Initial Startup

Do not operate Reactor without all covers and shrouds in place.

Fluid Temperature Sensor (FTS) Calibration

Calibrate the FTS ONLY at initial startup (the first ![]()

![]() time the unit is operated) and any time the hose length changes.

time the unit is operated) and any time the hose length changes.

1.Before turning on the unit, ensure all hoses and cables are properly connected. To ensure that the FTS in the hose is at the same temperature as the heaters, keep heat off and store the hose FTS near the machine for several minutes.

2.While holding down the temperature unit button (Fahrenheit - “F” or Celsius - “C”) turn the Reactor main power ON.

3.Hold the temperature unit button until temperature is shown on the display. The fluid temperature sensor is now correctly calibrated.

Initial Startup

3.Turn both PRESSURE RELIEF/SPRAY valves (SA, SB) to SPRAY.

SB

SA

ti8442a

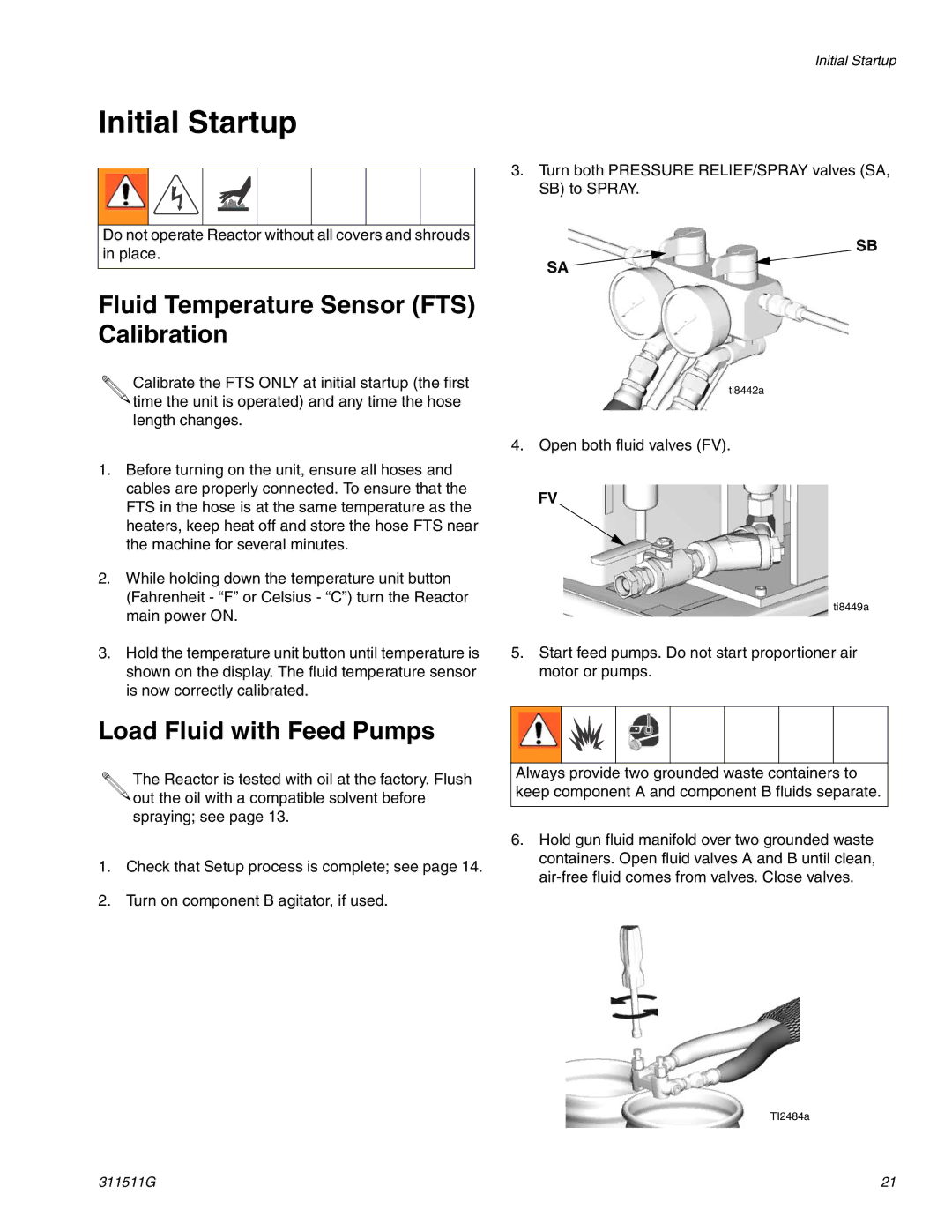

4.Open both fluid valves (FV).

FV

ti8449a

5.Start feed pumps. Do not start proportioner air motor or pumps.

Load Fluid with Feed Pumps

The Reactor is tested with oil at the factory. Flush ![]()

![]() out the oil with a compatible solvent before spraying; see page 13.

out the oil with a compatible solvent before spraying; see page 13.

1.Check that Setup process is complete; see page 14.

2.Turn on component B agitator, if used.

Always provide two grounded waste containers to keep component A and component B fluids separate.

6.Hold gun fluid manifold over two grounded waste containers. Open fluid valves A and B until clean,

TI2484a

311511G | 21 |