WARNING: CO2 displaces oxygen. Strict attention must be observed in the prevention of CO2 (carbon dioxide) gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience tremors which are followed rapidly by loss of consciousness and suffocation.

1.Fully close (clockwise) CO2 cylinder valve.

2.Slowly loosen CO2 regulator assembly coupling nut allowing CO2 pressure to escape, then remove regula- tor assembly from empty CO2 cylinder.

3.Unfasten safety chain and remove empty CO2 cylinder.

WARNING: To avoid personal injury and/or property damage, always secure CO2 cylinder in an upright position with safety chain to prevent it from falling over. Should the shutoff valve become accidentally broken off, CO2 cylinder can cause serious personal injury.

4.Position CO2 cylinder and secure with safety chain.

5.Make sure gasket is in place inside CO2 regulator coupling nut, then install regulator on CO2 cylinder.

6.Open (counterclockwise) CO2 cylinder valve slightly to allow lines to slowly fill with gas, then open valve fully to

7.Check CO2 connections for leaks.

REPLENISHING BEER SUPPLY

(see Figure 2)

1.Close CO2 and beer line shutoff valves for the empty beer keg.

2.Remove beer keg tapper from the empty beer keg.

3.Make sure beer keg tapper and top of the full beer keg are clean, then then install tapper in the keg.

4.Open CO2 and beer line shutoff valves.

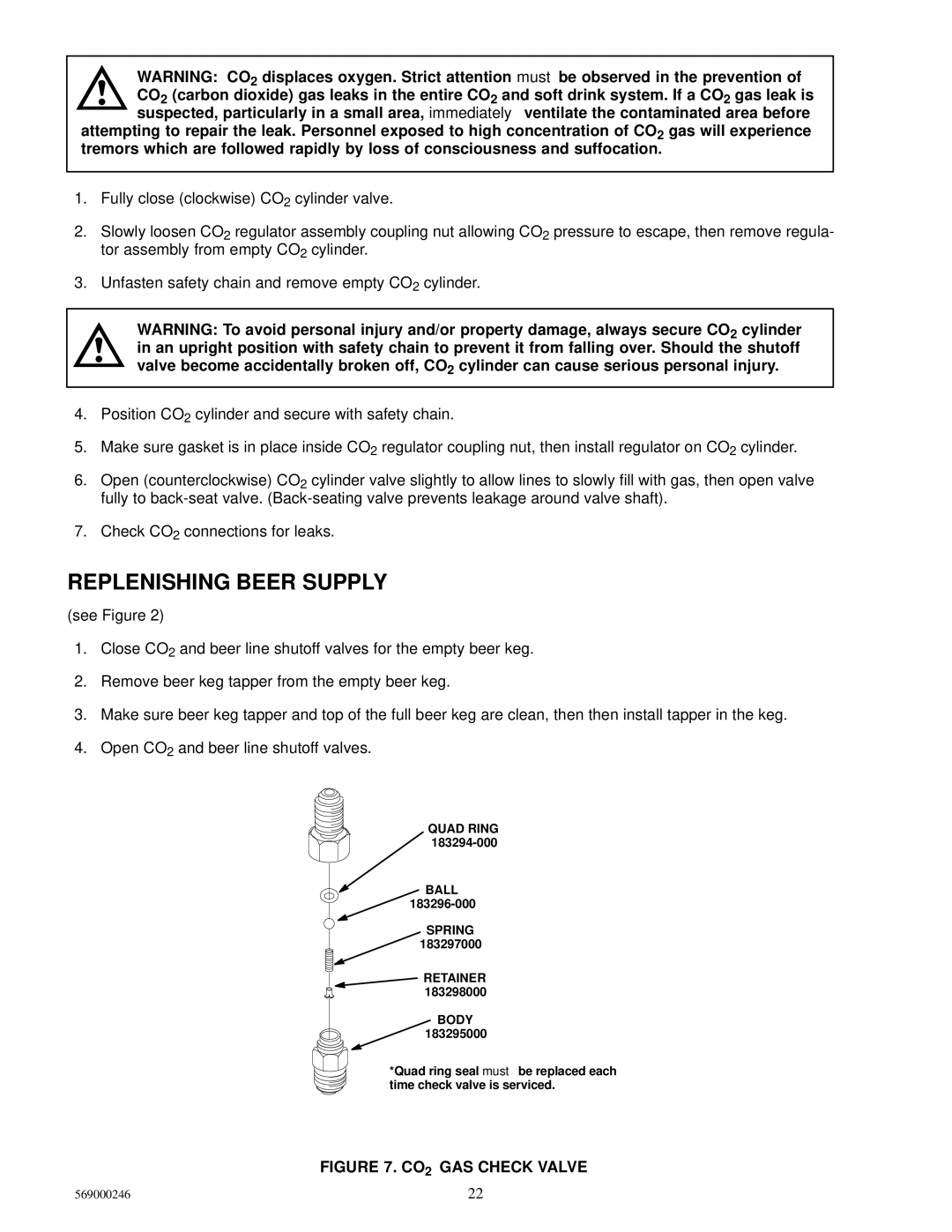

QUAD RING

BALL

SPRING 183297000

RETAINER 183298000

BODY 183295000

*Quad ring seal must be replaced each time check valve is serviced.

FIGURE 7. CO2 GAS CHECK VALVE

569000246 | 22 |