Checking and

Tensioning V-Belts

To ensure optimum power transmission from the motor to the blade, the

Tools Needed: | Qty |

Ruler | 1 |

Hex Wrench 6mm | 1 |

Wrench 17mm | 1 |

To check the |

|

1.DISCONNECT BANDSAW FROM POWER!

2.Open the wheel covers.

3.Note the condition of the

4.Push the center of the

�����

�����

����������

�������

�����

Figure 61. V-belt deflection.

To tension the V-belt:

1.DISCONNECT BANDSAW FROM POWER!

2.Open the wheel covers.

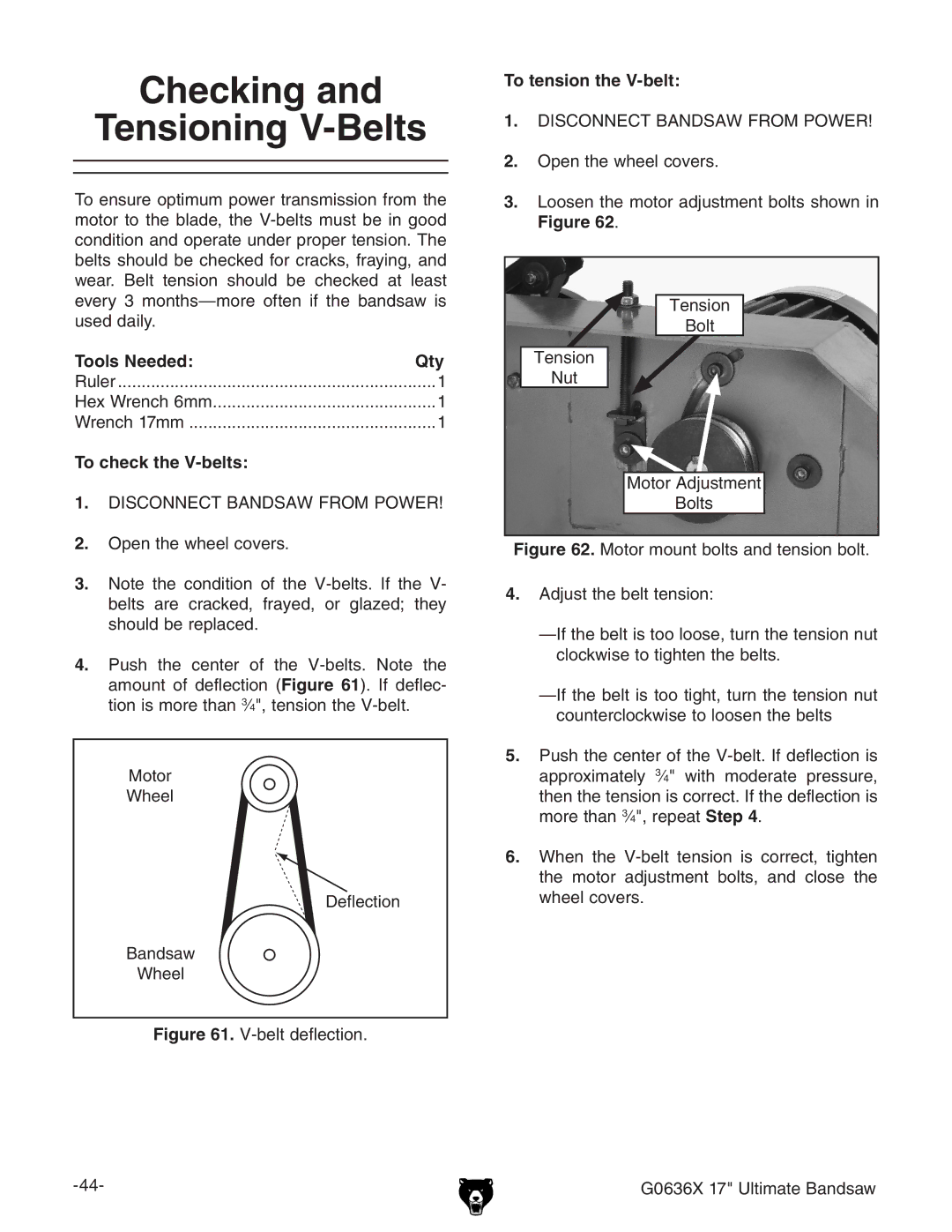

3.Loosen the motor adjustment bolts shown in Figure 62.

Tension

Bolt

Tension

Nut

Motor Adjustment

Bolts

Figure 62. Motor mount bolts and tension bolt.

4.Adjust the belt tension:

—If the belt is too loose, turn the tension nut clockwise to tighten the belts.

—If the belt is too tight, turn the tension nut counterclockwise to loosen the belts

5.Push the center of the V-belt. If deflection is approximately 3⁄4" with moderate pressure, then the tension is correct. If the deflection is more than 3⁄4", repeat Step 4.

6.When the V-belt tension is correct, tighten the motor adjustment bolts, and close the wheel covers.

G0636X 17" Ultimate Bandsaw |