Pressure Relief

Procedure

1.Turn off feed pumps and agitator if used.

2.Turn PARK/RUN switch to PARK.

3.Trigger gun to relieve pressure.

4.Turn off air inlet valve.

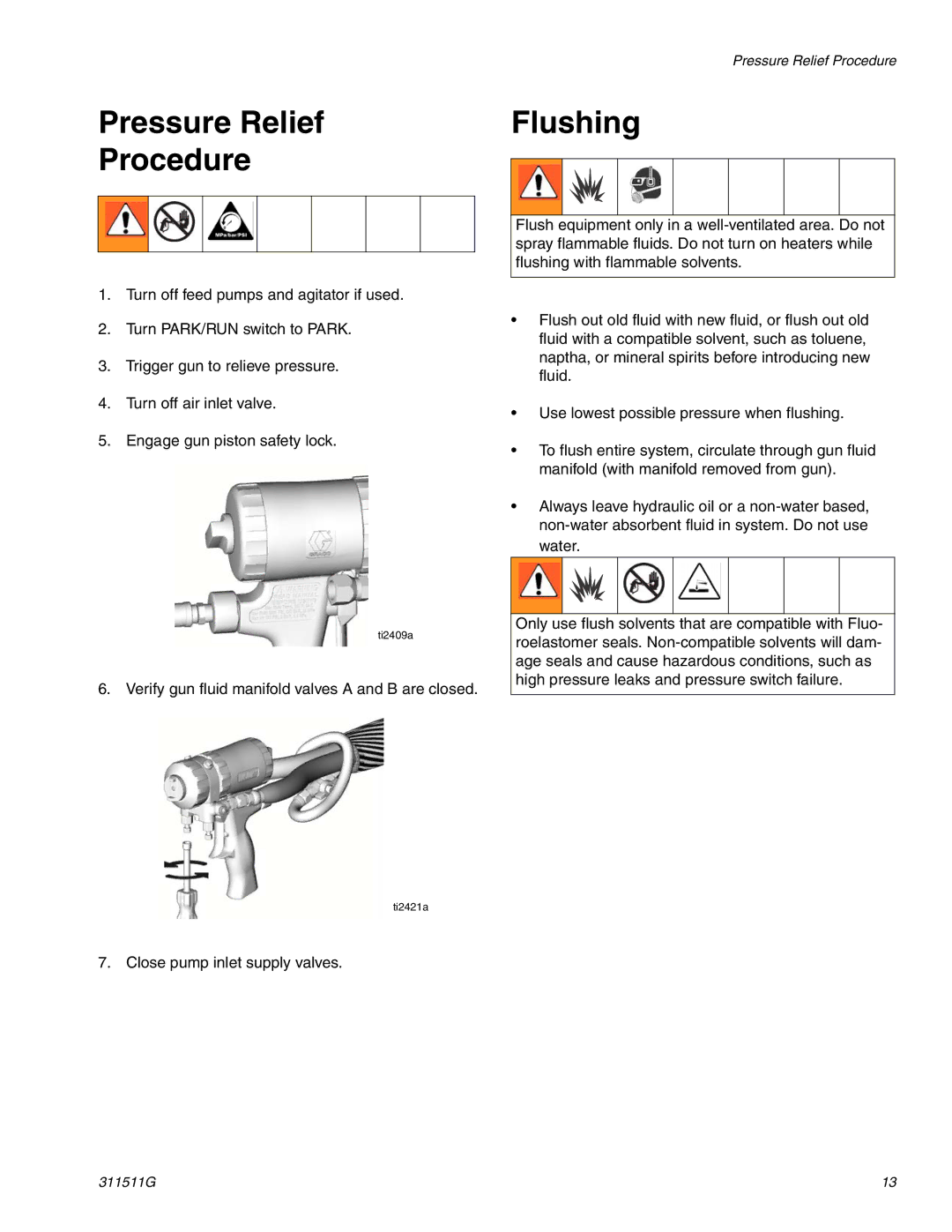

5.Engage gun piston safety lock.

ti2409a

6. Verify gun fluid manifold valves A and B are closed.

ti2421a

7. Close pump inlet supply valves.

Pressure Relief Procedure

Flushing

Flush equipment only in a

•Flush out old fluid with new fluid, or flush out old fluid with a compatible solvent, such as toluene, naptha, or mineral spirits before introducing new fluid.

•Use lowest possible pressure when flushing.

•To flush entire system, circulate through gun fluid manifold (with manifold removed from gun).

•Always leave hydraulic oil or a

Only use flush solvents that are compatible with Fluo- roelastomer seals.

311511G | 13 |