FlavorFusion®/FlavorOverload Training Manual

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to a product system, remove quick disconnects from the applicable product tank, then relieve the system pressure before proceeding. If repairs are to be made to the CO2 system, stop dispensing, shut off the CO2 supply, then relieve the system

pressure before proceeding. If repairs are to be made to the electrical system, make sure electrical power is disconnected from the unit or the key switch has been turned off.

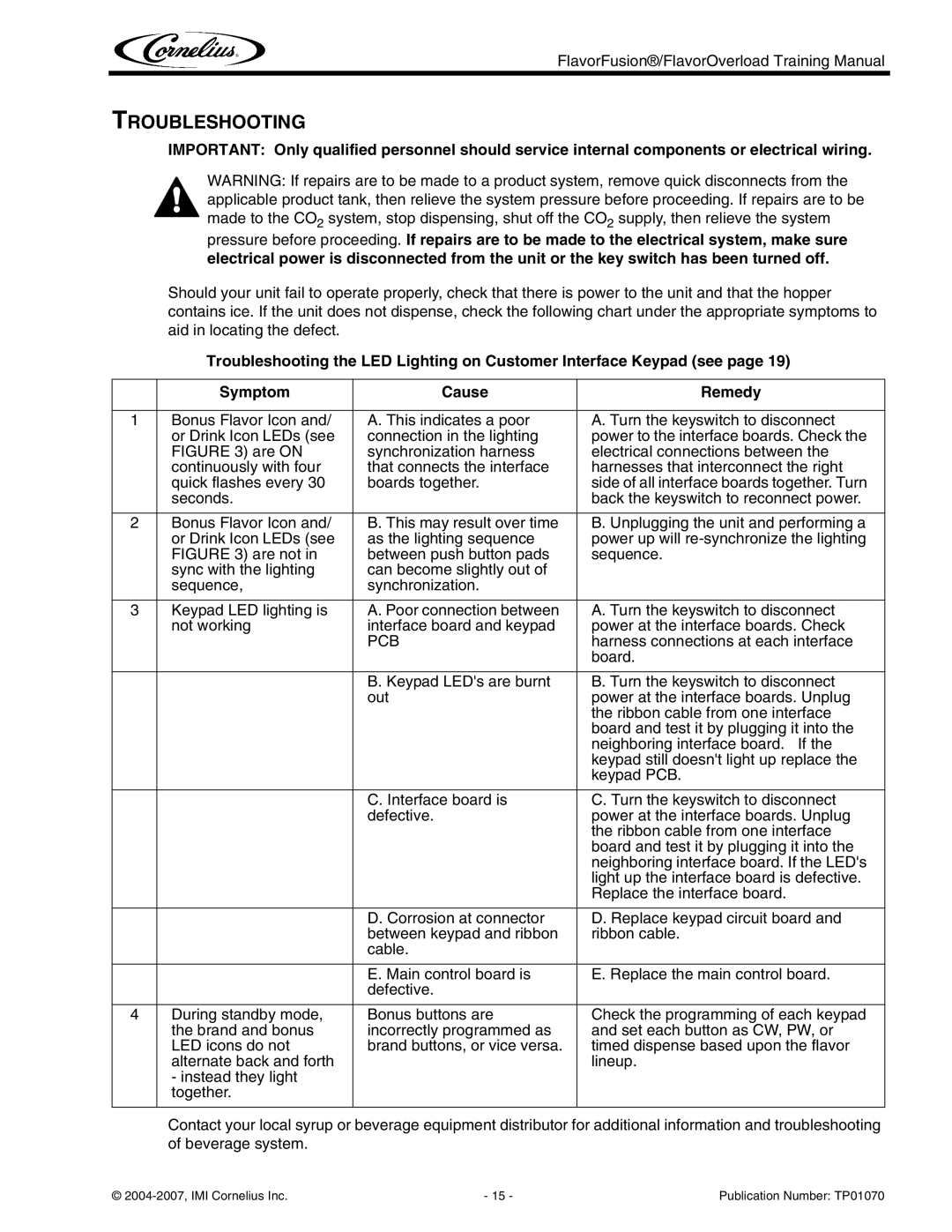

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If the unit does not dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

Troubleshooting the LED Lighting on Customer Interface Keypad (see page 19)

| Symptom | Cause | Remedy |

|

|

|

|

1 | Bonus Flavor Icon and/ | A. This indicates a poor | A. Turn the keyswitch to disconnect |

| or Drink Icon LEDs (see | connection in the lighting | power to the interface boards. Check the |

| FIGURE 3) are ON | synchronization harness | electrical connections between the |

| continuously with four | that connects the interface | harnesses that interconnect the right |

| quick flashes every 30 | boards together. | side of all interface boards together. Turn |

| seconds. |

| back the keyswitch to reconnect power. |

|

|

|

|

2 | Bonus Flavor Icon and/ | B. This may result over time | B. Unplugging the unit and performing a |

| or Drink Icon LEDs (see | as the lighting sequence | power up will |

| FIGURE 3) are not in | between push button pads | sequence. |

| sync with the lighting | can become slightly out of |

|

| sequence, | synchronization. |

|

|

|

|

|

3 | Keypad LED lighting is | A. Poor connection between | A. Turn the keyswitch to disconnect |

| not working | interface board and keypad | power at the interface boards. Check |

|

| PCB | harness connections at each interface |

|

|

| board. |

|

|

|

|

|

| B. Keypad LED's are burnt | B. Turn the keyswitch to disconnect |

|

| out | power at the interface boards. Unplug |

|

|

| the ribbon cable from one interface |

|

|

| board and test it by plugging it into the |

|

|

| neighboring interface board. If the |

|

|

| keypad still doesn't light up replace the |

|

|

| keypad PCB. |

|

|

|

|

|

| C. Interface board is | C. Turn the keyswitch to disconnect |

|

| defective. | power at the interface boards. Unplug |

|

|

| the ribbon cable from one interface |

|

|

| board and test it by plugging it into the |

|

|

| neighboring interface board. If the LED's |

|

|

| light up the interface board is defective. |

|

|

| Replace the interface board. |

|

|

|

|

|

| D. Corrosion at connector | D. Replace keypad circuit board and |

|

| between keypad and ribbon | ribbon cable. |

|

| cable. |

|

|

|

|

|

|

| E. Main control board is | E. Replace the main control board. |

|

| defective. |

|

|

|

|

|

4 | During standby mode, | Bonus buttons are | Check the programming of each keypad |

| the brand and bonus | incorrectly programmed as | and set each button as CW, PW, or |

| LED icons do not | brand buttons, or vice versa. | timed dispense based upon the flavor |

| alternate back and forth |

| lineup. |

-instead they light together.

Contact your local syrup or beverage equipment distributor for additional information and troubleshooting of beverage system.

© | - 15 - | Publication Number: TP01070 |