MIG Welding Set Up

7.If using

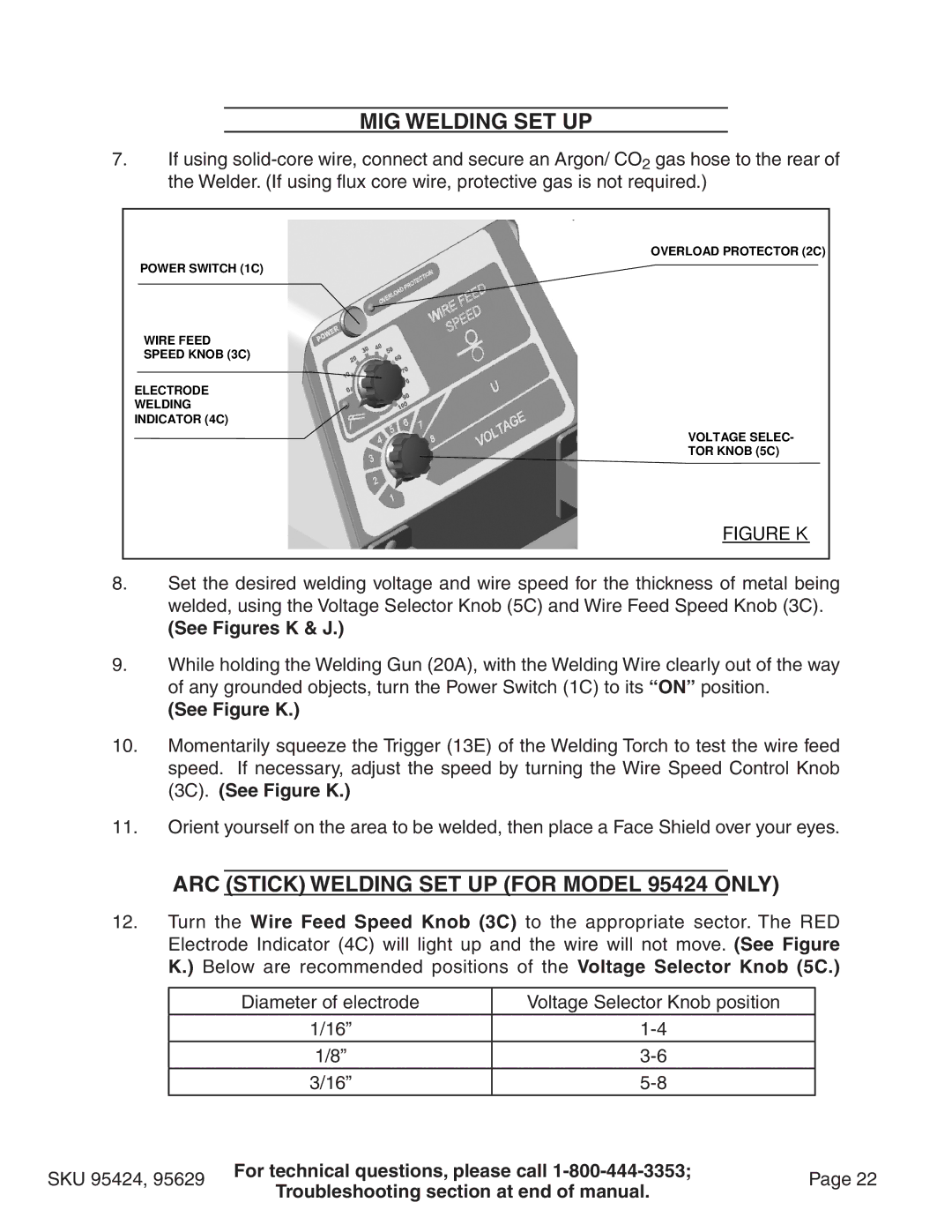

OVERLOAD PROTECTOR (2C) |

POWER SWITCH (1C) |

WIRE FEED |

SPEED KNOB (3C) |

ELECTRODE |

WELDING |

INDICATOR (4C) |

VOLTAGE SELEC- |

TOR KNOB (5C) |

FIGURE K |

8.Set the desired welding voltage and wire speed for the thickness of metal being welded, using the Voltage Selector Knob (5C) and Wire Feed Speed Knob (3C).

(See Figures K & J.)

9.While holding the Welding Gun (20A), with the Welding Wire clearly out of the way of any grounded objects, turn the Power Switch (1C) to its “ON” position.

(See Figure K.)

10.Momentarily squeeze the Trigger (13E) of the Welding Torch to test the wire feed speed. If necessary, adjust the speed by turning the Wire Speed Control Knob (3C). (See Figure K.)

11.Orient yourself on the area to be welded, then place a Face Shield over your eyes.

Arc (Stick) Welding Set Up (for Model 95424 Only)

12.Turn the Wire Feed Speed Knob (3C) to the appropriate sector. The RED Electrode Indicator (4C) will light up and the wire will not move. (See Figure K.) Below are recommended positions of the Voltage Selector Knob (5C.)

Diameter of electrode | Voltage Selector Knob position |

1/16” | |

1/8” | |

3/16” |

SKU 95424, 95629 | For technical questions, please call | Page 22 | |

Troubleshooting section at end of manual. | |||

|

|