00809-0400-4728, Rev AA June

Reference Manual

Page

Table of Contents

Appendix a

Specifications Reference Data

Appendix B

TOC-2

Customer Central National Response Center International

Rosemount Temperature Transmitters

Page

Section Introduction

Safety Messages

Explosions could result in death or serious injury

Process leaks could result in death or serious injury

Overview

Manual

Transmitter

Considerations

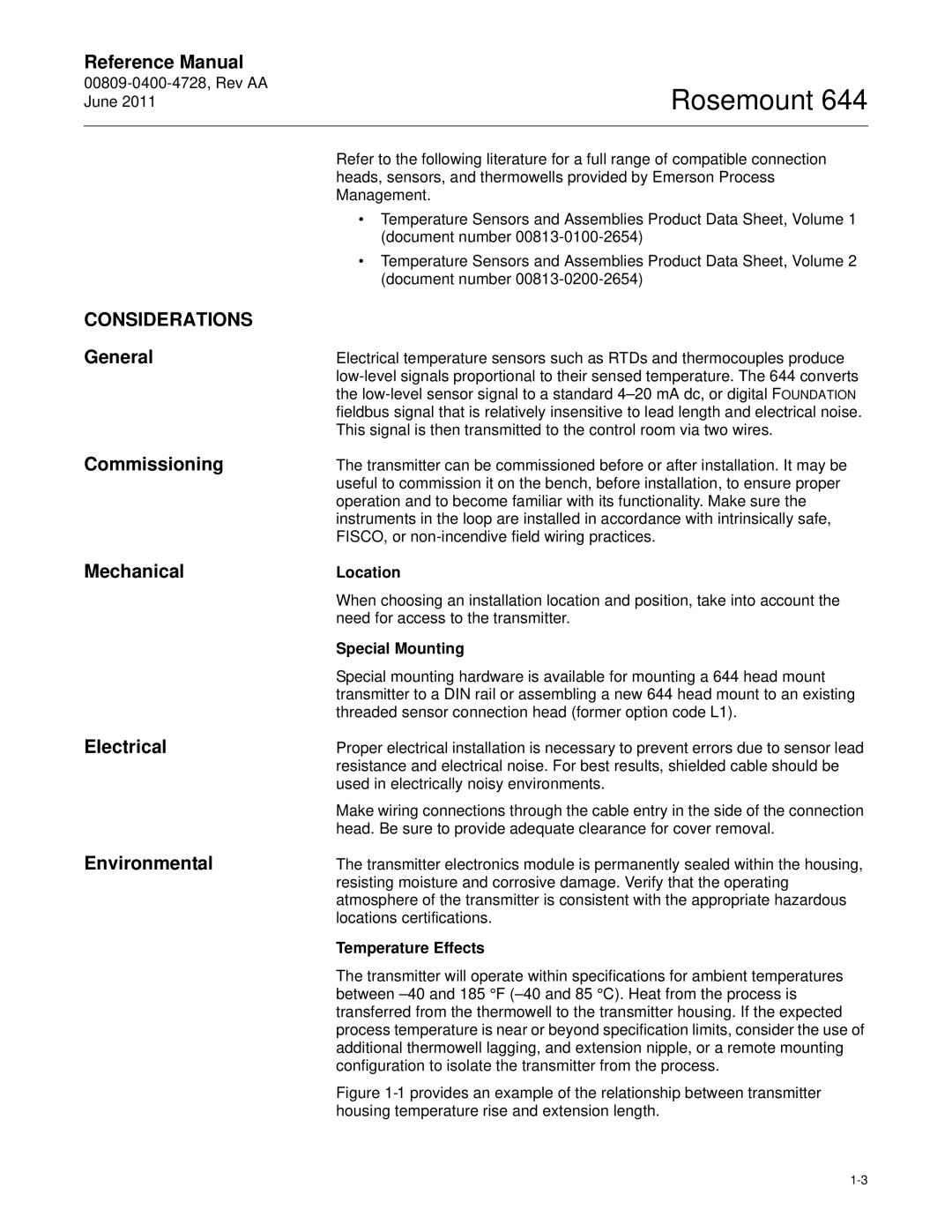

250 C 482 F Oven Temperature 5 6 7 8 Extension Length

22 20 815 C 1500 F Oven Temperature

Example

Above

Section Installation

Within Specifications? Refer to Configuration

Bench Calibration?

