Lubrication

The mill has numerous moving

Other than the lubrication points covered in this section, all other bearings are internally lubricated and sealed at the factory. Simply leave them alone unless they need to be replaced.

Before performing any lubrication task, DISCONneCT THe MILL FROM POWER!

Important: Before adding lubricant, clean the debris and grime from the oil cup or grease fitting and the immediate area to prevent contamination of the new lubricant.

Use the schedule and information in Figure 51 as a daily guide for lubrication tasks. Follow the referenced sections on the following pages for detailed instructions.

The following recommended lubrication schedule is based on light to medium mill usage. Keeping in mind that lubrication helps to protect the value and operation of the mill, you may need to perform the lubri- cation tasks more frequently depending on your usage.

| Frequency | Page | |

Lubrication Task | (Hours of | Ref. | |

| Operation) | ||

Quill | 4 hrs. | This | |

Page | |||

|

| ||

Table Ways | 45 | ||

Oiler) | |||

|

| ||

|

|

| |

Headstock Gearing | 40 hrs. | 45 | |

|

|

| |

Ram Ways | 40 hrs. | 46 | |

Table Elevation Leadscrew | 40 hrs. | 46 | |

|

| ||

Power Feed Gears | 160 hrs. | 47 |

Figure 51. Recommended lubrication tasks, schedules, and instruction page references.

Failure to follow reasonable lubrication practices as instructed in this manual for the mill could lead to premature failure of the mill and will void the warranty.

Quill

Oil Type | Model T23962 or ISo 68 Equivalent | |

Oil Amount | Fill Oil Cup | |

Check/Add Frequency | 4 hrs. of Operation | |

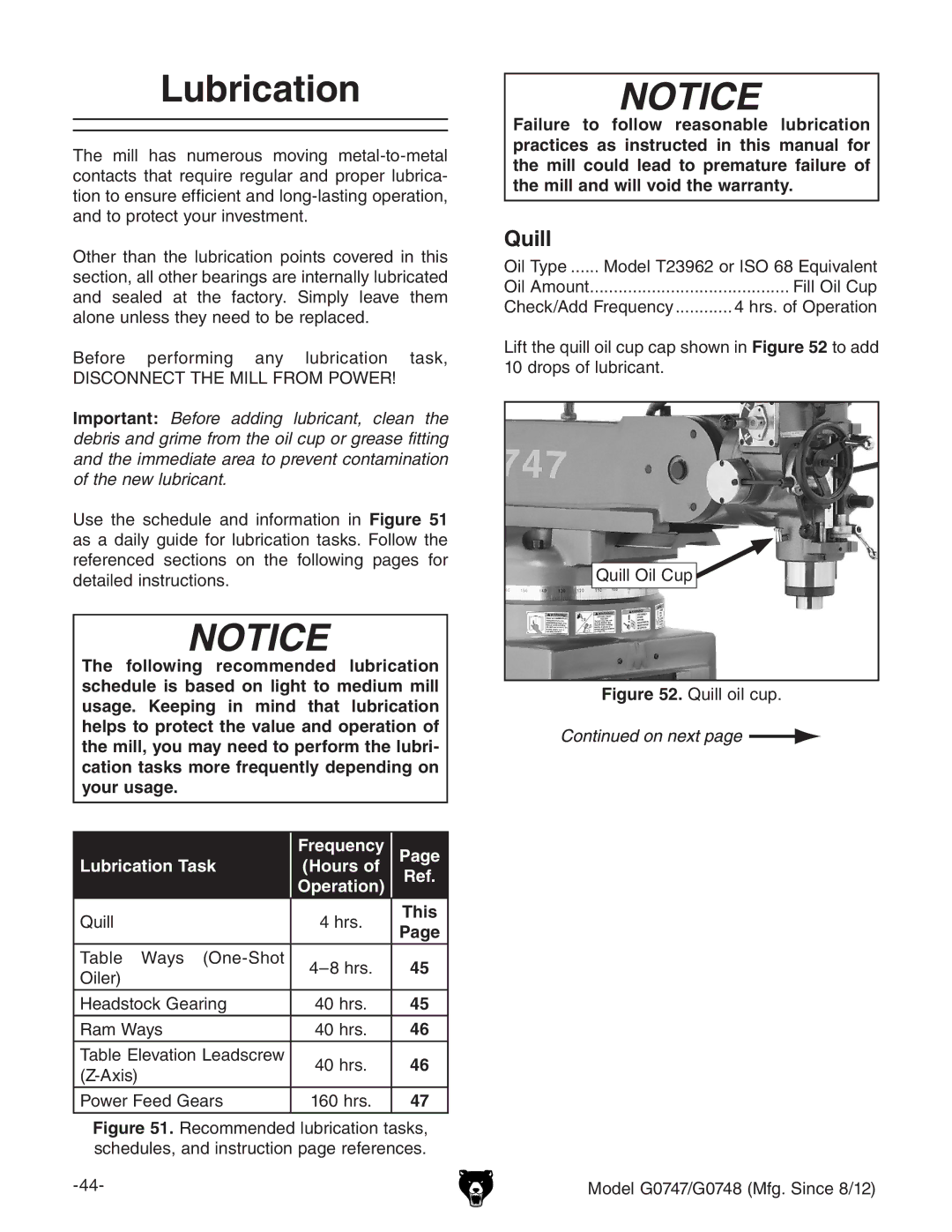

Lift the quill oil cup cap shown in Figure 52 to add 10 drops of lubricant.

Quill Oil Cup![]()