24G SERIES FLATBOTTOM GAS FRYERS CHAPTER 1: SERVICE PROCEDURES

A pump seized by debris or hard shortening must be disassembled, cleaned and reassembled as follows:

1.Disconnect power to the filter system.

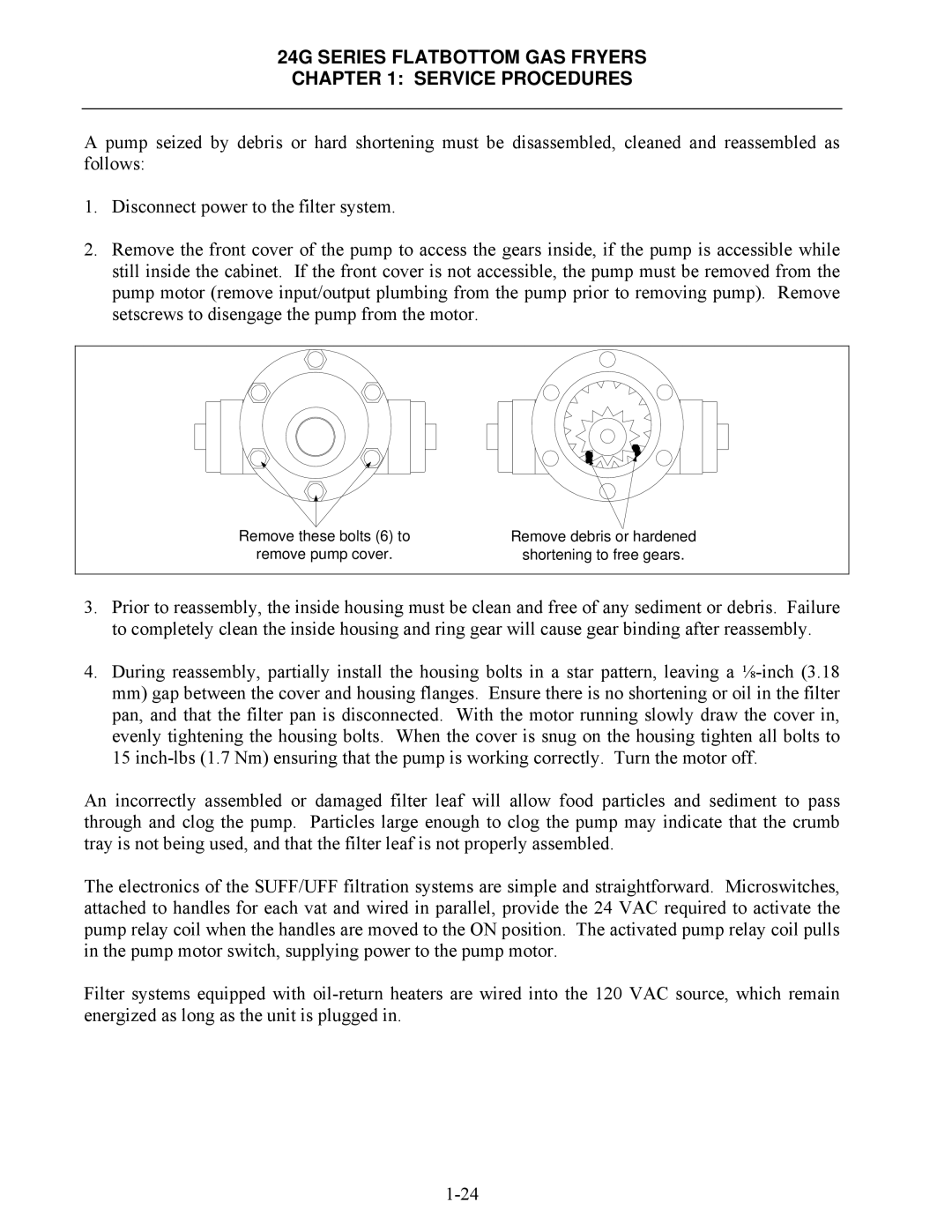

2.Remove the front cover of the pump to access the gears inside, if the pump is accessible while still inside the cabinet. If the front cover is not accessible, the pump must be removed from the pump motor (remove input/output plumbing from the pump prior to removing pump). Remove setscrews to disengage the pump from the motor.

|

|

|

|

|

|

Remove these bolts (6) to | Remove debris or hardened | |

remove pump cover. | shortening to free gears. | |

|

|

|

3.Prior to reassembly, the inside housing must be clean and free of any sediment or debris. Failure to completely clean the inside housing and ring gear will cause gear binding after reassembly.

4.During reassembly, partially install the housing bolts in a star pattern, leaving a

An incorrectly assembled or damaged filter leaf will allow food particles and sediment to pass through and clog the pump. Particles large enough to clog the pump may indicate that the crumb tray is not being used, and that the filter leaf is not properly assembled.

The electronics of the SUFF/UFF filtration systems are simple and straightforward. Microswitches, attached to handles for each vat and wired in parallel, provide the 24 VAC required to activate the pump relay coil when the handles are moved to the ON position. The activated pump relay coil pulls in the pump motor switch, supplying power to the pump motor.

Filter systems equipped with