GAS HOOK-UP

GAS REQUIREMENTS

Verify the type of gas supplied to the location. The cooktop is shipped from the factory set up and adjusted for Natural Gas or LP (propane), depending on the specific model ordered. Verify that the cooktop is compatible with gas supply at the installation site before proceeding further. Return the cooktop to the dealer if the unit is not set for the gas supplied at the site.

NATURAL GAS

■ Connection: 1/2” NPT Minimum 5/8” dia. flex line. ■ Supply Pressure: 6” to 14” W.C.

LP GAS

■ Connection: 1/2” NPT Minimum 5/8 dia. flex line. ■ Supply Pressure: 11” to 14” W.C.

A regulator is required at the LP source to provide a maximum of 14” W.C. to the cooktop regulator.

HOOK-UP TO GAS SUPPLY

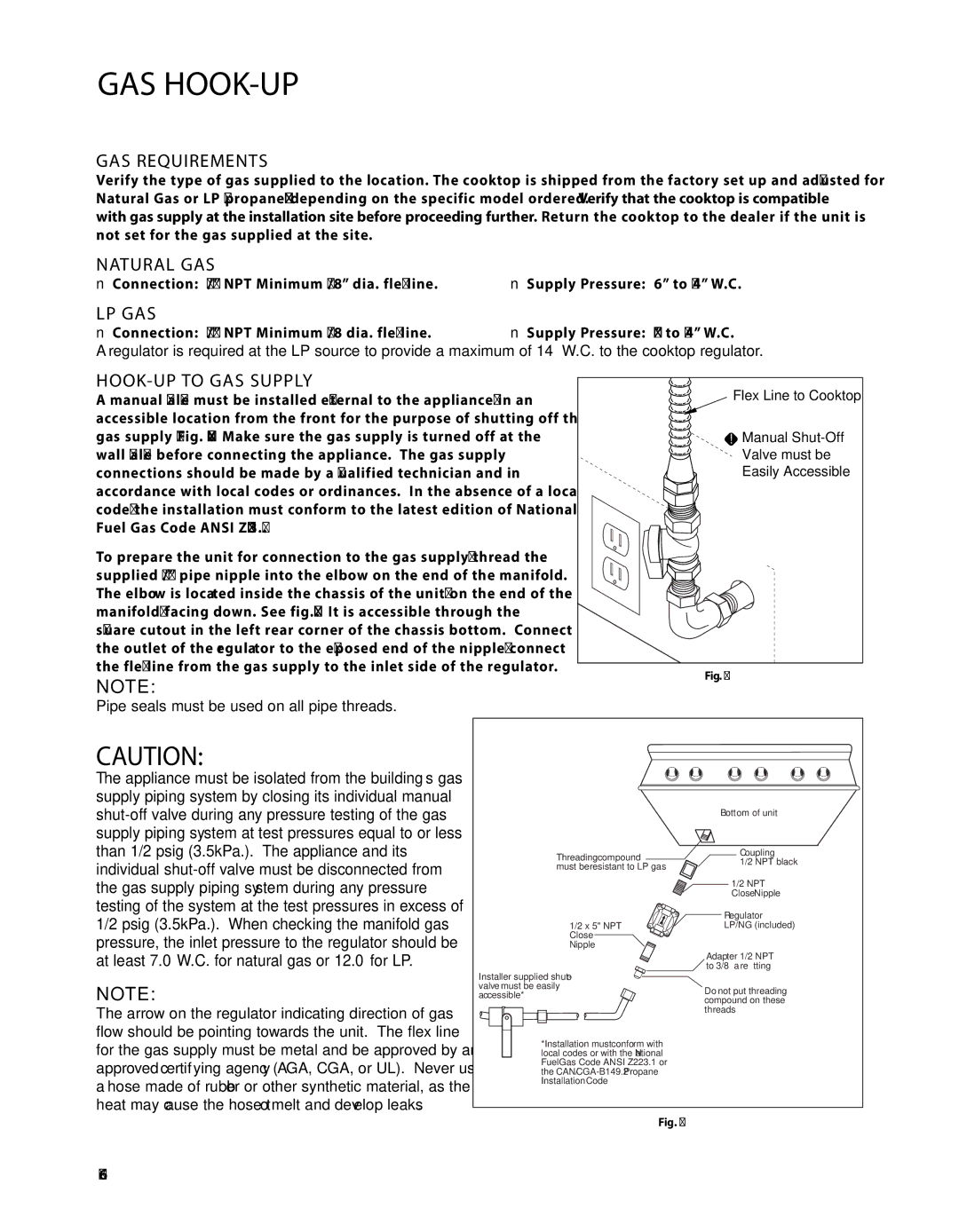

A manual valve must be installed external to the appliance, in an accessible location from the front for the purpose of shutting off the gas supply (Fig. 11). Make sure the gas supply is turned off at the wall valve before connecting the appliance. The gas supply connections should be made by a qualified technician and in accordance with local codes or ordinances. In the absence of a local code, the installation must conform to the latest edition of National Fuel Gas Code ANSI Z223.1.

To prepare the unit for connection to the gas supply, thread the supplied 1/2” pipe nipple into the elbow on the end of the manifold. The elbow is located inside the chassis of the unit, on the end of the manifold, facing down. See fig.12. It is accessible through the square cutout in the left rear corner of the chassis bottom. Connect the outlet of the regulator to the exposed end of the nipple, connect the flex line from the gas supply to the inlet side of the regulator.

NOTE:

Pipe seals must be used on all pipe threads.

Flex Line to Cooktop

!Manual

Fig. 11

CAUTION:

The appliance must be isolated from the building’s gas supply piping system by closing its individual manual

| Bottom of unit | |

Threading compound | Coupling | |

1/2 NPT black | ||

must be resistant to LP gas | ||

| ||

| 1/2 NPT | |

| Close Nipple |

1/2 psig (3.5kPa.). When checking the manifold gas pressure, the inlet pressure to the regulator should be at least 7.0”W.C. for natural gas or 12.0” for LP.

NOTE:

The arrow on the regulator indicating direction of gas flow should be pointing towards the unit. The flex line for the gas supply must be metal and be approved by an approved certifying agency (AGA, CGA, or UL). Never use a hose made of rubber or other synthetic material, as the heat may cause the hose to melt and develop leaks.

1/2 x 5" NPT Close Nipple

Installer supplied

*Installation must conform with local codes or with the National Fuel Gas Code ANSI Z223.1 or the

Regulator LP/NG (included)

Adapter 1/2 NPT to 3/8 flare fitting

Do not put threading compound on these threads

Fig. 12

16