Blade Alignment

If the blade contacts the table insert when raised or tilted, the blade must be aligned by moving the table.

Tools Needed | Qty |

Wrench 14mm | ................................................... 1 |

To adjust the blade by moving the table:

1.DISCONNECT THE SAW FROM POWER!

2.Loosen the three table mounting bolts (Page 51) and adjust the table until the blade does not contact the insert. Tighten all the mount- ing bolts.

3.Make sure the blade does not contact the table insert when raised or tilted. Recheck parallelism of the blade to the miter slot (see Page 51). Adjust as necessary until the blade does not touch the insert.

Adjusting Fence

The rip fence included with your Model G0605X/ G0606X Table Saw is designed to provide excel- lent ripping accuracy when properly adjusted. There are three main adjustments to concern yourself with: square, parallelism and clamping pressure.

Tools Needed | Qty |

Hex Wrench 4mm | .............................................. 1 |

Hex Wrench 6mm | .............................................. 1 |

Machinist Square | 1 |

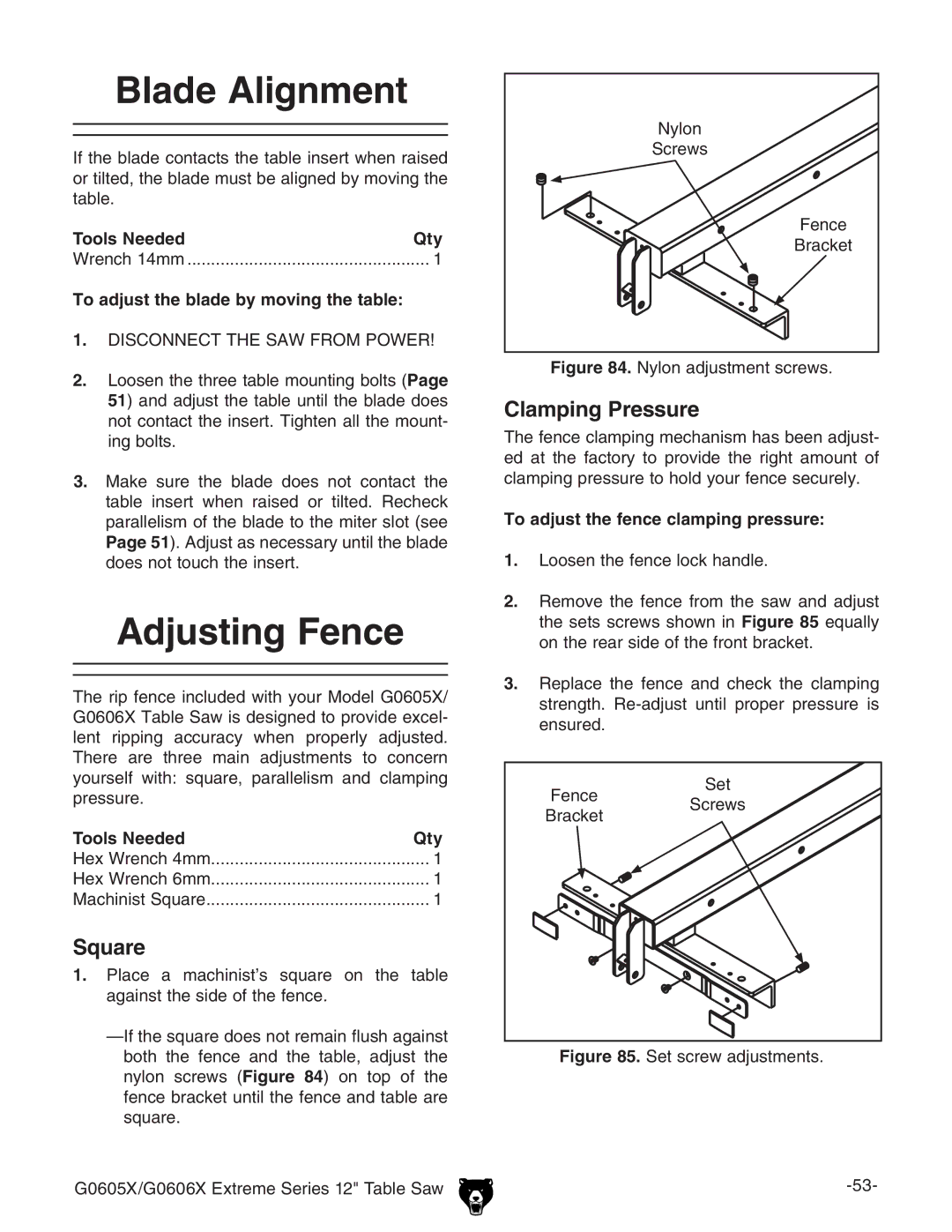

Square

1.Place a machinist’s square on the table against the side of the fence.

Nylon

Screws

Fence

Bracket

Figure 84. Nylon adjustment screws.

Clamping Pressure

The fence clamping mechanism has been adjust- ed at the factory to provide the right amount of clamping pressure to hold your fence securely.

To adjust the fence clamping pressure:

1.Loosen the fence lock handle.

2.Remove the fence from the saw and adjust the sets screws shown in Figure 85 equally on the rear side of the front bracket.

3.Replace the fence and check the clamping strength.

Fence | Set | |

Screws | ||

Bracket | ||

|

Figure 85. Set screw adjustments.

G0605X/G0606X Extreme Series 12" Table Saw |