INSTALLATION (continued)

Power connections

A Wiring Diagram is furnished with the Series 200 ATSE. All wiring must be made in accordance with the local codes.

Do not run cables in front of the transfer switching device. Conductors can be bundled on the right side of the transfer switching device. Maintain proper electrical clearance between the live metal parts and grounded metal: 13 mm minimum.

It is not necessary to remove the barriers from the transfer switching device to install the conductors. If you do remove them, however, be sure to reinstall the barriers carefully.

Connect main source and load conductors to clearly marked power terminals on the transfer switching device. Be careful when stripping insulation from the conductors; avoid nicking or ringing the conductor. Remove surface oxides from conductors by cleaning with a wire brush. Follow conductor manufacturer’s instructions when aluminum conductor is used. Apply joint compound to conductor, then carefully wipe away excess compound. Tighten the terminals to the torque specified on the label on the transfer switching device.

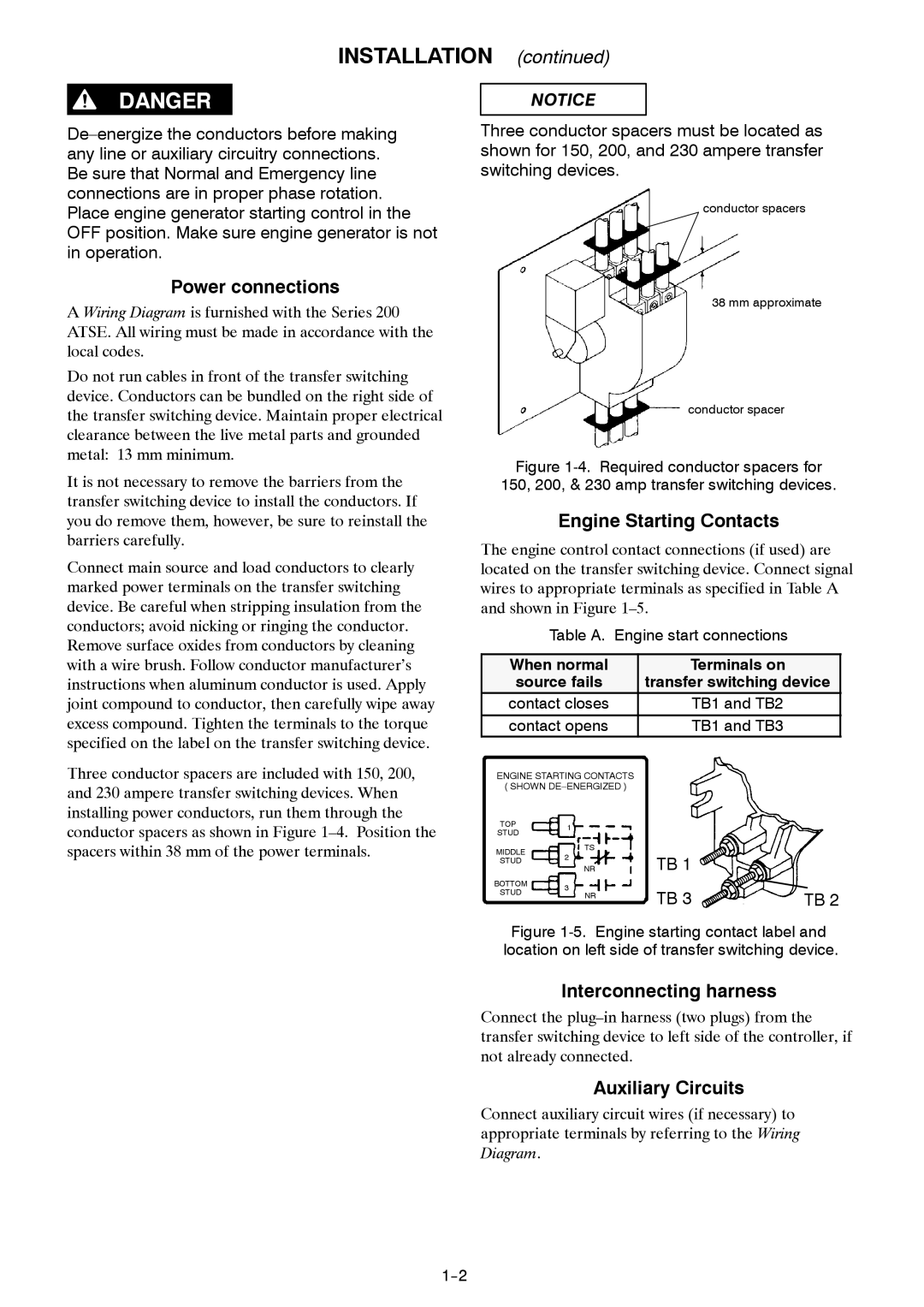

Three conductor spacers are included with 150, 200, and 230 ampere transfer switching devices. When installing power conductors, run them through the conductor spacers as shown in Figure

NOTICE

Three conductor spacers must be located as shown for 150, 200, and 230 ampere transfer switching devices.

conductor spacers

38 mm approximate

conductor spacer

Figure 1-4. Required conductor spacers for 150, 200, & 230 amp transfer switching devices.

Engine Starting Contacts

The engine control contact connections (if used) are located on the transfer switching device. Connect signal wires to appropriate terminals as specified in Table A and shown in Figure

Table A. Engine start connections

When normal | Terminals on |

| ||

source fails | transfer switching device | |||

contact closes | TB1 and TB2 |

| ||

contact opens | TB1 and TB3 |

| ||

ENGINE STARTING CONTACTS |

|

| ||

( SHOWN |

|

| ||

TOP | 1 |

|

| |

STUD |

|

| ||

|

|

| ||

MIDDLE | TS |

|

| |

2 | TB 1 |

| ||

STUD |

| |||

NR |

| |||

BOTTOM | 3 | TB 3 |

| |

STUD | TB 2 | |||

NR | ||||

|

| |||

|

|

| ||

Figure 1-5. Engine starting contact label and location on left side of transfer switching device.

Interconnecting harness

Connect the

Auxiliary Circuits

Connect auxiliary circuit wires (if necessary) to appropriate terminals by referring to the Wiring Diagram.