Fitting the splash back

It is essential the splash back is fitted. Remove the two fixing screws (3mm hexagonal socket head) and nuts that pass through the top of the rear flue grille. Hold the splash back in position. From the rear refit the 2 fixing screws and nuts.

Fitting a stability bracket

A stability bracket or chain (not supplied by with the cooker) should be fitted when the cooker is connected to a flexible gas supply.

When fitting a stability bracket read these instructions together with the leaflet supplied with the bracket.

1.Place the cooker in its intended position and level the cooker.

2.Draw a pencil line 100mm from the front edge of the levelling feet.

3.Mark the centre line for the bracket by measuring 550mm from the left hand side of the cooker.

Gas Connection

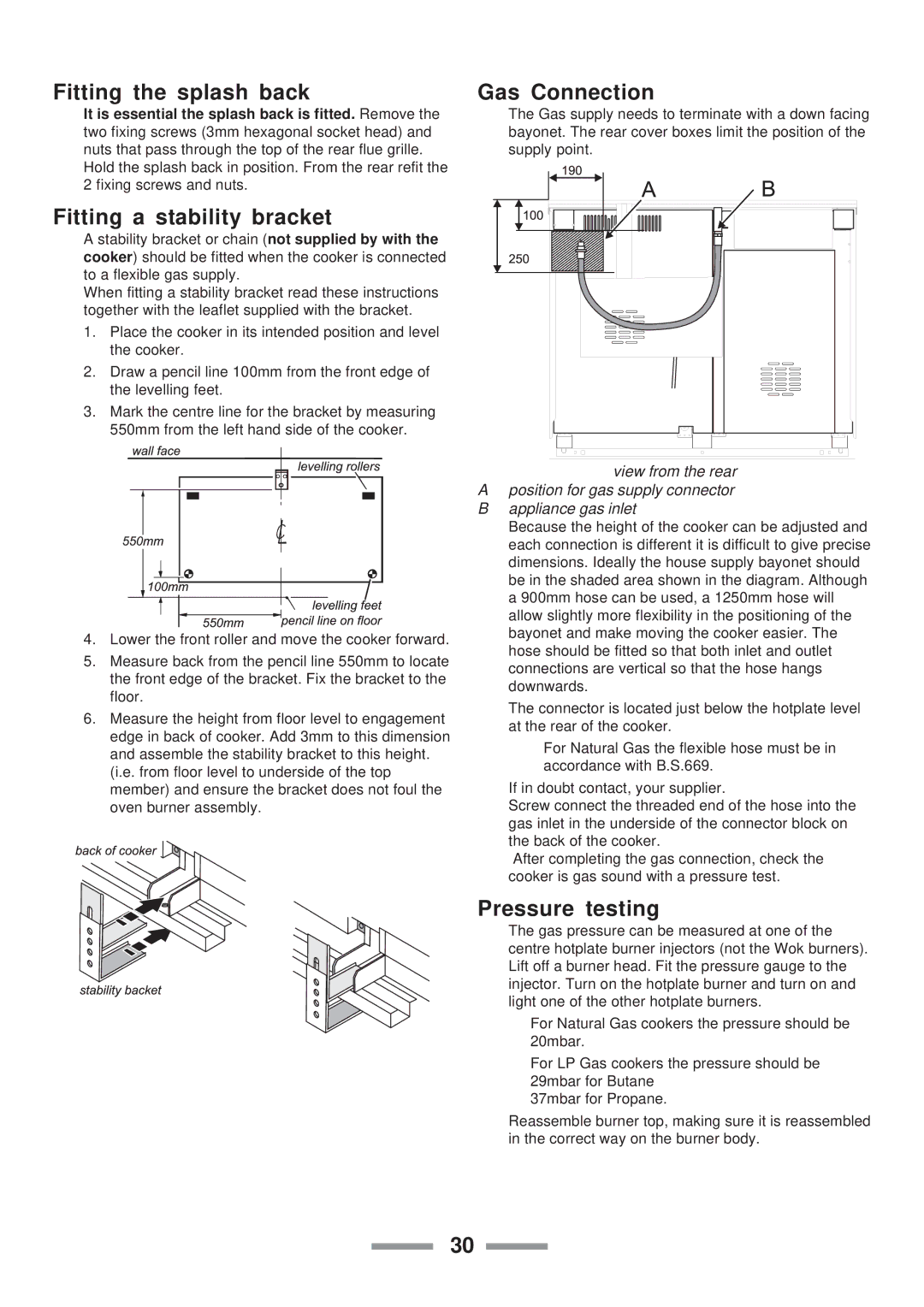

The Gas supply needs to terminate with a down facing bayonet. The rear cover boxes limit the position of the supply point.

4.Lower the front roller and move the cooker forward.

5.Measure back from the pencil line 550mm to locate the front edge of the bracket. Fix the bracket to the floor.

6.Measure the height from floor level to engagement edge in back of cooker. Add 3mm to this dimension and assemble the stability bracket to this height.

(i.e. from floor level to underside of the top member) and ensure the bracket does not foul the oven burner assembly.

view from the rear

Aposition for gas supply connector

Bappliance gas inlet

Because the height of the cooker can be adjusted and each connection is different it is difficult to give precise dimensions. Ideally the house supply bayonet should be in the shaded area shown in the diagram. Although a 900mm hose can be used, a 1250mm hose will allow slightly more flexibility in the positioning of the bayonet and make moving the cooker easier. The hose should be fitted so that both inlet and outlet connections are vertical so that the hose hangs downwards.

The connector is located just below the hotplate level at the rear of the cooker.

For Natural Gas the flexible hose must be in accordance with B.S.669.

If in doubt contact, your supplier.

Screw connect the threaded end of the hose into the gas inlet in the underside of the connector block on the back of the cooker.

After completing the gas connection, check the cooker is gas sound with a pressure test.

Pressure testing

The gas pressure can be measured at one of the centre hotplate burner injectors (not the Wok burners). Lift off a burner head. Fit the pressure gauge to the injector. Turn on the hotplate burner and turn on and light one of the other hotplate burners.

For Natural Gas cookers the pressure should be 20mbar.

For LP Gas cookers the pressure should be 29mbar for Butane

37mbar for Propane.

Reassemble burner top, making sure it is reassembled in the correct way on the burner body.

30