On models with rectangular felt filter:

1.Using a pair of needle nose pliers or a screwdriver pull or pry out the old filter and carefully clean the filter area.

2.Push the new air filter in place. Refer to the "Repair Parts" for the correct part number.

On models with round removable air filter cover:

1.Remove the air filter cover.

2.Remove the air filter from filter cover.

IMPORTANT: Do not operate the compressor with the air filter removed.

3.Place new air filter into filter cover. Refer to the "Repair Parts" for the correct part number.

4.Replace air filter cover and lock into place.

Motor Pulley/Flywheel

Alignment

NOTE: Once the motor pulley has been moved from its factory set location, the grooves of the flywheel and pulley must be aligned to within 1/16" to prevent excessive belt wear.

The air compressor flywheel and motor pulley must be

1.Unplug air compressor from power source.

2.Remove belt guard

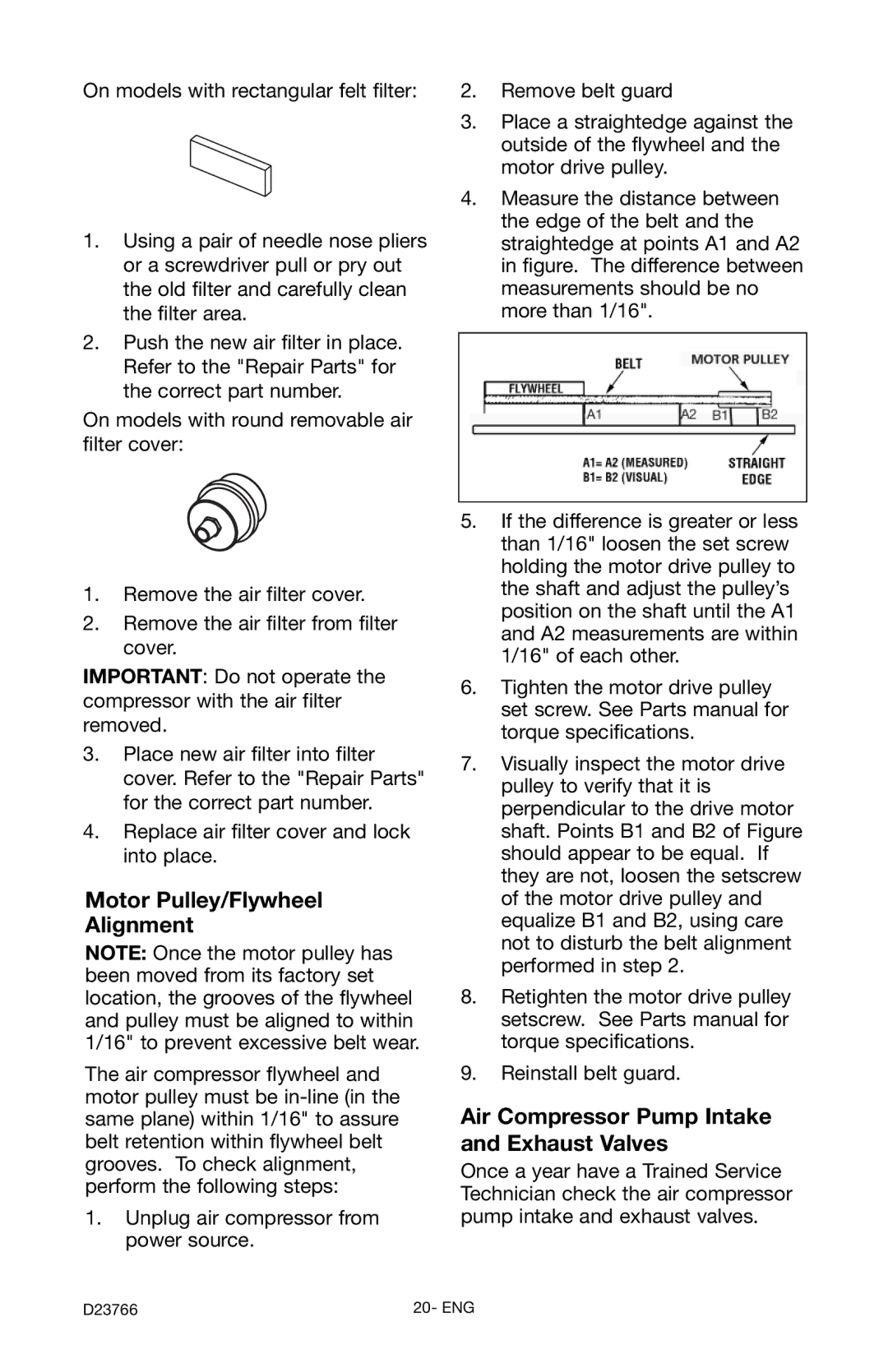

3.Place a straightedge against the outside of the flywheel and the motor drive pulley.

4.Measure the distance between the edge of the belt and the straightedge at points A1 and A2 in figure. The difference between measurements should be no more than 1/16".

5.If the difference is greater or less than 1/16" loosen the set screw holding the motor drive pulley to the shaft and adjust the pulley’s position on the shaft until the A1 and A2 measurements are within 1/16" of each other.

6.Tighten the motor drive pulley set screw. See Parts manual for torque specifications.

7.Visually inspect the motor drive pulley to verify that it is perpendicular to the drive motor shaft. Points B1 and B2 of Figure should appear to be equal. If they are not, loosen the setscrew of the motor drive pulley and equalize B1 and B2, using care not to disturb the belt alignment performed in step 2.

8.Retighten the motor drive pulley setscrew. See Parts manual for torque specifications.

9.Reinstall belt guard.

Air Compressor Pump Intake and Exhaust Valves

Once a year have a Trained Service Technician check the air compressor pump intake and exhaust valves.

D23766 | 20- ENG |