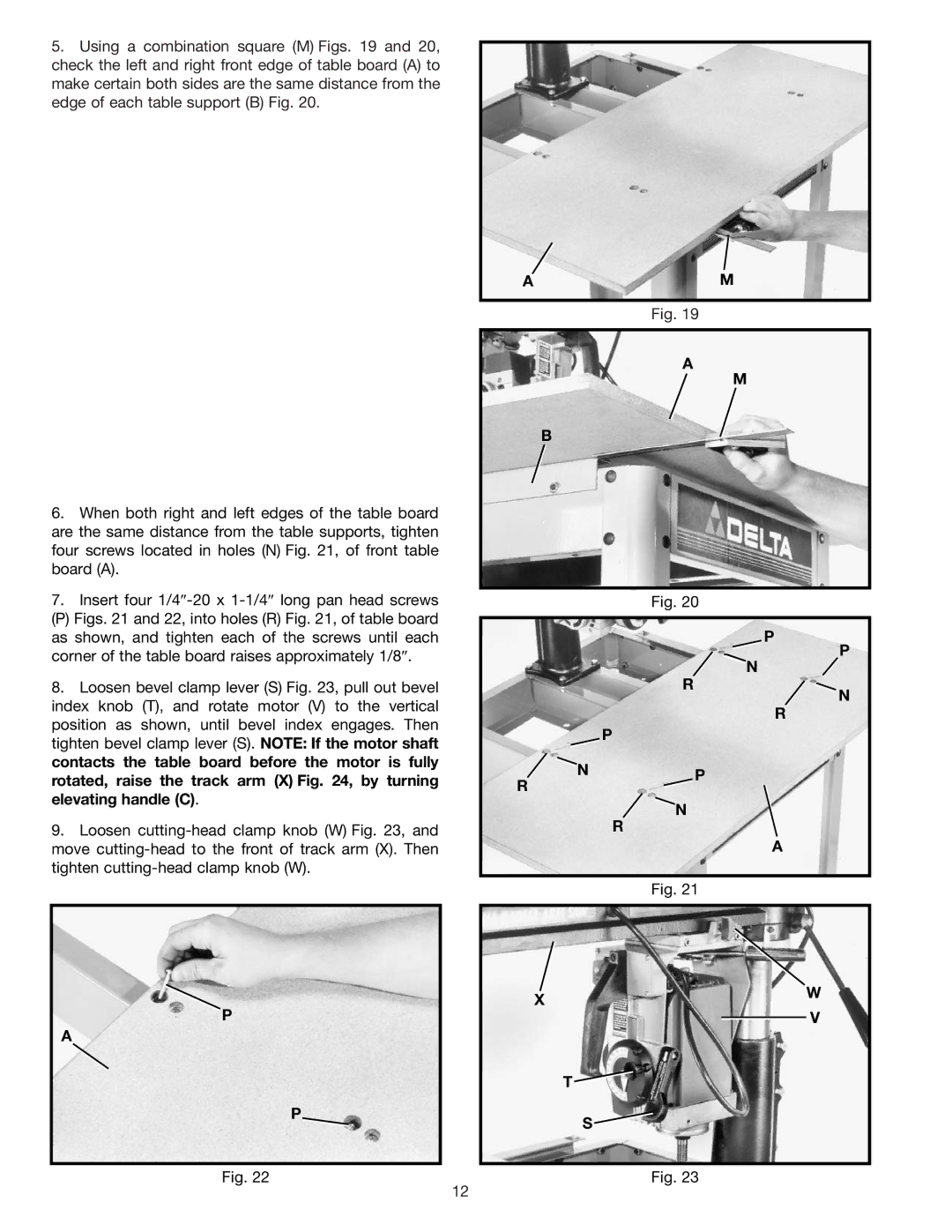

5.Using a combination square (M) Figs. 19 and 20, check the left and right front edge of table board (A) to make certain both sides are the same distance from the edge of each table support (B) Fig. 20.

6. | When both right and left edges of the table board |

are the same distance from the table supports, tighten | |

four screws located in holes (N) Fig. 21, of front table | |

board (A). | |

7. | Insert four |

(P) Figs. 21 and 22, into holes (R) Fig. 21, of table board | |

as shown, and tighten each of the screws until each | |

corner of the table board raises approximately 1/8″. | |

8. | Loosen bevel clamp lever (S) Fig. 23, pull out bevel |

index knob (T), and rotate motor (V) to the vertical | |

AM

Fig. 19

A

M

B

Fig. 20

P

P

N

R

N

position as shown, until bevel index engages. Then |

tighten bevel clamp lever (S). NOTE: If the motor shaft |

contacts the table board before the motor is fully |

rotated, raise the track arm (X) Fig. 24, by turning |

elevating handle (C). |

9. Loosen |

move |

tighten |

R

R

P

NP

![]() N R

N R

A

Fig. 21

P

A

P

Fig. 22

XW

V

T ![]()

S

Fig. 23

12