Power Feed Gears |

| |

Grease Type | NLgi 2 or Equivalent | |

Grease Amount | Two Pumps of Grease Gun | |

Check/Add Frequency | 160 hrs. of Operation | |

Tool Needed |

| Qty |

Wrench 19mm | 1 | |

To lubricate the power feed gears:

1.disCONNECT MILL FROM POWER!

2.remove the hex nut and ball handle from the power unit end of the

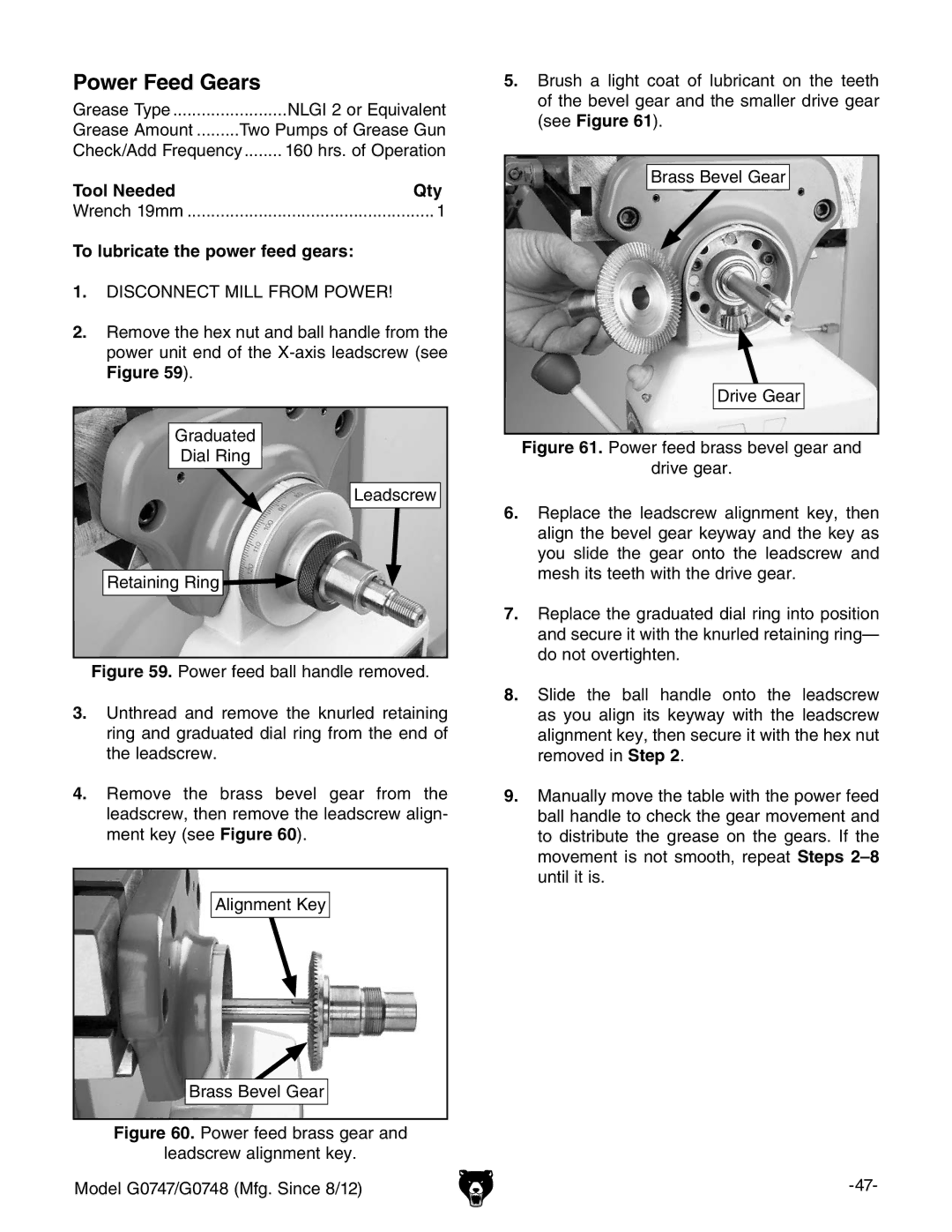

Graduated

Dial Ring

Leadscrew

Retaining Ring![]()