Table Movement

The mill table moves in three directions, as illus- trated in Figure 16:

•

•

•

These movements are controlled by table ball handles and the

(Left & Right)

![]()

![]() Cross Travel

Cross Travel ![]()

![]() (In & Out)

(In & Out)

Vertical Elevation

(Up & Down)

Figure 16. The directions of table movement.

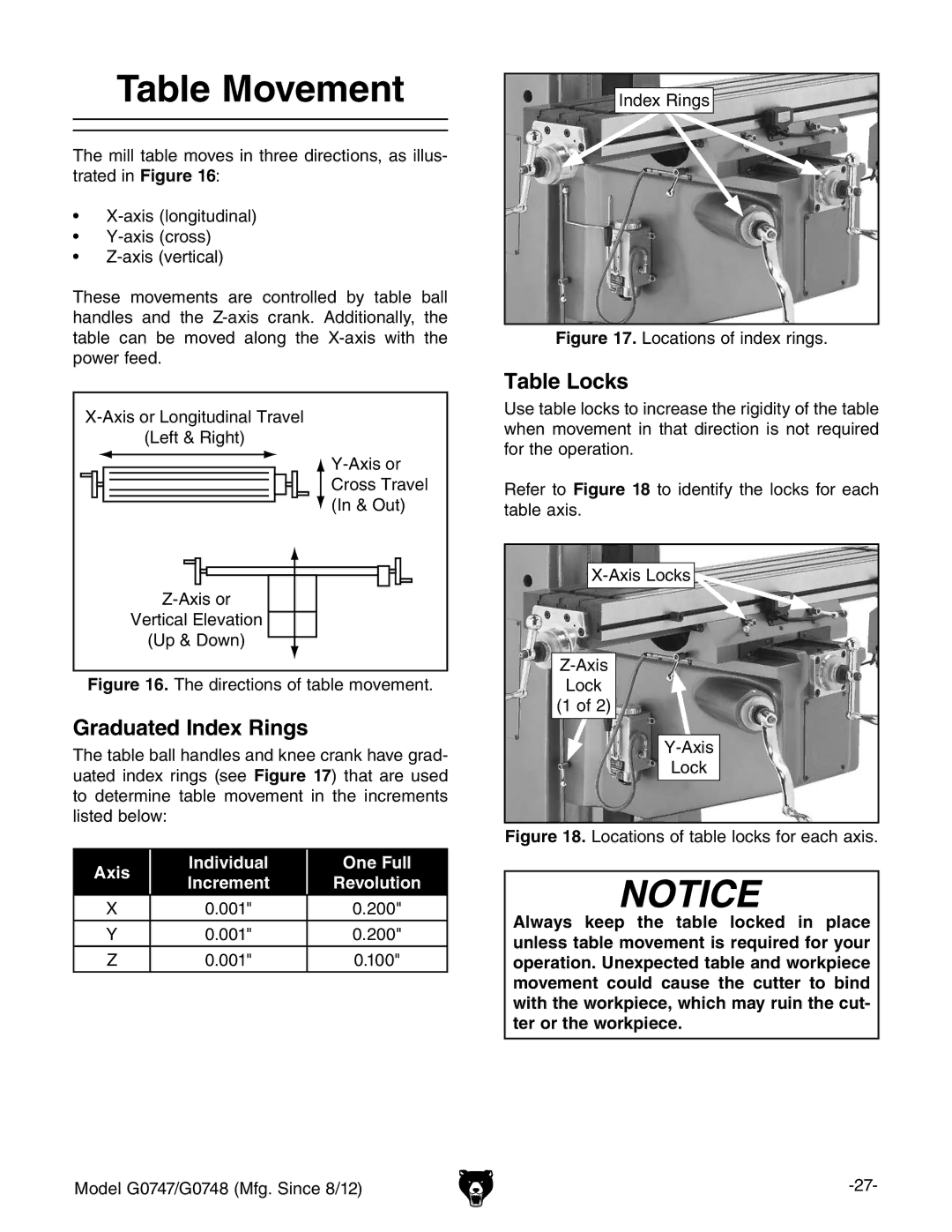

Graduated Index Rings

The table ball handles and knee crank have grad- uated index rings (see Figure 17) that are used to determine table movement in the increments listed below:

Axis | Individual | One Full | |

Increment | Revolution | ||

| |||

X | 0.001" | 0.200" | |

Y | 0.001" | 0.200" | |

Z | 0.001" | 0.100" |

Model G0747/G0748 (Mfg. Since 8/12)

Index Rings

Figure 17. Locations of index rings.

Table Locks

Use table locks to increase the rigidity of the table when movement in that direction is not required for the operation.

Refer to Figure 18 to identify the locks for each table axis.

![]()

Lock

(1 of 2)

Lock

Figure 18. Locations of table locks for each axis.

Always keep the table locked in place unless table movement is required for your operation. Unexpected table and workpiece movement could cause the cutter to bind with the workpiece, which may ruin the cut- ter or the workpiece.