Hole for | BOW |

stuffing tube |

|

Upper Half

Lower Half

Saw along slope of hull.

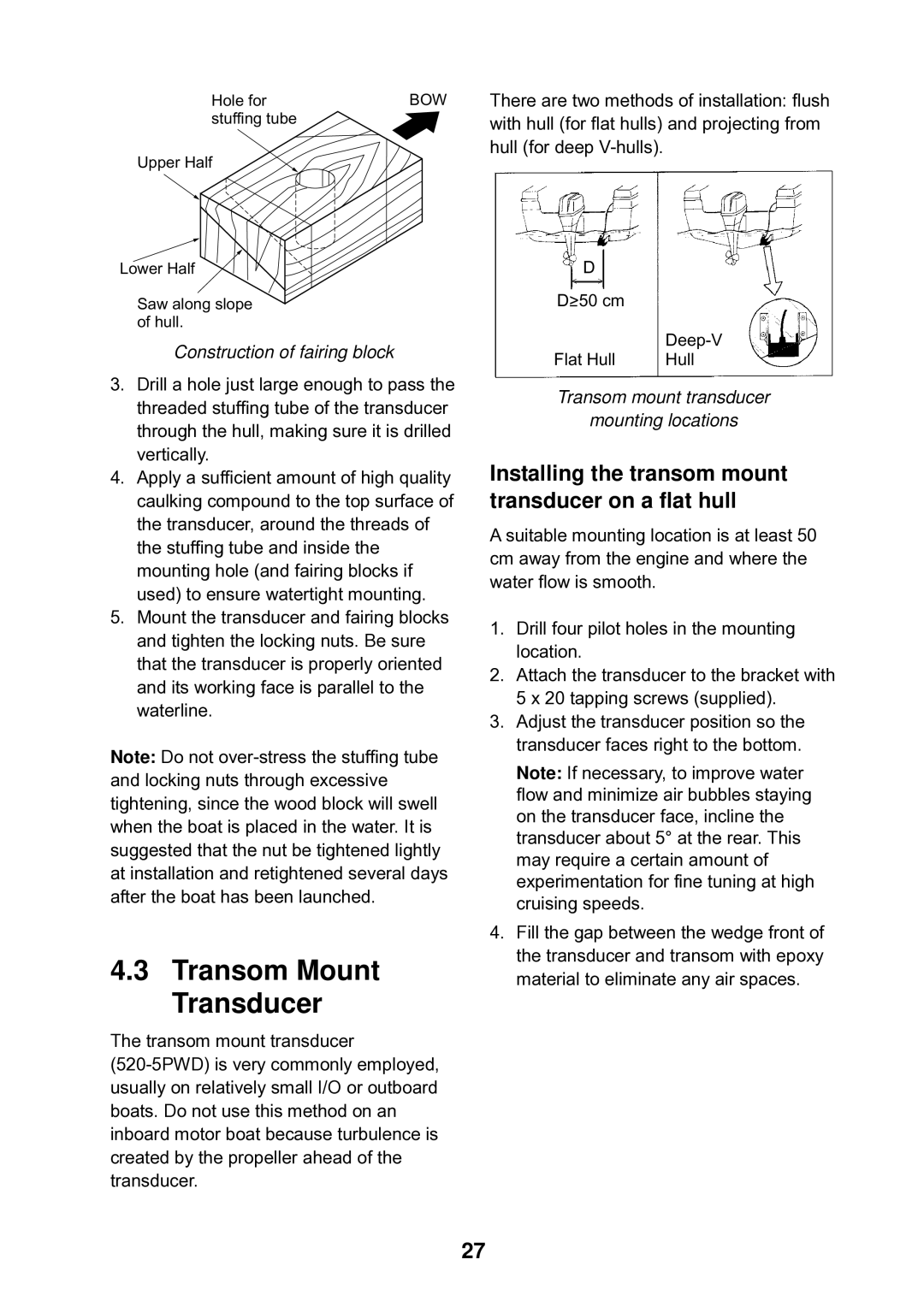

Construction of fairing block

3.Drill a hole just large enough to pass the threaded stuffing tube of the transducer through the hull, making sure it is drilled vertically.

4.Apply a sufficient amount of high quality caulking compound to the top surface of the transducer, around the threads of the stuffing tube and inside the mounting hole (and fairing blocks if used) to ensure watertight mounting.

5.Mount the transducer and fairing blocks and tighten the locking nuts. Be sure that the transducer is properly oriented and its working face is parallel to the waterline.

Note: Do not

4.3Transom Mount Transducer

The transom mount transducer

There are two methods of installation: flush with hull (for flat hulls) and projecting from hull (for deep

|

|

| D |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

D>50 cm |

| ||||

|

|

|

|

| |

Flat Hull | Hull | ||||

Transom mount transducer

mounting locations

Installing the transom mount transducer on a flat hull

A suitable mounting location is at least 50 cm away from the engine and where the water flow is smooth.

1.Drill four pilot holes in the mounting location.

2.Attach the transducer to the bracket with 5 x 20 tapping screws (supplied).

3.Adjust the transducer position so the transducer faces right to the bottom.

Note: If necessary, to improve water flow and minimize air bubbles staying on the transducer face, incline the transducer about 5° at the rear. This may require a certain amount of experimentation for fine tuning at high cruising speeds.

4.Fill the gap between the wedge front of the transducer and transom with epoxy material to eliminate any air spaces.

27