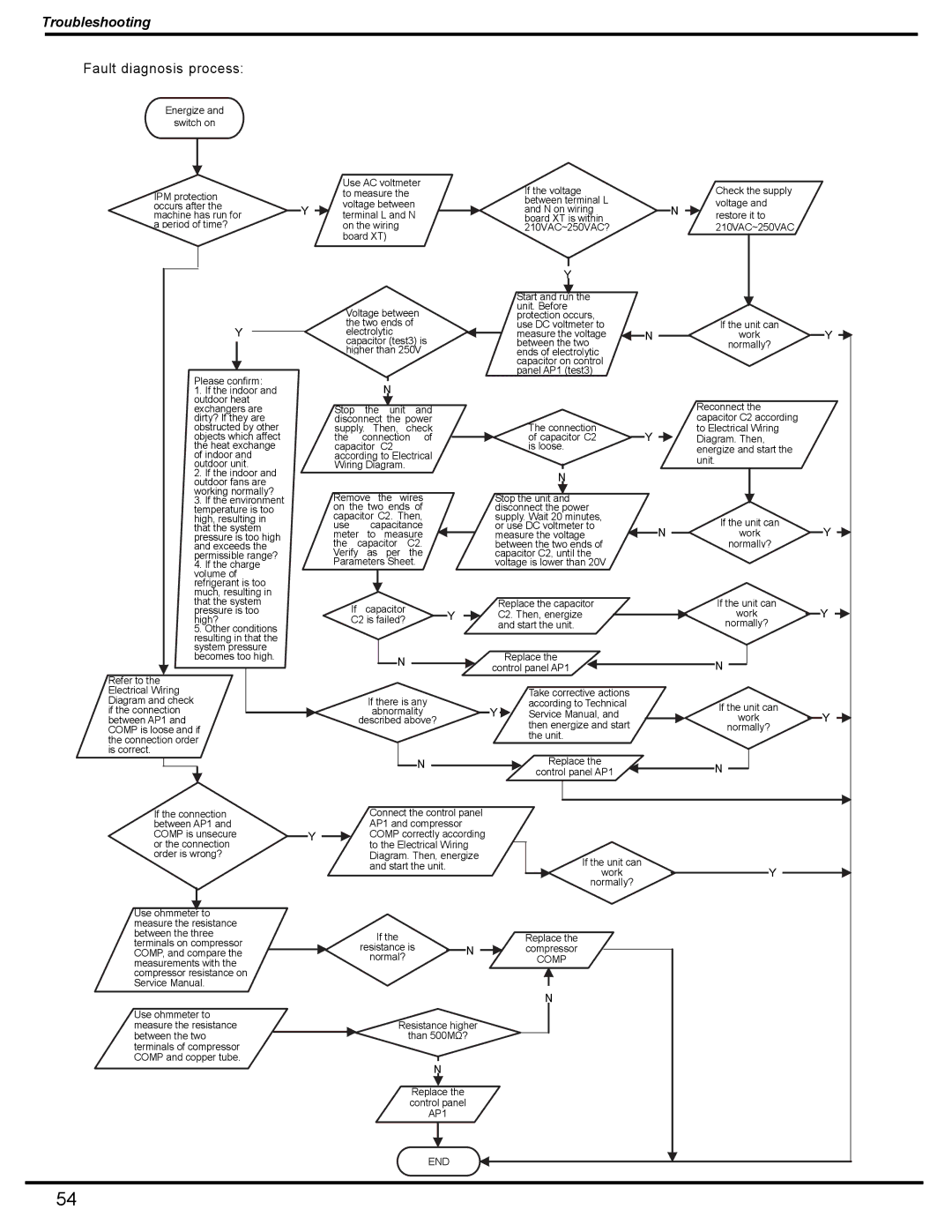

Troubleshooting

Fault diagnosis process:

Energize and

switch on

IPM protection occurs after the machine has run for a period of time?

| Use AC voltmeter | If the voltage |

| Check the supply | |

| to measure the |

| |||

| between terminal L |

|

| ||

| voltage between |

| voltage and | ||

Y | and N on wiring | N | |||

terminal L and N | restore it to | ||||

| board XT is within |

| |||

| on the wiring |

| 210VAC~250VAC | ||

| 210VAC~250VAC? |

|

board XT)

Y

Y

Please confirm:

1. If the indoor and outdoor heat exchangers are dirty? If they are obstructed by other objects which affect the heat exchange of indoor and outdoor unit.

2. If the indoor and outdoor fans are working normally?

|

|

|

|

|

| Start and run the |

|

Voltage between | unit. Before |

| |||||

protection occurs, |

| ||||||

the two ends of |

| use DC voltmeter to |

| ||||

|

| ||||||

electrolytic |

| measure the voltage | N | ||||

capacitor (test3) is | between the two |

| |||||

higher than 250V | ends of electrolytic |

| |||||

|

|

|

|

|

| capacitor on control |

|

|

|

|

|

|

| panel AP1 (test3) |

|

|

|

|

|

|

| ||

|

|

| N |

|

|

|

|

Stop | the |

| unit | and |

|

| |

disconnect the power | The connection |

| |||||

supply. Then, check | Y | ||||||

the | connection | of | of capacitor C2 | ||||

capacitor | C2 |

| is loose. |

| |||

|

| ||||||

according to Electrical |

|

| |||||

Wiring Diagram. |

|

|

| ||||

N

If the unit can

work

normally?

Reconnect the capacitor C2 according to Electrical Wiring Diagram. Then, energize and start the unit.

Y

3. If the environment temperature is too high, resulting in that the system pressure is too high and exceeds the permissible range? 4. If the charge volume of refrigerant is too much, resulting in that the system pressure is too high?

5. Other conditions resulting in that the system pressure becomes too high.

Refer to the Electrical Wiring Diagram and check if the connection between AP1 and COMP is loose and if the connection order is correct.

If the connection between AP1 and COMP is unsecure or the connection order is wrong?

Use ohmmeter to measure the resistance

Remove the wires on the two ends of capacitor C2. Then, use capacitance meter to measure the capacitor C2. Verify as per the Parameters Sheet.

If capacitor | Y | |

C2 is failed? | ||

|

N

If there is any

abnormality

described above?

N

Connect the control panel

AP1 and compressor

YCOMP correctly according to the Electrical Wiring Diagram. Then, energize and start the unit.

Stop the unit and disconnect the power supply. Wait 20 minutes, or use DC voltmeter to

measure the voltageN between the two ends of

capacitor C2, until the voltage is lower than 20V

Replace the capacitor C2. Then, energize and start the unit.

Replace the

control panel AP1

Take corrective actions according to Technical

YService Manual, and then energize and start the unit.

Replace the

control panel AP1

If the unit can

work

normally?

If the unit can

work

normally?

If the unit can

work

normally?

N

If the unit can

work

normally?

N

Y

Y

Y

Y

between the three terminals on compressor COMP, and compare the measurements with the compressor resistance on Service Manual.

Use ohmmeter to measure the resistance between the two terminals of compressor COMP and copper tube.

If the |

| Replace the | |

resistance is | N | compressor | |

normal? | |||

| COMP | ||

|

|

N

Resistance higher than 500M?

N

Replace the control panel AP1

END

54