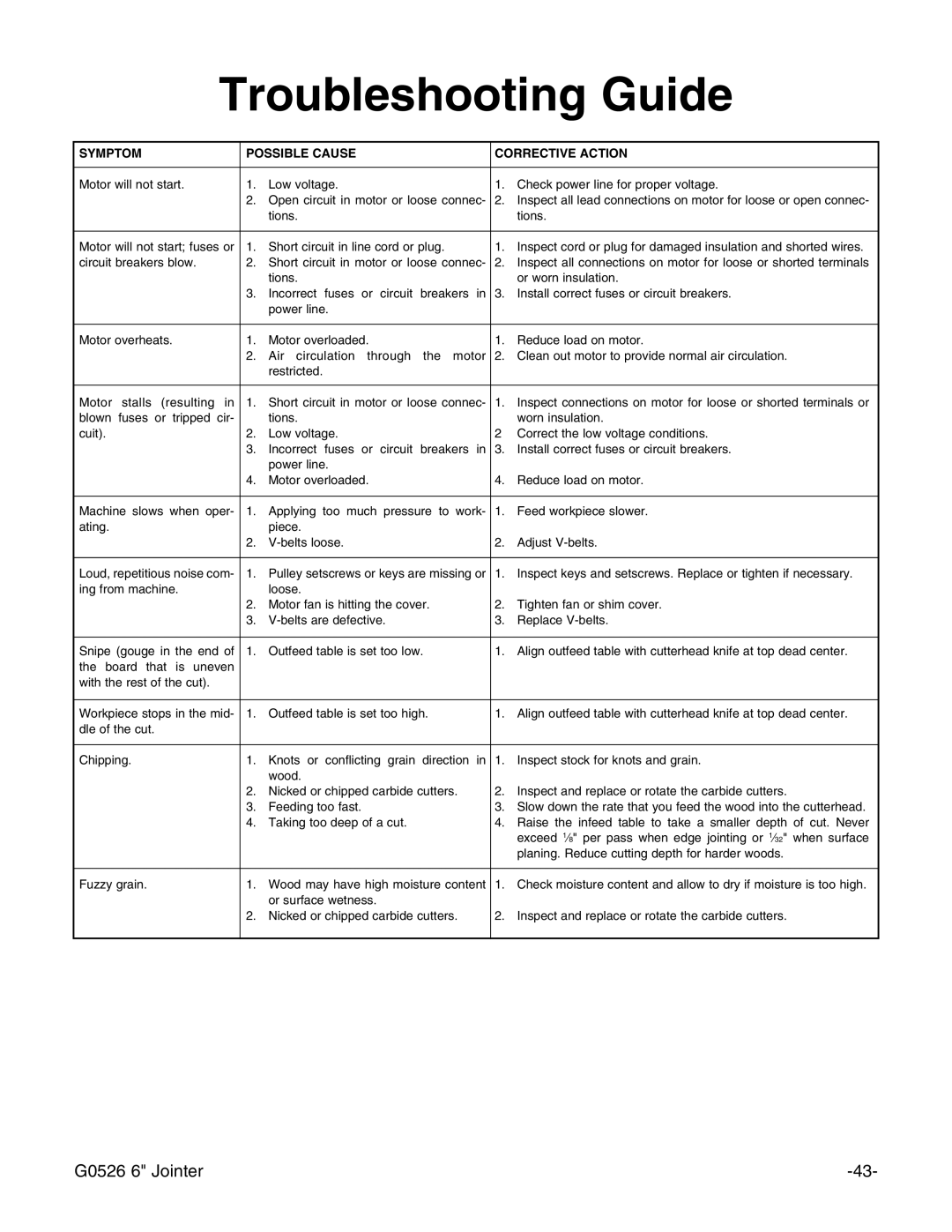

Troubleshooting Guide

SYMPTOM | POSSIBLE CAUSE | CORRECTIVE ACTION | ||

|

|

|

|

|

Motor will not start. | 1. | Low voltage. | 1. | Check power line for proper voltage. |

| 2. | Open circuit in motor or loose connec- | 2. | Inspect all lead connections on motor for loose or open connec- |

|

| tions. |

| tions. |

|

|

|

|

|

Motor will not start; fuses or | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and shorted wires. |

circuit breakers blow. | 2. | Short circuit in motor or loose connec- | 2. | Inspect all connections on motor for loose or shorted terminals |

|

| tions. |

| or worn insulation. |

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. |

|

| power line. |

|

|

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

| restricted. |

|

|

|

|

|

|

|

Motor stalls (resulting in | 1. | Short circuit in motor or loose connec- | 1. | Inspect connections on motor for loose or shorted terminals or |

blown fuses or tripped cir- |

| tions. |

| worn insulation. |

cuit). | 2. | Low voltage. | 2 | Correct the low voltage conditions. |

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. |

|

| power line. |

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. |

|

|

|

|

|

Machine slows when oper- | 1. | Applying too much pressure to work- | 1. | Feed workpiece slower. |

ating. |

| piece. |

|

|

| 2. | 2. | Adjust | |

|

|

|

|

|

Loud, repetitious noise com- | 1. | Pulley setscrews or keys are missing or | 1. | Inspect keys and setscrews. Replace or tighten if necessary. |

ing from machine. |

| loose. |

|

|

| 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover. |

| 3. | 3. | Replace | |

|

|

|

|

|

Snipe (gouge in the end of | 1. | Outfeed table is set too low. | 1. | Align outfeed table with cutterhead knife at top dead center. |

the board that is uneven |

|

|

|

|

with the rest of the cut). |

|

|

|

|

|

|

|

|

|

Workpiece stops in the mid- | 1. | Outfeed table is set too high. | 1. | Align outfeed table with cutterhead knife at top dead center. |

dle of the cut. |

|

|

|

|

|

|

|

|

|

Chipping. | 1. | Knots or conflicting grain direction in | 1. | Inspect stock for knots and grain. |

|

| wood. |

|

|

| 2. | Nicked or chipped carbide cutters. | 2. | Inspect and replace or rotate the carbide cutters. |

| 3. | Feeding too fast. | 3. | Slow down the rate that you feed the wood into the cutterhead. |

| 4. | Taking too deep of a cut. | 4. | Raise the infeed table to take a smaller depth of cut. Never |

|

|

|

| exceed 1Ú8" per pass when edge jointing or 1Ú32" when surface |

|

|

|

| planing. Reduce cutting depth for harder woods. |

|

|

|

|

|

Fuzzy grain. | 1. | Wood may have high moisture content | 1. | Check moisture content and allow to dry if moisture is too high. |

|

| or surface wetness. |

|

|

| 2. | Nicked or chipped carbide cutters. | 2. | Inspect and replace or rotate the carbide cutters. |

|

|

|

|

|

G0526 6" Jointer |