24G SERIES FLATBOTTOM GAS FRYERS CHAPTER 1: SERVICE PROCEDURES

IMPORTANT

IMPORTANT (Temperature Probe): When installing new temperature probe, ensure probe is positioned properly with the mounting hardware installed (current production systems), or 1/8" from frypot bottom (older systems), prior to tightening the compression nut. Once tightened, the

probe cannot be repositioned.

1.7.2 Removing/Replacing Rocker Switches

In older fryers, ensure probe tip is 1/8" from frypot bottom for proper temperature sensing.

Frypot Bottom

1.Disconnect the fryer from the electrical supply.

2.If switches are located on front panel or control box, remove the screws securing panel. Do not allow the panel to hang on the switch wiring harness; use some type of support.

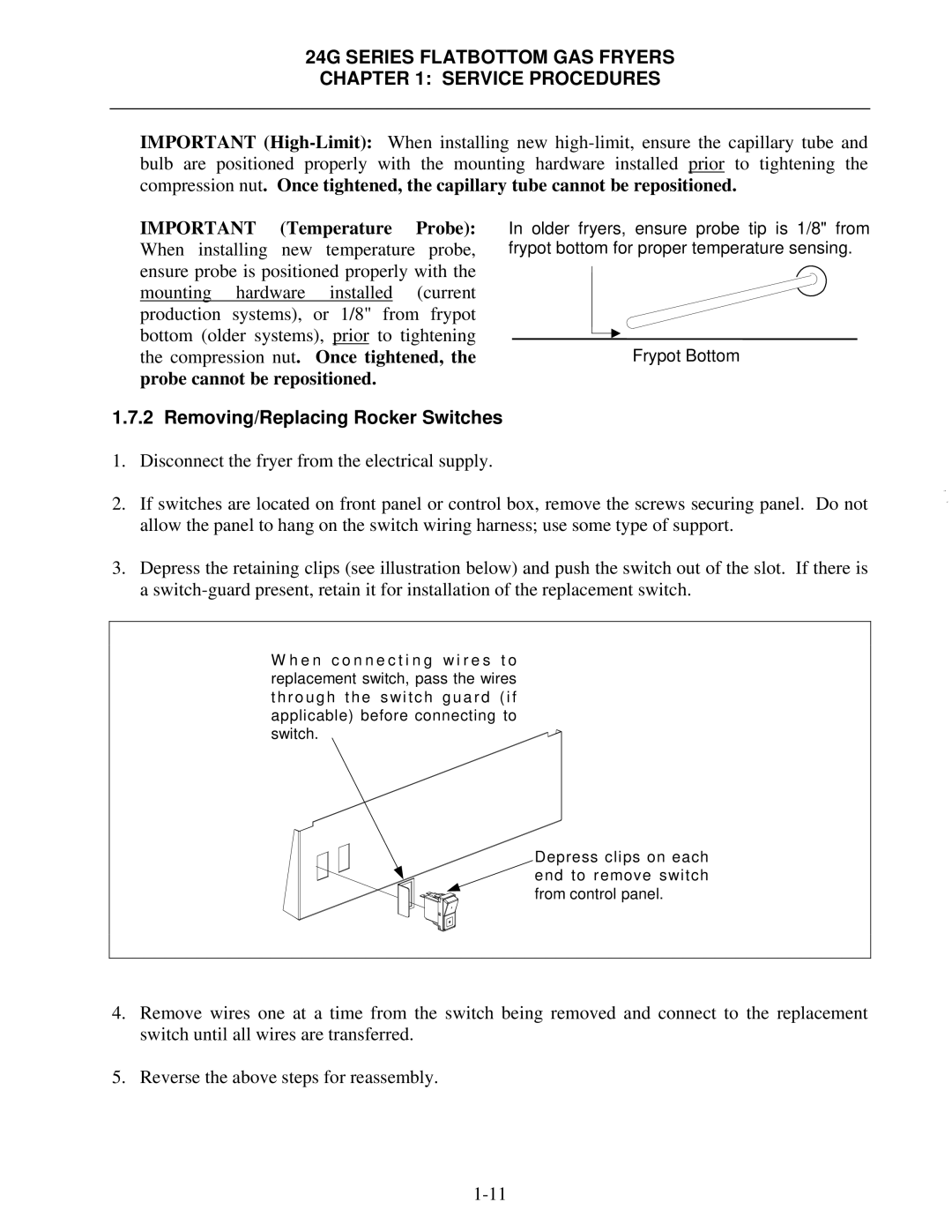

3.Depress the retaining clips (see illustration below) and push the switch out of the slot. If there is a

W h e n c o n n e c t i n g w i r e s t o replacement switch, pass the wires through the swi tch guard (i f applicable) before connecting to switch.

Depress clips on each end to remove switch from control panel.

4.Remove wires one at a time from the switch being removed and connect to the replacement switch until all wires are transferred.

5.Reverse the above steps for reassembly.