Adjusting Wheel and

Blade Brushes

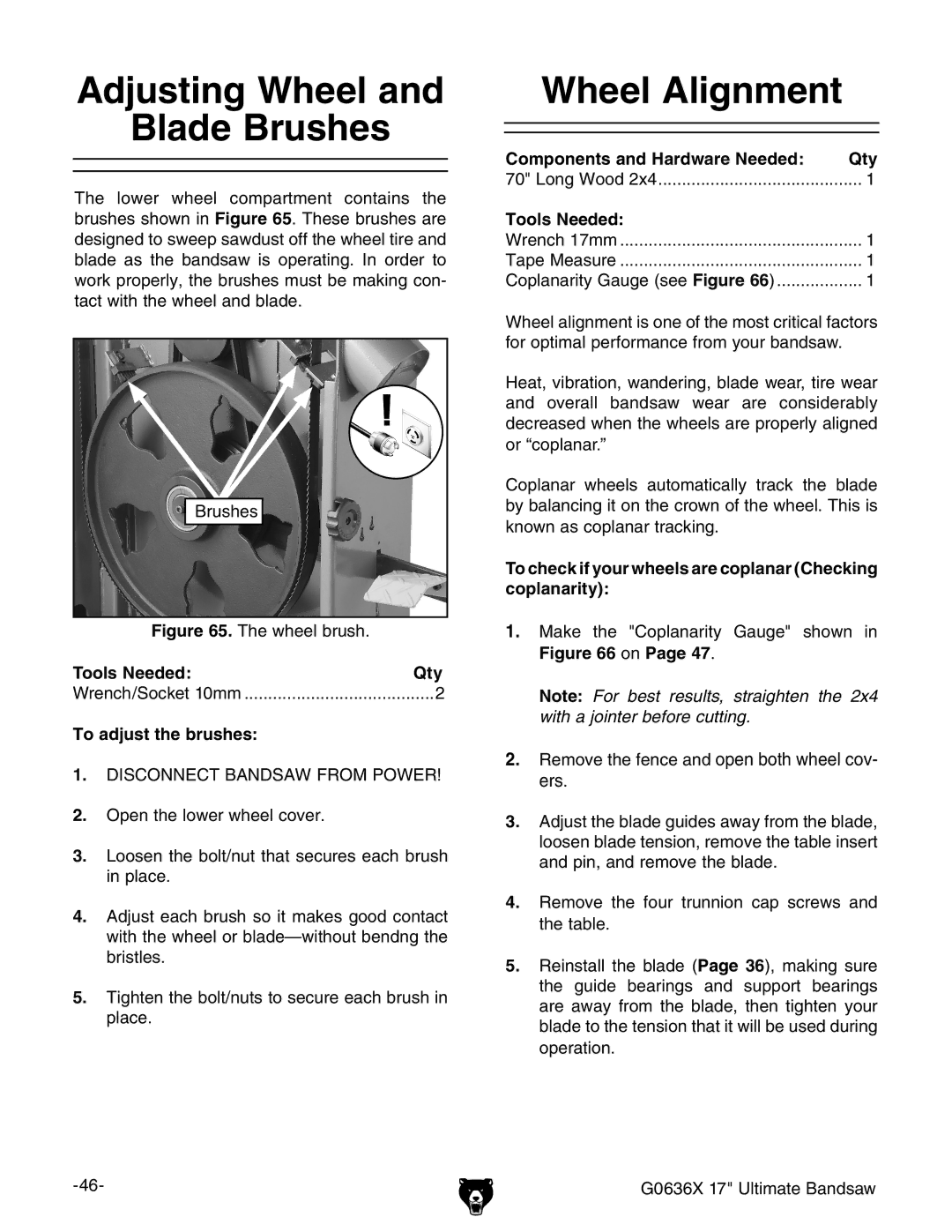

The lower wheel compartment contains the brushes shown in Figure 65. These brushes are designed to sweep sawdust off the wheel tire and blade as the bandsaw is operating. In order to work properly, the brushes must be making con- tact with the wheel and blade.

Brushes

Figure 65. The wheel brush. |

|

Tools Needed: | Qty |

Wrench/Socket 10mm | 2 |

To adjust the brushes: |

|

1.DISCONNECT BANDSAW FROM POWER!

2.Open the lower wheel cover.

3.Loosen the bolt/nut that secures each brush in place.

4.Adjust each brush so it makes good contact with the wheel or

5.Tighten the bolt/nuts to secure each brush in place.

Wheel Alignment

Components and Hardware Needed: | Qty |

70" Long Wood 2x4 | 1 |

Tools Needed: |

|

Wrench 17mm | 1 |

Tape Measure | 1 |

Coplanarity Gauge (see Figure 66) | 1 |

Wheel alignment is one of the most critical factors for optimal performance from your bandsaw.

Heat, vibration, wandering, blade wear, tire wear and overall bandsaw wear are considerably decreased when the wheels are properly aligned or “coplanar.”

Coplanar wheels automatically track the blade by balancing it on the crown of the wheel. This is known as coplanar tracking.

To check if your wheels are coplanar (Checking coplanarity):

1.Make the "Coplanarity Gauge" shown in Figure 66 on Page 47.

Note: For best results, straighten the 2x4 with a jointer before cutting.

2.Remove the fence and open both wheel cov- ers.

3.Adjust the blade guides away from the blade, loosen blade tension, remove the table insert and pin, and remove the blade.

4.Remove the four trunnion cap screws and the table.

5.Reinstall the blade (Page 36), making sure the guide bearings and support bearings are away from the blade, then tighten your blade to the tension that it will be used during operation.