Leveling & Mounting

Generally, you can either bolt your machine to the floor or mount it on machine mounts. Although not required, we recommend that you secure the machine to the floor and level it while doing so. Because this is an optional step and floor materi- als may vary, hardware for securing the machine to the floor is not included.

Unless otherwise specified by your local codes, this machine MUST be secured to the floor if it is permanently connected (hardwired) to the power supply.

Leveling

Leveling machinery helps precision components, such as dovetail ways, remain straight and flat during the lifespan of the machine. Components on an unleveled machine may slowly twist due to the dynamic loads placed on the machine during operation.

For best results, use a precision level that is at least 12" long and sensitive enough to show a distinct movement when a 0.003" shim (approxi- mately the thickness of one sheet of standard newspaper) is placed under one end of the level.

See Figure 7 for an example of a high precision level available from Grizzly.

Figure 7. Example of a precision level

(Model H2683 shown).

Model G0747/G0748 (Mfg. Since 8/12)

Bolting to Concrete Floors

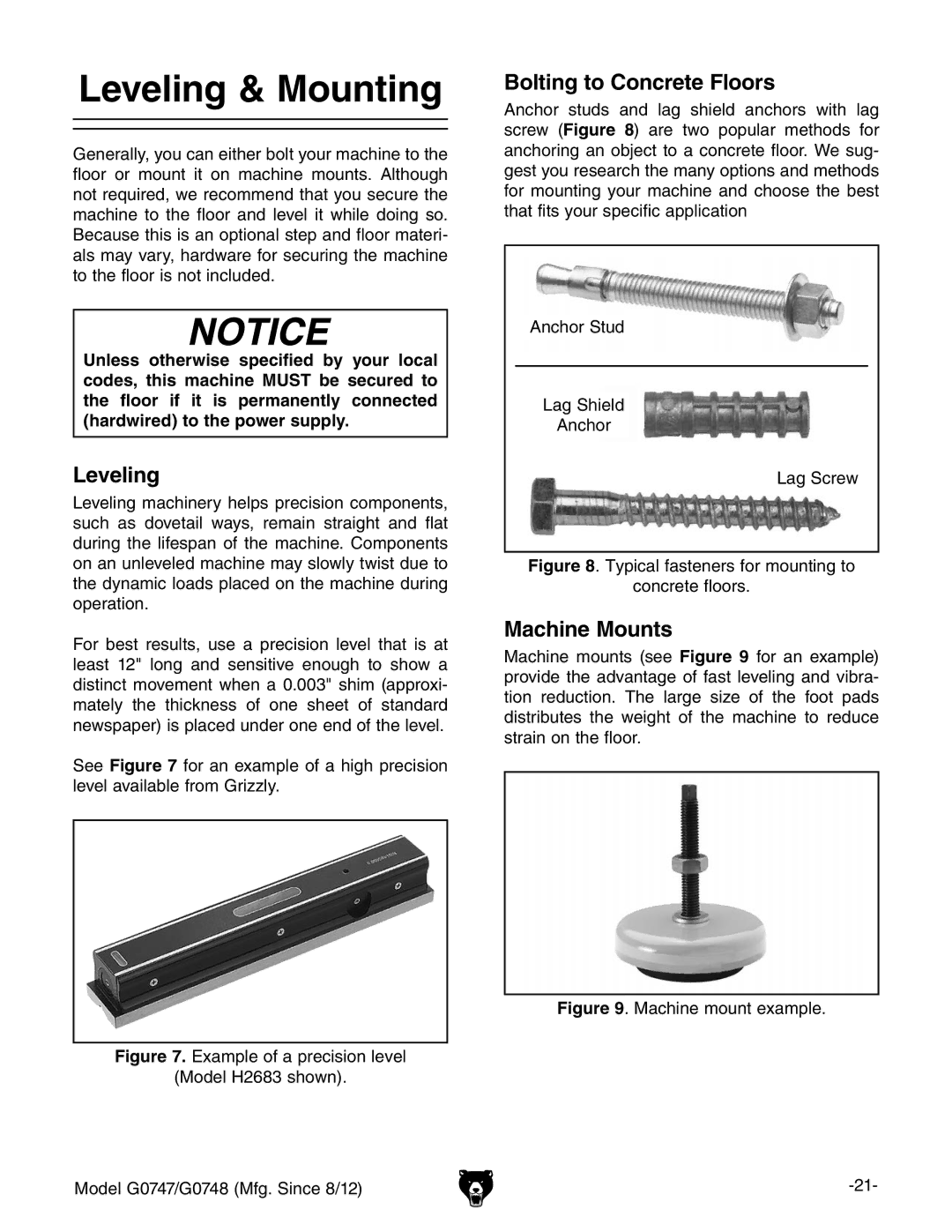

Anchor studs and lag shield anchors with lag screw (Figure 8) are two popular methods for anchoring an object to a concrete floor. We sug- gest you research the many options and methods for mounting your machine and choose the best that fits your specific application

Anchor stud

lag shield

Anchor

lag screw

Figure 8. Typical fasteners for mounting to

concrete floors.

Machine Mounts

Machine mounts (see Figure 9 for an example) provide the advantage of fast leveling and vibra- tion reduction. The large size of the foot pads distributes the weight of the machine to reduce strain on the floor.