Edge Jointing

The purpose of edge jointing is to produce a fin- ished,

NOTICE

If you are not experienced with a jointer, set the depth of cut to 0", and practice feeding the workpiece across the tables as described below. This procedure will better prepare you for the actual operation.

Figure 24. Typical edge jointing operation.

Portion

Removed with

Jointer

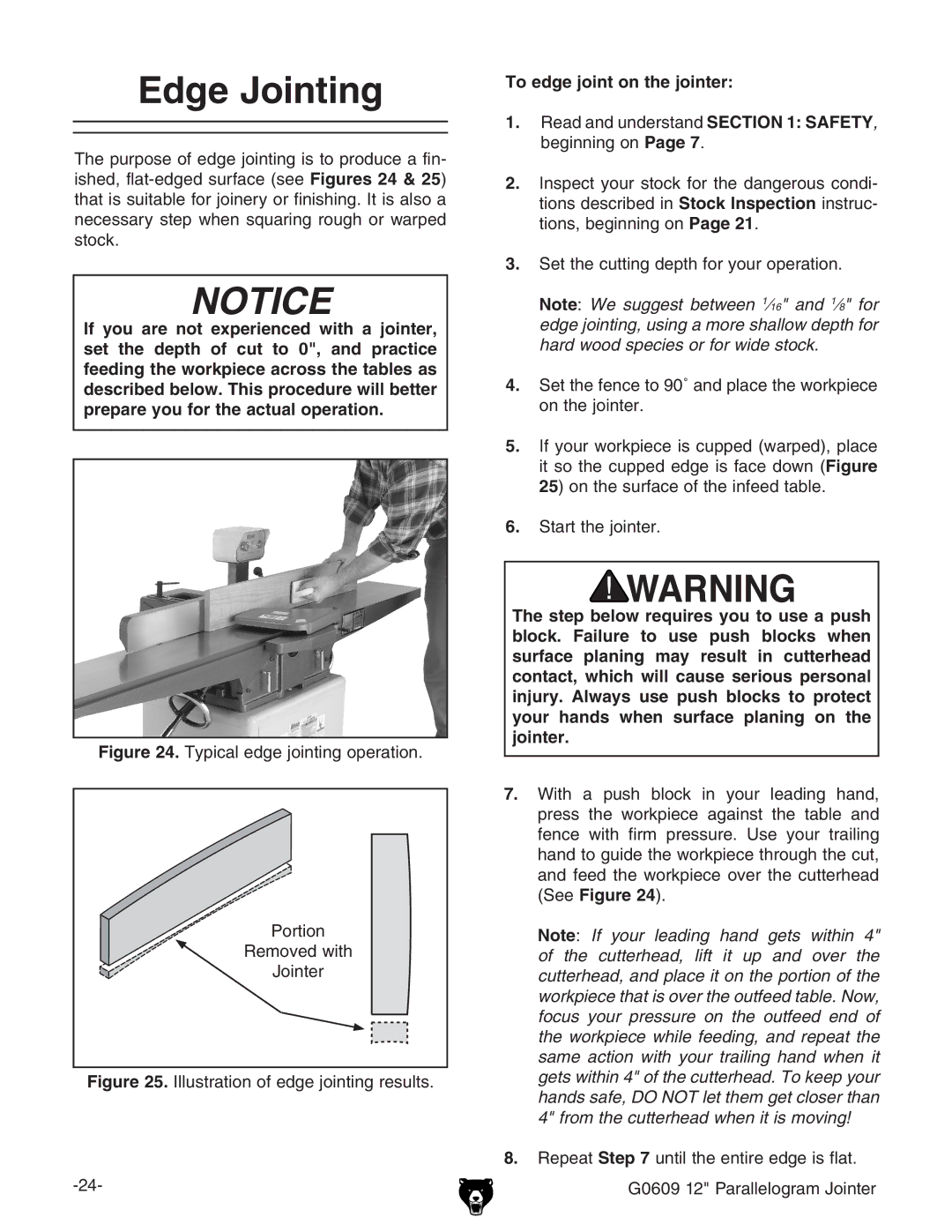

Figure 25. Illustration of edge jointing results.

To edge joint on the jointer:

1.Read and understand SECTION 1: SAFETY, beginning on Page 7.

2.Inspect your stock for the dangerous condi- tions described in Stock Inspection instruc- tions, beginning on Page 21.

3.Set the cutting depth for your operation.

Note: We suggest between 1⁄16" and 1⁄8" for edge jointing, using a more shallow depth for hard wood species or for wide stock.

4.Set the fence to 90˚ and place the workpiece on the jointer.

5.If your workpiece is cupped (warped), place it so the cupped edge is face down (Figure 25) on the surface of the infeed table.

6.Start the jointer.

The step below requires you to use a push block. Failure to use push blocks when surface planing may result in cutterhead contact, which will cause serious personal injury. Always use push blocks to protect your hands when surface planing on the jointer.

7.With a push block in your leading hand, press the workpiece against the table and fence with firm pressure. Use your trailing hand to guide the workpiece through the cut, and feed the workpiece over the cutterhead (See Figure 24).

Note: If your leading hand gets within 4" of the cutterhead, lift it up and over the cutterhead, and place it on the portion of the workpiece that is over the outfeed table. Now, focus your pressure on the outfeed end of the workpiece while feeding, and repeat the same action with your trailing hand when it gets within 4" of the cutterhead. To keep your hands safe, DO NOT let them get closer than 4" from the cutterhead when it is moving!

8.Repeat Step 7 until the entire edge is flat. G0609 12" Parallelogram Jointer