5.Using a 3/16″ Allen wrench (J) Fig. 64, turn adjustment screws (K) Figs. 61 and 64 to remove all “play.” NOTE: DO

NOT OVERTIGHTEN ADJUSTMENT SCREWS (K). THIS CAN DAMAGE BEARINGS.

![]() WARNING: DO NOT LOOSEN ADJUSTMENT SCREWS (K) MORE THAN 1/2 TURN. THE CUTTING-

WARNING: DO NOT LOOSEN ADJUSTMENT SCREWS (K) MORE THAN 1/2 TURN. THE CUTTING-

HEAD MAY FALL FROM THE TRACK ARM.

6.Tighten two hex nuts which were loosened in STEP 4, and check

7.When adjustments are complete, replace plastic plug which was removed in STEP 2.

ADJUSTING TENSION ON ELEVATING COLUMN

Elevating column tension is preset at the factory. It can be adjusted to remove any “play” which may develop after extended use. Adjustments can be made as follows:

1.DISCONNECT TOOL FROM POWER SOURCE.

2.Loosen hex nuts (A) Fig. 65, and gib adjustment screws (C).

3.Adjustment to column base (B) Fig. 65, is made by loosening hex nuts (D) and turning screws (E) until column base wraps around column securely and can be raised or lowered without binding. Then tighten hex nuts (D) against column base.

4.After all movement between column base (B) Fig. 65, and elevating column (F) is removed, tighten gib and adjustment screws (C) against gib (H) until all

CHANGING POSITION OF TRACK ARM CLAMPING HANDLE

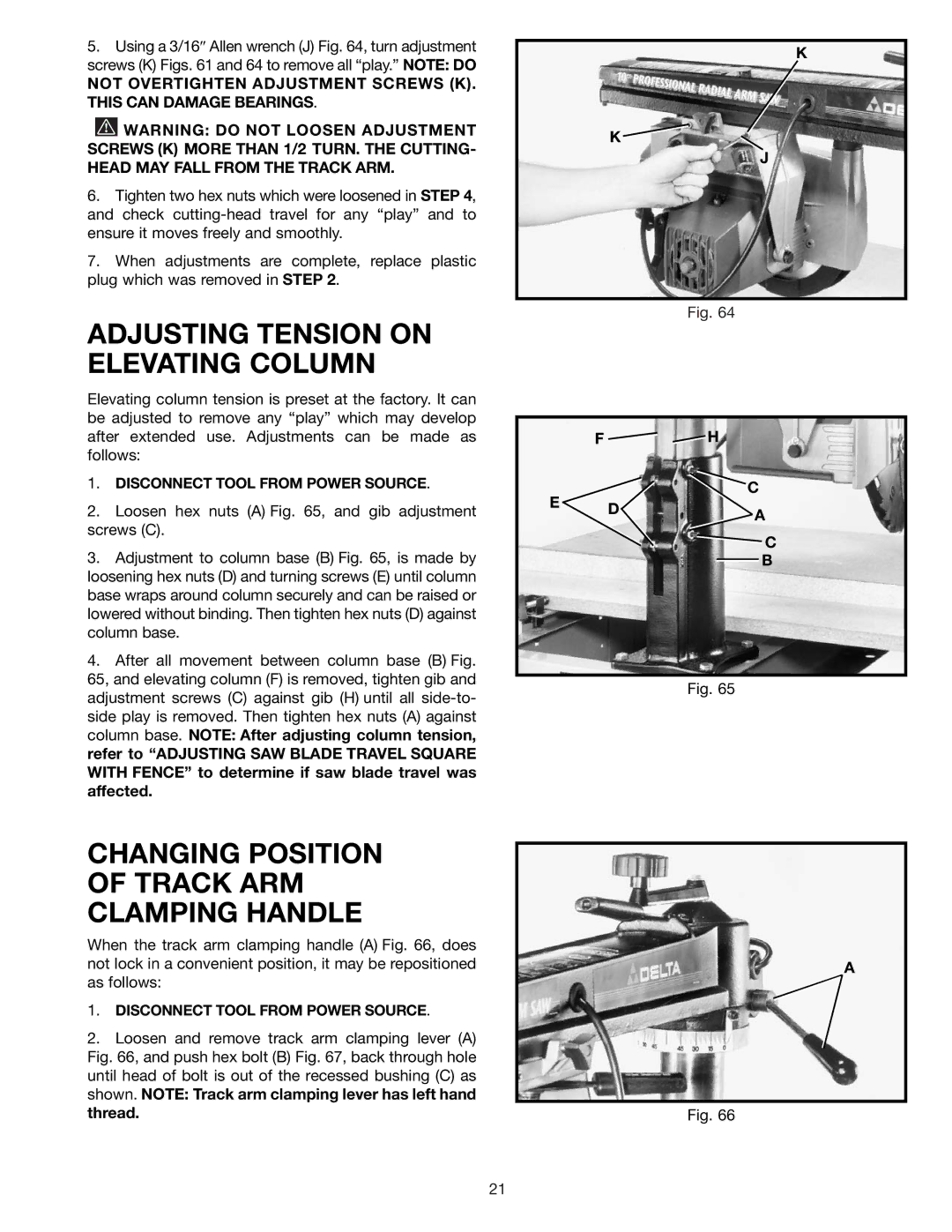

When the track arm clamping handle (A) Fig. 66, does not lock in a convenient position, it may be repositioned as follows:

1.DISCONNECT TOOL FROM POWER SOURCE.

2.Loosen and remove track arm clamping lever (A) Fig. 66, and push hex bolt (B) Fig. 67, back through hole until head of bolt is out of the recessed bushing (C) as shown. NOTE: Track arm clamping lever has left hand thread.

K

K ![]()

J

Fig. 64

F ![]()

![]() H

H

C

E D![]() A

A

C

B

Fig. 65

A

Fig. 66

21