Simulate Sensor Input

Mounting

From draining into the transmitter housing

Mounting a 644H to a DIN Rail

Rail asymmetric

Installation

Typical European Installation

Head Mount Transmitter with DIN Plate Style Sensor

Head Mount Transmitter with Threaded Sensor

Typical North American Installation

Installing the LCD Display

LCD Display Installation

Power terminals does not drop below 9 Vdc

Wiring

Thermocouple or Millivolt Inputs

Sensor Connections

Sensor Lead Wire Resistance Effect- RTD Input

Sensor Input Approximate Basic Error

RTD or Ohm Inputs

Error due to amb. temp. var. of ± 25 C

Pt100 2-wire RTD

Foundation fieldbus Installation

Power Supply

Ground the Transmitter

Ungrounded Thermocouple, mV, and RTD/Ohm Inputs

Grounded Thermocouple Inputs

Overview Safety Messages

Section Configuration

Device Description Node Address

General Block Information

Modes

Auto

Resource Transducer Analog Input Other

Link Active Scheduler Block Installation

Foundation Fieldbus Function Blocks

Capabilities

Resource Block

Features

Unicode

Reports

Failedalarms

Featuressel

Maxnotify

PlantWeb Alerts

Failedmask

Maintalarms

Advisory Alarms

Recommended Actions for PlantWeb Alerts

Recommendedaction

Sensor Transducer Block

Configure the AI block

Analog Input AI Function Block

Damping

Pressure Channel Temperature Channel

Ltype

Xdscale and Outscale

Transducer Block

Configuration Examples

Filtering

Process Alarms

Outd

Alarmtype

Displayparamsel

LCD Transducer Block

BLKTYPE#1

PARAMINDEX#1

Overview

Operation and Maintenance

UNITSTYPE#1

CUSTOMUNITS#1

Troubleshooting guide

Troubleshooting Guides

Problems with communications flowchart

Calpointlo + Calminspan

Recall Factory Trim

Diagnostics

Block Blockerr messages

Sensor Transducer Block Xderr messages

Calibrationerr

Description

Status

Manual Mode

Simulation

Simulate

Power Up

Troubleshooting AI block

Symptom Possible Causes Recommended Actions

00809-0400-4728, Rev AA June AI Blockerr Conditions

8lists conditions reported in the Blockerr parameter

Block Errors

10. Resource Block

Condition Name

Self Test Procedure for the LCD

Symptom Possible Causes Recommended Action

Auto

Appendix a Specifications Reference Data

Specifications

FunctionalInputs

Physical

Performance

Rosemount Conformance to Specifications

Foundation Fieldbus Specifications

Function Blocks

2 σ -1 σ

Alarms

Power Supply

Backup Link Active Scheduler LAS

Software Upgrade in the Field

Accuracy

Table A-1. Rosemount 644 Input Options and Accuracy

Accuracy Example

Ambient Temperature Effect

Table A-2. Ambient Temperature Effect

Thermocouples

Temperature Effects Examples

644H DIN a Head Mount

Dimensional Drawings

Mounting

LCD Display

00809-0400-4728, Rev AA

June

Sanitary Housing Covers

LCD Display Cover

Ring 76.2 27.9 74.4 25.4 44.5 70.0

Options

Ordering Information

Alarm Level Configuration Standard

Configuration Standard

Assemble To Options Standard

Enclosure Options Standard

Considerations

Tagging

Transmitter Configuration

Configuration tool

With DeltaV, with AMS, or other Foundation fieldbus host or

Custom Configuration

Standard Foundation fieldbus Configuration

Requirements Option Code Specification

Standard Block Configuration

CE Electromagnetic Compatibility Compliance Testing

Appendix B Product Certifications

Atex Directive 94/9/EC

Hazardous Locations Certificates

North American Certifications

Rosemount 644 with Foundation fieldbus

Fisco Loop/Power Terminals

Loop/Power Terminals

European Certifications

Special Conditions for Safe Use

IECEx Certifications

Temperature Class

To 60 C

Fisco Group IIC To 80 C

Transmitter I.S Transmitter Fisco Sensor

Table B-3. Entity Parameters

Transmitter Sensor

Schedule of Limitations

Pattern Approval for Measuring Instruments See Certificate

Ukraine Gost

Approval Temp

Description Group Code

Installation Drawings

Rosemount

Rosemount

Rosemount

00809-0100-4728, Rev AA June Sheet 2

00809-0100-4728, Rev AA June Sheet 3

00809-0100-4728, Rev AA June

00809-0100-4728, Rev AA June Sheet 2

Rosemount

Rosemount

00809-0100-4728, Rev AA June Sheet 2

00809-0100-4728, Rev AA June Sheet 3

Basic Setup Resource Block

Appendix C Foundation fieldbus Block Information

Definition

Index

Parameters and Descriptions

Features

Failedenable

Featuresel

Maintenable

00809-0400-4728, Rev AA

Sensor Transducer Block

Parameters Descriptions

Description Effects transmitter operation

Primaryvaluetype

Primaryvaluerange

Sensrdetailedstatus

Calvandusencoeff

SESNOR1DAMPING

Xderror

Transducerdirectory

Transducertype

Analog Input AI Function Block

Analog Measurement Access

Outd Cutoff Filter

Convert Calc

Ackoption

AI Parameter Table

Lolopri

LCD Transducer Block

Table C-4. LCD Transducer Block Parameters and Descriptions

Parameter Index Description

PID Block

Table C-5. PID Block Parameters and Descriptions

Parameter Index

Index

Bad Uncertain

Ungrounded Wiring MODEBLK.TARGET

Lolim Lololim Lolopri Lopri Lower Trim Method

DIN Rail Threaded Sensor

Grounded Ungrounded Wiring

Limited Man Mode Unicode UNITSTYPE# Upper Trim Method

Security Self Test

Direct Zero Trim

Index-4

Page

Emerson Process Management Rosemount Inc

Temperature GmbH Pacific Private Limited