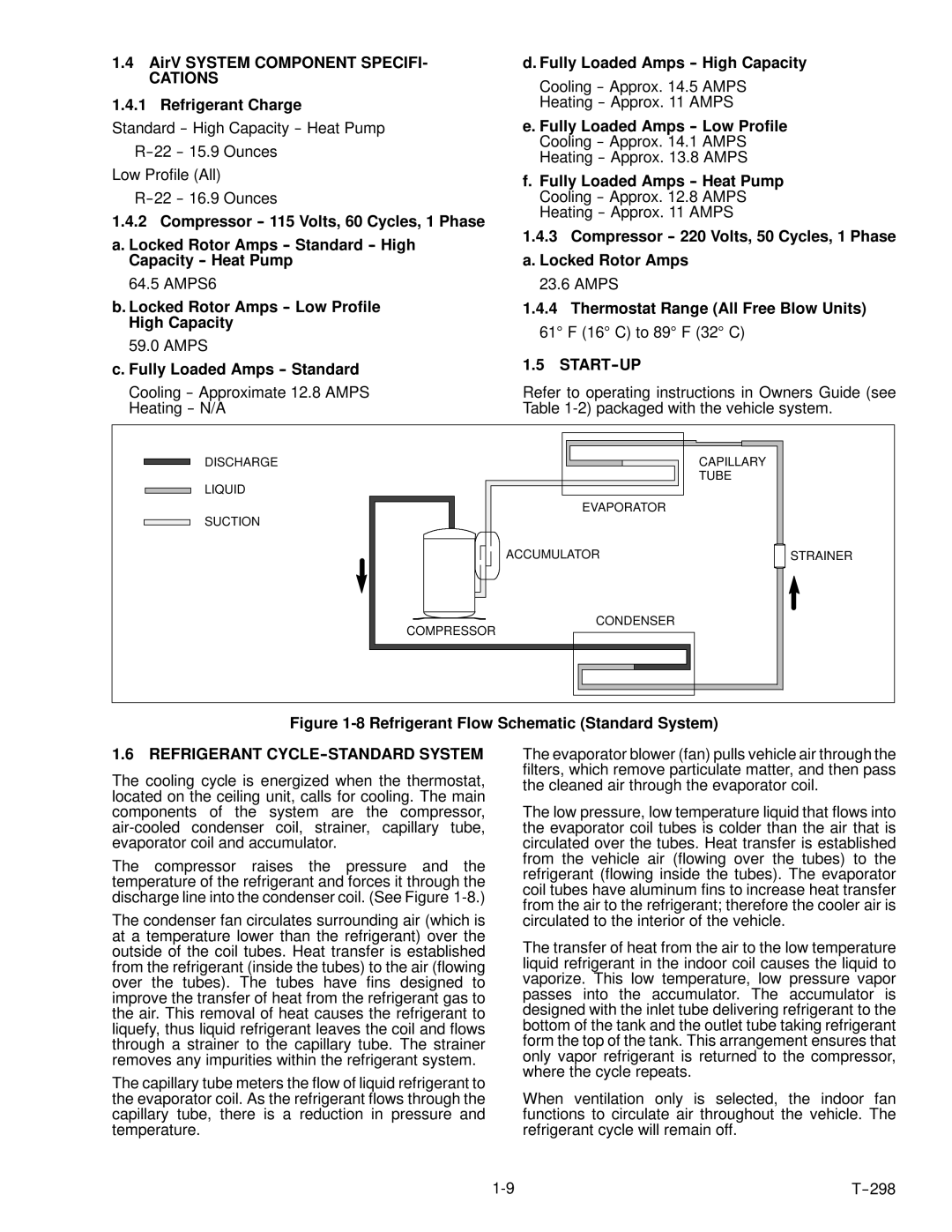

DISCHARGE

LIQUID

SUCTION

|

| CAPILLARY |

|

| TUBE |

| EVAPORATOR |

|

| ACCUMULATOR | STRAINER |

COMPRESSOR | CONDENSER |

|

|

|

Figure 1-8 Refrigerant Flow Schematic (Standard System)

1.6 REFRIGERANT CYCLE--STANDARD SYSTEM

The cooling cycle is energized when the thermostat, located on the ceiling unit, calls for cooling. The main components of the system are the compressor,

The compressor raises the pressure and the temperature of the refrigerant and forces it through the discharge line into the condenser coil. (See Figure

The condenser fan circulates surrounding air (which is at a temperature lower than the refrigerant) over the outside of the coil tubes. Heat transfer is established from the refrigerant (inside the tubes) to the air (flowing over the tubes). The tubes have fins designed to improve the transfer of heat from the refrigerant gas to the air. This removal of heat causes the refrigerant to liquefy, thus liquid refrigerant leaves the coil and flows through a strainer to the capillary tube. The strainer removes any impurities within the refrigerant system.

The capillary tube meters the flow of liquid refrigerant to the evaporator coil. As the refrigerant flows through the capillary tube, there is a reduction in pressure and temperature.

The evaporator blower (fan) pulls vehicle air through the filters, which remove particulate matter, and then pass the cleaned air through the evaporator coil.

The low pressure, low temperature liquid that flows into the evaporator coil tubes is colder than the air that is circulated over the tubes. Heat transfer is established from the vehicle air (flowing over the tubes) to the refrigerant (flowing inside the tubes). The evaporator coil tubes have aluminum fins to increase heat transfer from the air to the refrigerant; therefore the cooler air is circulated to the interior of the vehicle.

The transfer of heat from the air to the low temperature liquid refrigerant in the indoor coil causes the liquid to vaporize. This low temperature, low pressure vapor passes into the accumulator. The accumulator is designed with the inlet tube delivering refrigerant to the bottom of the tank and the outlet tube taking refrigerant form the top of the tank. This arrangement ensures that only vapor refrigerant is returned to the compressor, where the cycle repeats.

When ventilation only is selected, the indoor fan functions to circulate air throughout the vehicle. The refrigerant cycle will remain off.