24G SERIES FLATBOTTOM GAS FRYERS CHAPTER 1: SERVICE PROCEDURES

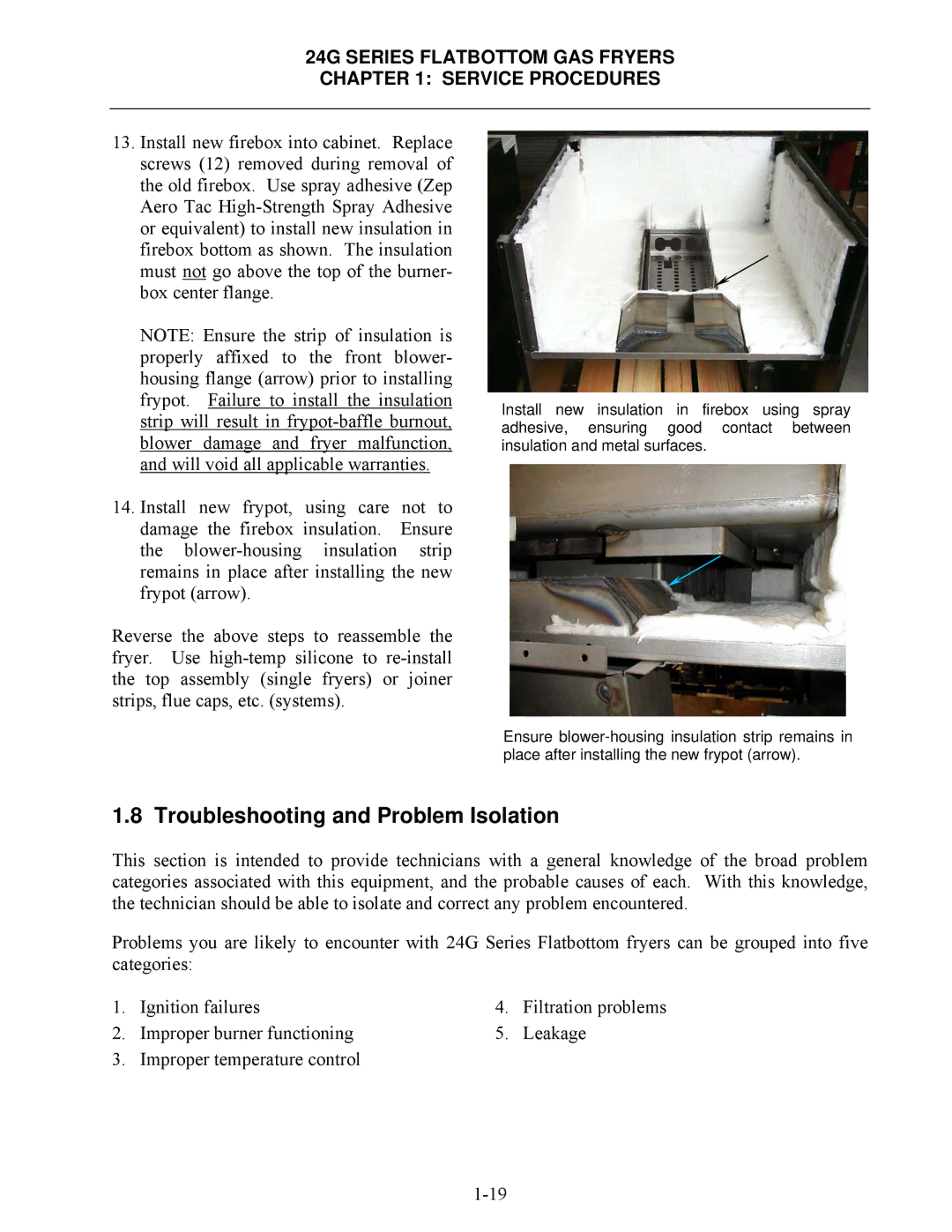

13.Install new firebox into cabinet. Replace screws (12) removed during removal of the old firebox. Use spray adhesive (Zep Aero Tac

NOTE: Ensure the strip of insulation is properly affixed to the front blower- housing flange (arrow) prior to installing frypot. Failure to install the insulation strip will result in

14.Install new frypot, using care not to damage the firebox insulation. Ensure the

Reverse the above steps to reassemble the fryer. Use

Install new insulation in firebox using spray adhesive, ensuring good contact between insulation and metal surfaces.

Ensure

1.8 Troubleshooting and Problem Isolation

This section is intended to provide technicians with a general knowledge of the broad problem categories associated with this equipment, and the probable causes of each. With this knowledge, the technician should be able to isolate and correct any problem encountered.

Problems you are likely to encounter with 24G Series Flatbottom fryers can be grouped into five categories:

1. | Ignition failures | 4. | Filtration problems |

2. | Improper burner functioning | 5. | Leakage |

3. | Improper temperature control |

|

|