SECTION 1 INSTALLATION

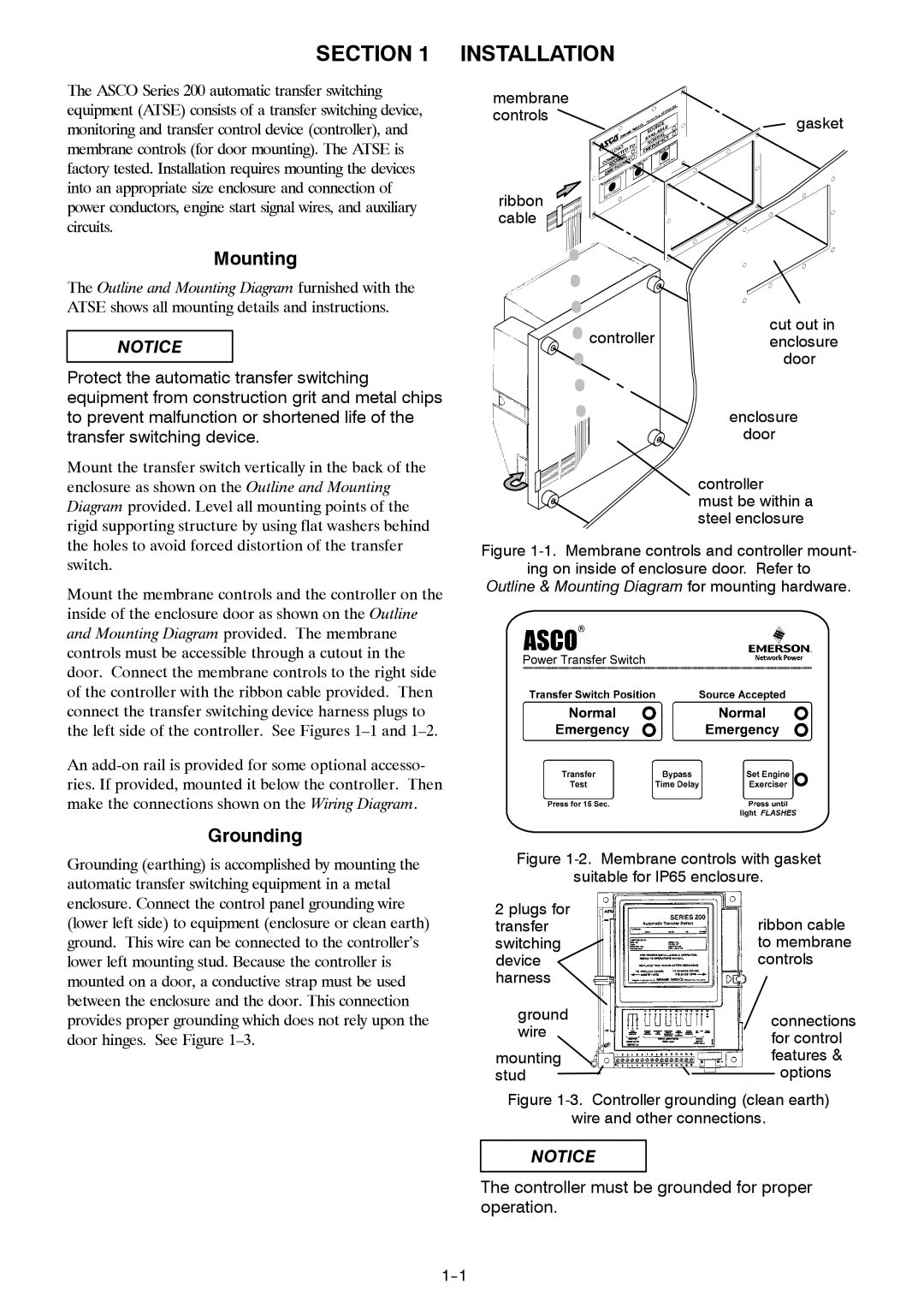

The ASCO Series 200 automatic transfer switching equipment (ATSE) consists of a transfer switching device, monitoring and transfer control device (controller), and membrane controls (for door mounting). The ATSE is factory tested. Installation requires mounting the devices into an appropriate size enclosure and connection of power conductors, engine start signal wires, and auxiliary circuits.

Mounting

The Outline and Mounting Diagram furnished with the ATSE shows all mounting details and instructions.

NOTICE

Protect the automatic transfer switching equipment from construction grit and metal chips to prevent malfunction or shortened life of the transfer switching device.

Mount the transfer switch vertically in the back of the enclosure as shown on the Outline and Mounting Diagram provided. Level all mounting points of the rigid supporting structure by using flat washers behind the holes to avoid forced distortion of the transfer switch.

Mount the membrane controls and the controller on the inside of the enclosure door as shown on the Outline and Mounting Diagram provided. The membrane controls must be accessible through a cutout in the door. Connect the membrane controls to the right side of the controller with the ribbon cable provided. Then connect the transfer switching device harness plugs to the left side of the controller. See Figures

An

Grounding

Grounding (earthing) is accomplished by mounting the automatic transfer switching equipment in a metal enclosure. Connect the control panel grounding wire (lower left side) to equipment (enclosure or clean earth) ground. This wire can be connected to the controller’s lower left mounting stud. Because the controller is mounted on a door, a conductive strap must be used between the enclosure and the door. This connection provides proper grounding which does not rely upon the door hinges. See Figure

membrane |

|

controls | gasket |

|

ribbon cable

cut out in

controllerenclosure door

enclosure door

controller

must be within a steel enclosure

Figure 1-1. Membrane controls and controller mount-

ing on inside of enclosure door. Refer to

Outline & Mounting Diagram for mounting hardware.

Figure 1-2. Membrane controls with gasket

suitable for IP65 enclosure.

2 plugs for | ribbon cable | ||

transfer | |||

switching | to membrane | ||

device | controls | ||

harness |

|

| |

ground | connections | ||

wire | |||

for control | |||

| |||

mounting | features & | ||

stud |

| options | |

| |||

Figure 1-3. Controller grounding (clean earth)

wire and other connections.

NOTICE

The controller must be grounded for proper operation.