24G SERIES FLATBOTTOM GAS FRYERS CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description

24G Series Flatbottom gas fryers contain a welded steel frypot (mild steel) with

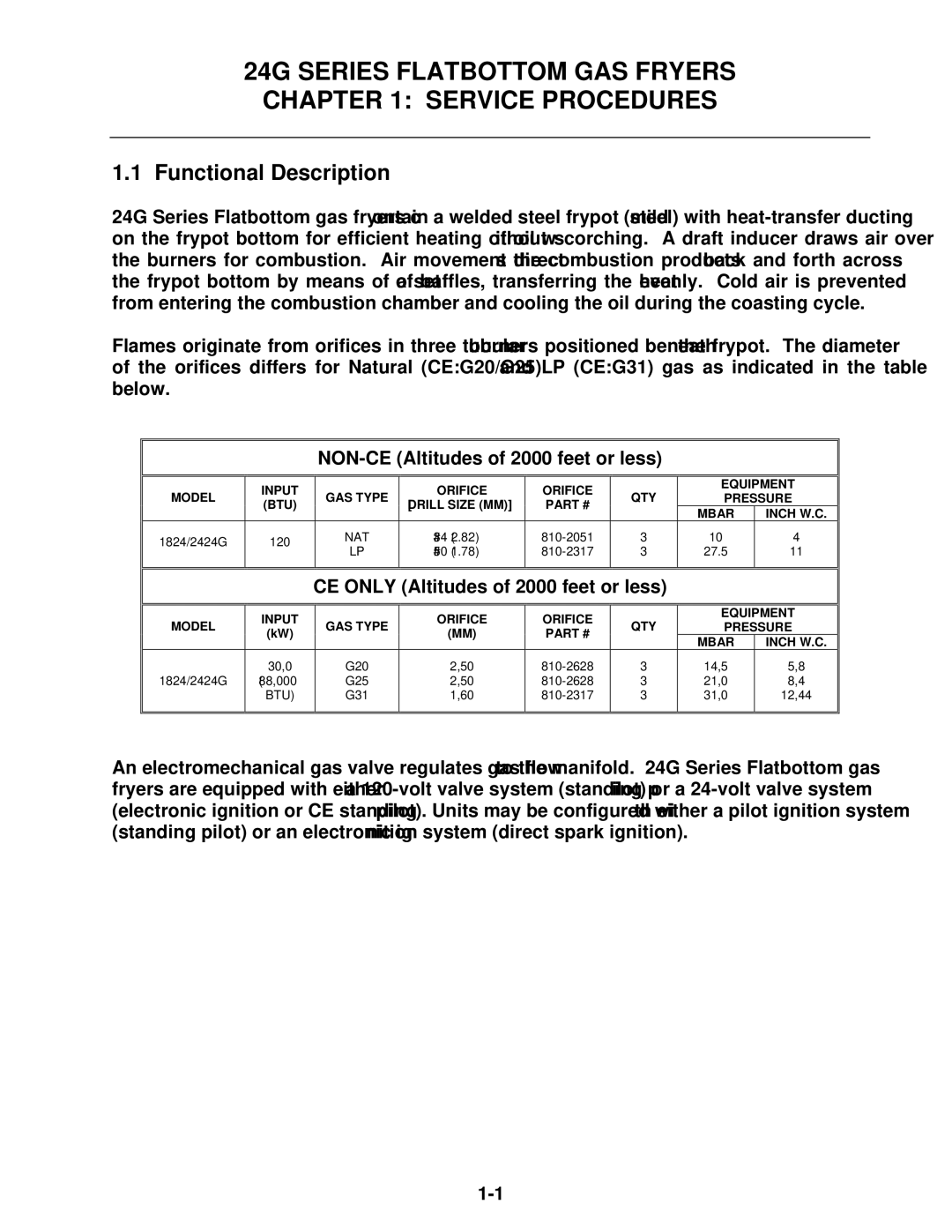

Flames originate from orifices in three tubular burners positioned beneath the frypot. The diameter of the orifices differs for Natural (CE:G20/G25) and LP (CE:G31) gas as indicated in the table below.

NON-CE (Altitudes of 2000 feet or less)

MODEL | INPUT | GAS TYPE | ORIFICE | |

(BTU) | [DRILL SIZE (MM)] | |||

|

| |||

|

|

|

| |

1824/2424G | 120 | NAT | #34 (2.82) | |

LP | #50 (1.78) | |||

|

| |||

|

|

|

|

ORIFICE

PART #

QTY | EQUIPMENT | |

PRESSURE | ||

| MBAR | INCH W.C. |

3 | 10 | 4 |

3 | 27.5 | 11 |

|

|

|

CE ONLY (Altitudes of 2000 feet or less)

MODEL | INPUT | GAS TYPE | ORIFICE | |

(kW) | (MM) | |||

|

| |||

|

|

|

| |

| 30,0 | G20 | 2,50 | |

1824/2424G | (88,000 | G25 | 2,50 | |

| BTU) | G31 | 1,60 | |

|

|

|

|

ORIFICE

PART #

QTY | EQUIPMENT | |

PRESSURE | ||

| MBAR | INCH W.C. |

3 | 14,5 | 5,8 |

3 | 21,0 | 8,4 |

3 | 31,0 | 12,44 |

|

|

|

An electromechanical gas valve regulates gas flow to the manifold. 24G Series Flatbottom gas fryers are equipped with either a