The most common causes of blade breakage are:

•Faulty alignment and adjustment of the guides.

•Forcing or twisting a wide blade around a curve of short radius.

•Feeding the workpiece into the blade too fast.

•Tooth dullness or absence of sufficient set.

•Incorrect tension.

•Top blade guide assembly set too high above the workpiece.

•Using a blade with a lumpy or improperly fin- ished braze or weld.

•Continuously running the bandsaw when not in use.

Blade Changes

Always disconnect power to the machine when changing blades. Failure to do this may result in serious personal injury.

All saw blades are dan- gerous and may cause personalinjury.Toreduce the risk of being injured, wear leather gloves when handling saw blades.

To remove a blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Release the blade tension.

3.Remove the table insert and the table pin. Adjust the upper and lower guide bearings as far away as possible from the blade.

4.Open the upper and lower wheel covers, and with gloved hands, slide the blade off of both wheels.

5.Slide the blade through the slot in the table.

To replace a blade:

1.Slide the blade through the table slot, ensur- ing that the teeth are pointing forward and down toward the table. Note: If the teeth will not point downward in any orientation, the blade is

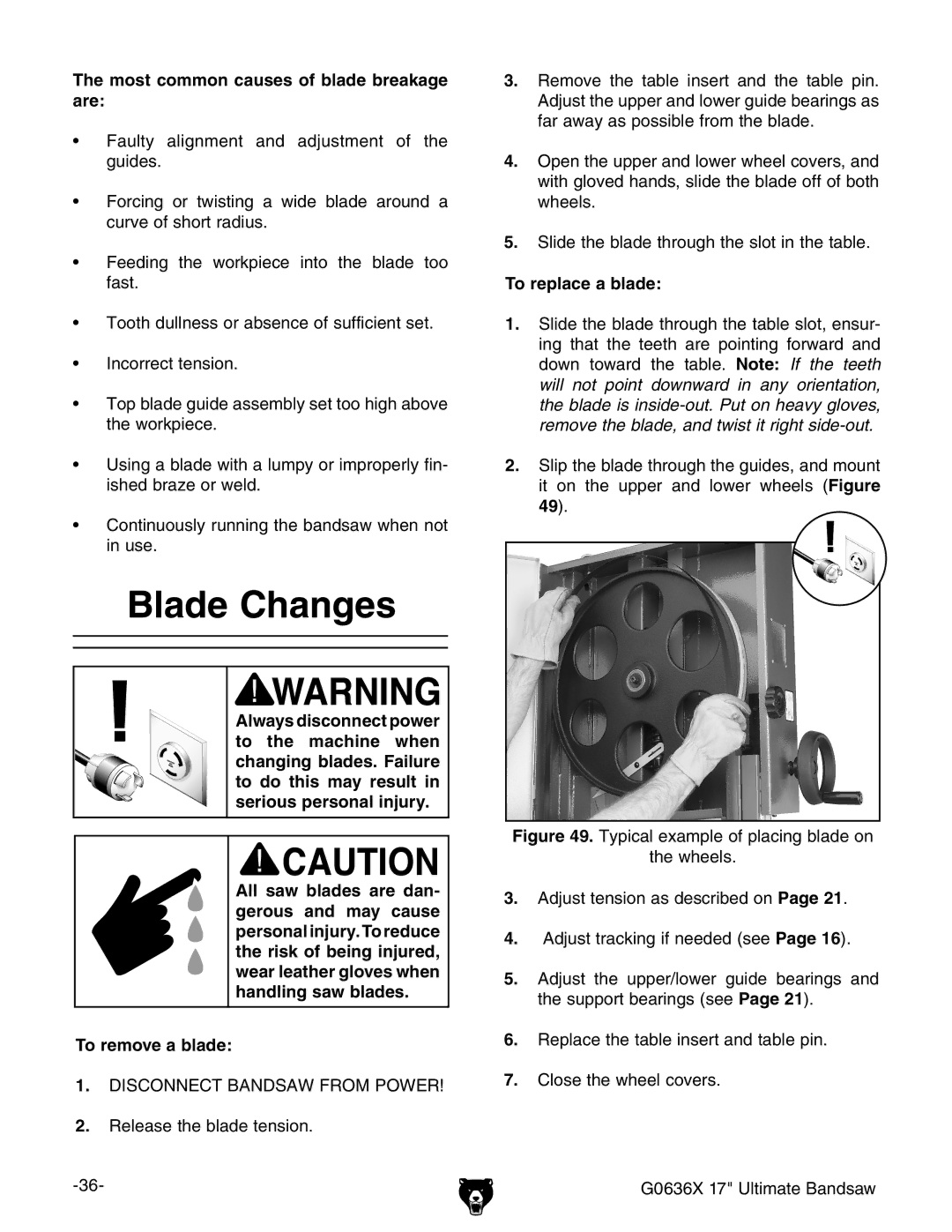

2.Slip the blade through the guides, and mount it on the upper and lower wheels (Figure 49).