4.Install vent pipe so that it can expand and contract freely as the temperature changes. Support the vent pipe according to applicable codes and vent manufac- turer’s instructions. Pipe support must allow the vent pipe free movement out and back, from side to side, or up and down as necessary, without putting a strain on the heater or vent body. Slope horizontal pipe runs up from the heater at least 1/4” per foot. Install Listed con- densate drains at low points where condensate might collect. Plumb condensate drains to a drain through hard piping or

5.Use Listed firestops for floor and ceiling penetrations. Use Listed thimble for wall penetrations. Use a Listed roof flashing, roof jack, or roof thimble for all roof pen- etrations. Do not fill the space around the vent (that is,

the clear air space in the thimble or firestop) with insulation. The roof opening must be located so that the vent is vertical.

6.Vent Termination – Vertical (See Table 4, Page 13, for height of vent termination above the roof. See Table 7, Page 15, for Listed terminations.) Use a Listed vent ter- minal specified by local and national codes and your manufacturer’s instructions. A roof termination must be vertical.

7.Vent Termination – Horizontal (See Table 7). Use a list- ed wall thimble and vent terminal from Table 7.

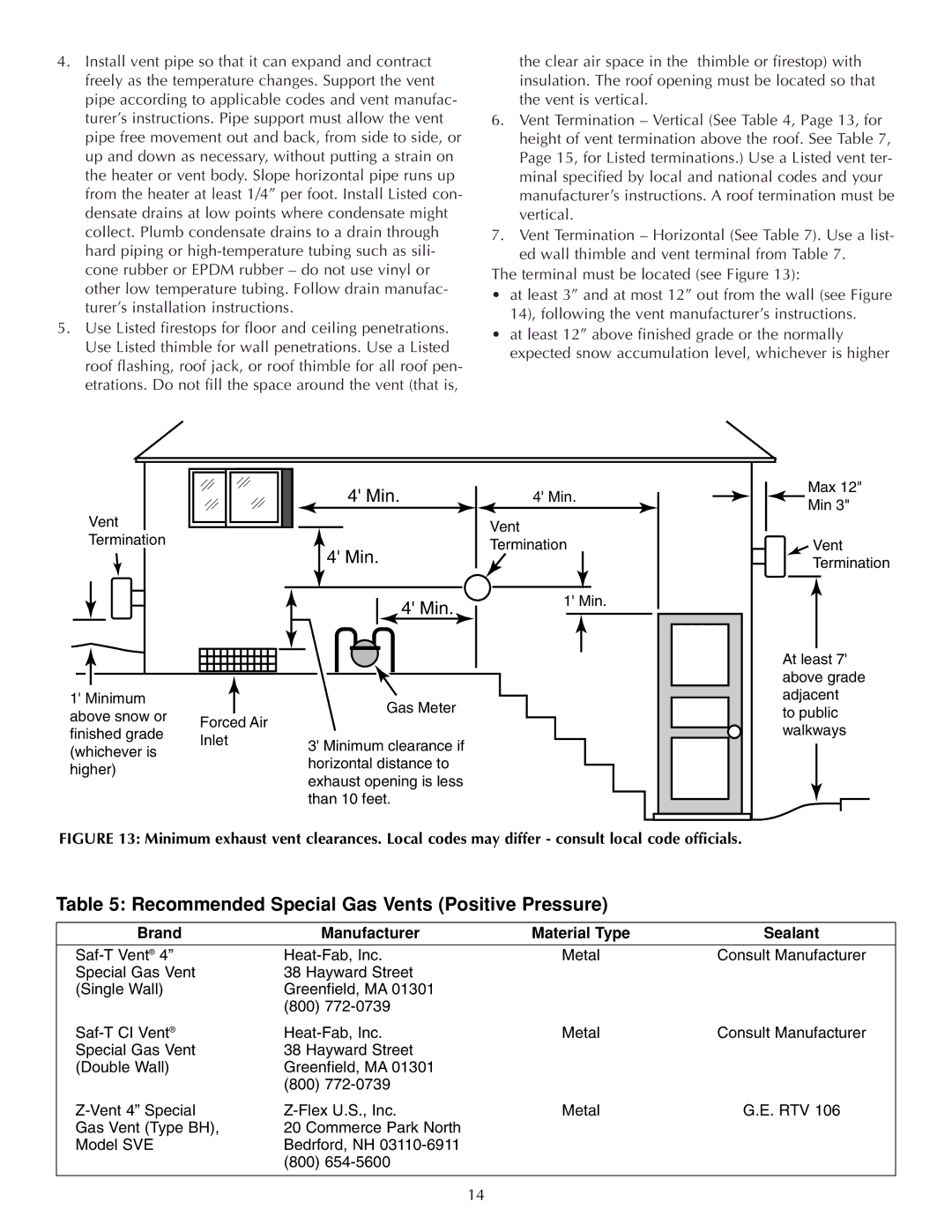

The terminal must be located (see Figure 13):

•at least 3” and at most 12” out from the wall (see Figure 14), following the vent manufacturer’s instructions.

•at least 12” above finished grade or the normally expected snow accumulation level, whichever is higher

Vent Termination

4' Min.

4' Min.

4' Min.

4' Min.

Vent

Termination

1' Min.

Max 12"

Min 3"

![]() Vent Termination

Vent Termination

1' Minimum |

|

| Gas Meter | |

above snow or |

|

| ||

Forced Air |

| |||

finished grade |

| |||

Inlet | 3' Minimum clearance if | |||

(whichever is | ||||

|

| |||

|

| horizontal distance to | ||

higher) |

|

| ||

|

| exhaust opening is less | ||

|

|

| ||

than 10 feet.

At least 7' above grade adjacent

to public walkways

FIGURE 13: Minimum exhaust vent clearances. Local codes may differ - consult local code officials.

Table 5: Recommended Special Gas Vents (Positive Pressure)

Brand | Manufacturer | Material Type | Sealant |

|

|

|

|

Metal | Consult Manufacturer | ||

Special Gas Vent | 38 Hayward Street |

|

|

(Single Wall) | Greenfield, MA 01301 |

|

|

| (800) |

|

|

Metal | Consult Manufacturer | ||

Special Gas Vent | 38 Hayward Street |

|

|

(Double Wall) | Greenfield, MA 01301 |

|

|

| (800) |

|

|

Metal | G.E. RTV 106 | ||

Gas Vent (Type BH), | 20 Commerce Park North |

|

|

Model SVE | Bedrford, NH |

|

|

| (800) |

|

|

|

|

|

|

14