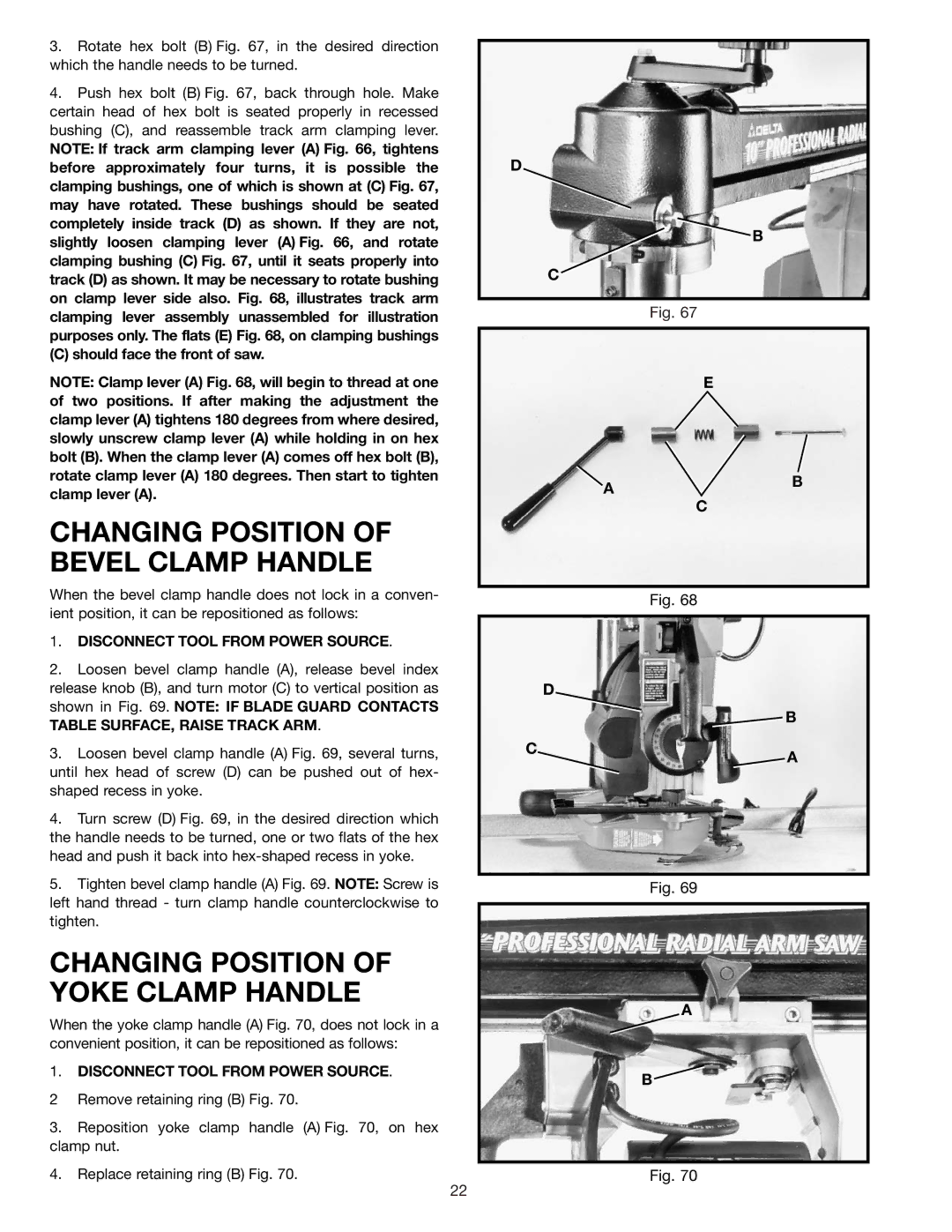

3.Rotate hex bolt (B) Fig. 67, in the desired direction which the handle needs to be turned.

4.Push hex bolt (B) Fig. 67, back through hole. Make certain head of hex bolt is seated properly in recessed bushing (C), and reassemble track arm clamping lever.

NOTE: If track arm clamping lever (A) Fig. 66, tightens before approximately four turns, it is possible the clamping bushings, one of which is shown at (C) Fig. 67, may have rotated. These bushings should be seated completely inside track (D) as shown. If they are not, slightly loosen clamping lever (A) Fig. 66, and rotate clamping bushing (C) Fig. 67, until it seats properly into track (D) as shown. It may be necessary to rotate bushing on clamp lever side also. Fig. 68, illustrates track arm clamping lever assembly unassembled for illustration purposes only. The flats (E) Fig. 68, on clamping bushings

(C) should face the front of saw.

NOTE: Clamp lever (A) Fig. 68, will begin to thread at one of two positions. If after making the adjustment the clamp lever (A) tightens 180 degrees from where desired, slowly unscrew clamp lever (A) while holding in on hex bolt (B). When the clamp lever (A) comes off hex bolt (B), rotate clamp lever (A) 180 degrees. Then start to tighten clamp lever (A).

CHANGING POSITION OF BEVEL CLAMP HANDLE

When the bevel clamp handle does not lock in a conven- ient position, it can be repositioned as follows:

1.DISCONNECT TOOL FROM POWER SOURCE.

2.Loosen bevel clamp handle (A), release bevel index release knob (B), and turn motor (C) to vertical position as shown in Fig. 69. NOTE: IF BLADE GUARD CONTACTS TABLE SURFACE, RAISE TRACK ARM.

3.Loosen bevel clamp handle (A) Fig. 69, several turns, until hex head of screw (D) can be pushed out of hex- shaped recess in yoke.

4.Turn screw (D) Fig. 69, in the desired direction which the handle needs to be turned, one or two flats of the hex head and push it back into

5.Tighten bevel clamp handle (A) Fig. 69. NOTE: Screw is left hand thread - turn clamp handle counterclockwise to tighten.

CHANGING POSITION OF YOKE CLAMP HANDLE

When the yoke clamp handle (A) Fig. 70, does not lock in a convenient position, it can be repositioned as follows:

1.DISCONNECT TOOL FROM POWER SOURCE.

2Remove retaining ring (B) Fig. 70.

3.Reposition yoke clamp handle (A) Fig. 70, on hex clamp nut.

4.Replace retaining ring (B) Fig. 70.

D

![]() B

B

C

Fig. 67

E

![]() A

A  B C

B C

Fig. 68

D

![]() B

B

C

![]() A

A

Fig. 69

A

B![]()

Fig. 70

22