Mounting to Shop

Floor

Although not required, we recommend that you mount your new machine to the floor. Because this is an optional step and floor materials may vary, floor mounting hardware is not included. However, you must level your machine with a precision level.

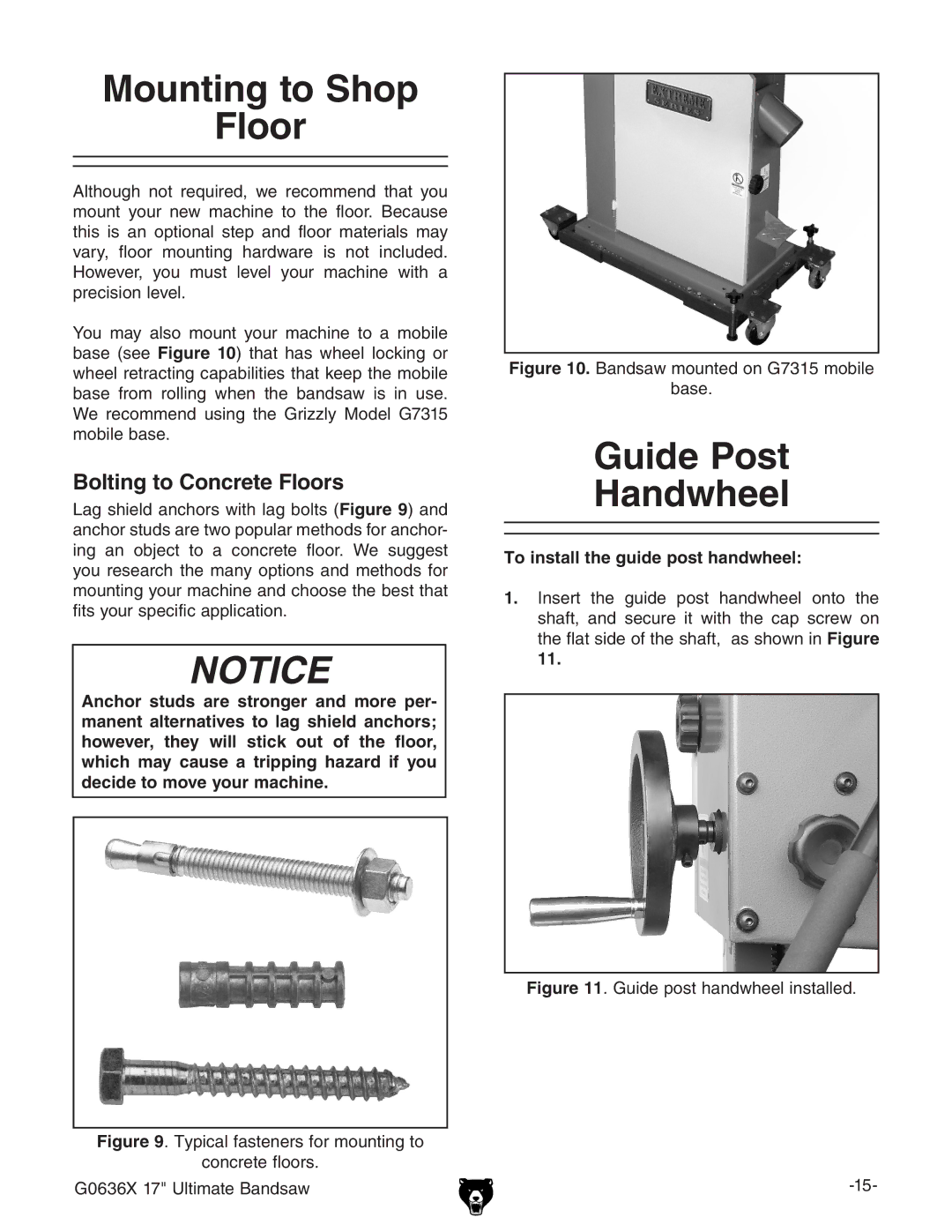

You may also mount your machine to a mobile base (see Figure 10) that has wheel locking or wheel retracting capabilities that keep the mobile base from rolling when the bandsaw is in use. We recommend using the Grizzly Model G7315 mobile base.

Bolting to Concrete Floors

Lag shield anchors with lag bolts (Figure 9) and anchor studs are two popular methods for anchor- ing an object to a concrete floor. We suggest you research the many options and methods for mounting your machine and choose the best that fits your specific application.

NOTICE

Anchor studs are stronger and more per- manent alternatives to lag shield anchors; however, they will stick out of the floor, which may cause a tripping hazard if you decide to move your machine.

Figure 9. Typical fasteners for mounting to

concrete floors.

G0636X 17" Ultimate Bandsaw

Figure 10. Bandsaw mounted on G7315 mobile

base.

Guide Post

Handwheel

To install the guide post handwheel:

1.Insert the guide post handwheel onto the shaft, and secure it with the cap screw on the flat side of the shaft, as shown in Figure 11.