(NOTE 2)

HONEYWELL

L8124E

HIGH LIMIT

2

H O N E Y W E LL

V R 82 04/V R 83 04

S E R IE S G A S VA LV E S (C W I06 9 - 345)

| + | R O B E R T S H A W |

T H | 7 0 00 D E R H C | |

| G A S VA LV E |

T R | (C W I37 9) |

LOW | LESS VENT | MAIN VALVE |

LIMIT |

| |

| DAMPER | PILOT VALVE |

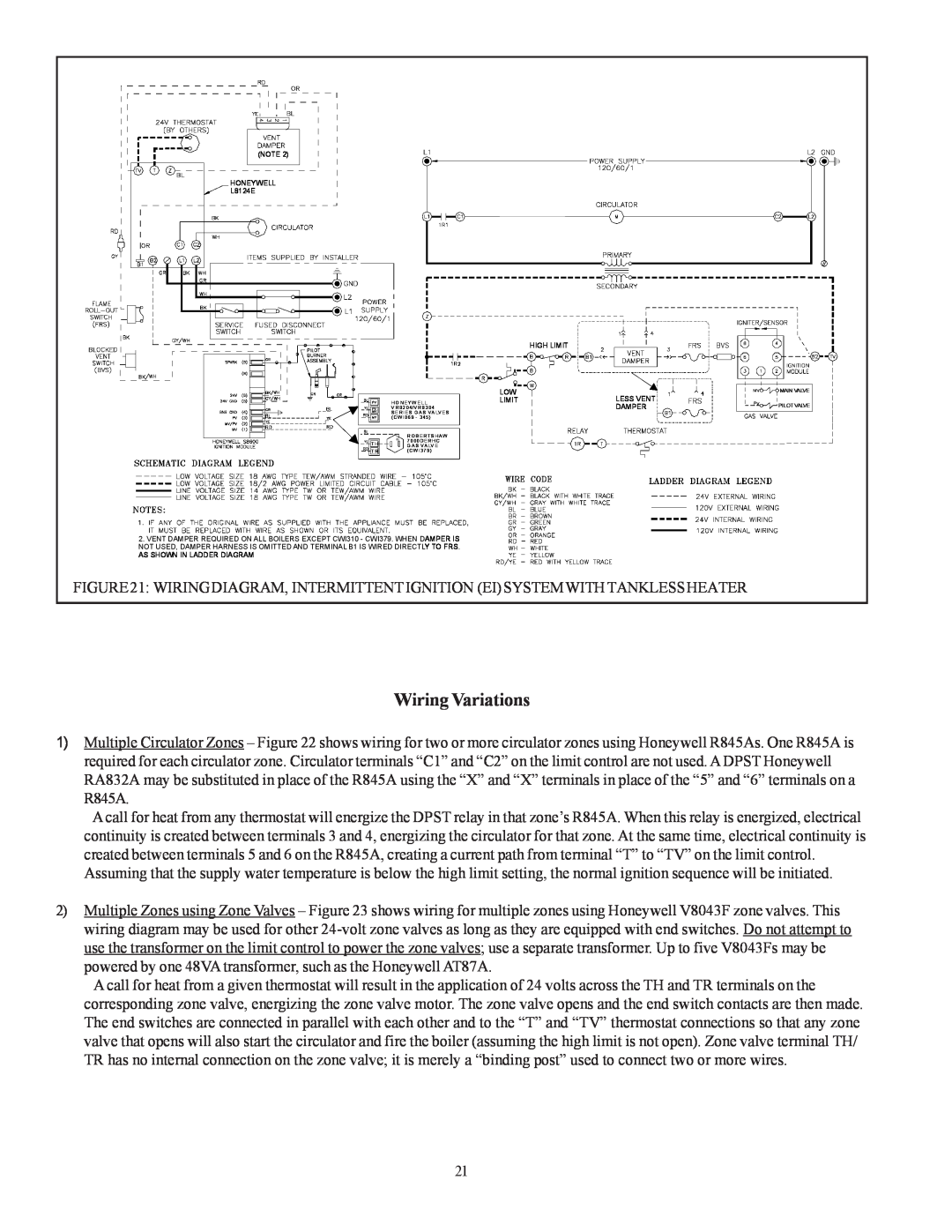

2.VENT DAMPER REQUIRED ON ALL BOILERS EXCEPT CWI310 - CWI379. WHEN DAMPER IS NOT USED, DAMPER HARNESS IS OMITTED AND TERMINAL B1 IS WIRED DIRECTLY TO FRS. AS SHOWN IN LADDER DIAGRAM

FIGURE21: WIRINGDIAGRAM, INTERMITTENTIGNITION (EI)SYSTEMWITHTANKLESSHEATER

Wiring Variations

1)Multiple Circulator Zones – Figure 22 shows wiring for two or more circulator zones using Honeywell R845As. One R845A is required for each circulator zone. Circulator terminals “C1” and “C2” on the limit control are not used. A DPST Honeywell RA832A may be substituted in place of the R845A using the “X” and “X” terminals in place of the “5” and “6” terminals on a R845A.

A call for heat from any thermostat will energize the DPST relay in that zone’s R845A. When this relay is energized, electrical continuity is created between terminals 3 and 4, energizing the circulator for that zone. At the same time, electrical continuity is created between terminals 5 and 6 on the R845A, creating a current path from terminal “T” to “TV” on the limit control.

Assuming that the supply water temperature is below the high limit setting, the normal ignition sequence will be initiated.

2)Multiple Zones using Zone Valves – Figure 23 shows wiring for multiple zones using Honeywell V8043F zone valves. This wiring diagram may be used for other

A call for heat from a given thermostat will result in the application of 24 volts across the TH and TR terminals on the corresponding zone valve, energizing the zone valve motor. The zone valve opens and the end switch contacts are then made. The end switches are connected in parallel with each other and to the “T” and “TV” thermostat connections so that any zone valve that opens will also start the circulator and fire the boiler (assuming the high limit is not open). Zone valve terminal TH/ TR has no internal connection on the zone valve; it is merely a “binding post” used to connect two or more wires.

22

21