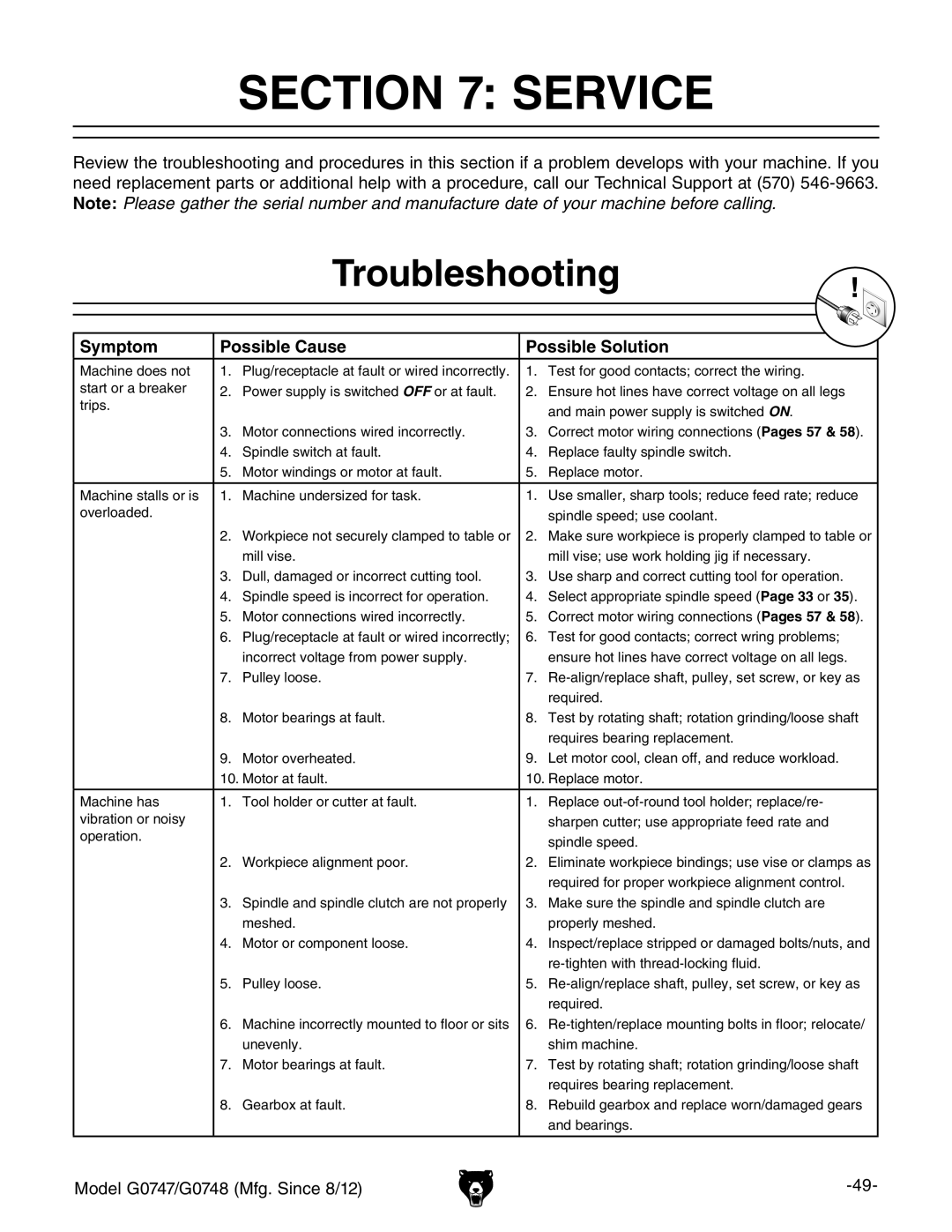

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

Machine does not | 1. | plug/receptacle at fault or wired incorrectly. | 1. | test for good contacts; correct the wiring. |

start or a breaker | 2. | power supply is switched OFF or at fault. | 2. | ensure hot lines have correct voltage on all legs |

trips. |

|

|

| and main power supply is switched ON. |

|

|

|

| |

| 3. | Motor connections wired incorrectly. | 3. | Correct motor wiring connections (Pages 57 & 58). |

| 4. | spindle switch at fault. | 4. | replace faulty spindle switch. |

| 5. | Motor windings or motor at fault. | 5. | replace motor. |

|

|

|

|

|

Machine stalls or is | 1. | Machine undersized for task. | 1. | use smaller, sharp tools; reduce feed rate; reduce |

overloaded. |

|

|

| spindle speed; use coolant. |

| 2. | Workpiece not securely clamped to table or | 2. | Make sure workpiece is properly clamped to table or |

|

| mill vise. |

| mill vise; use work holding jig if necessary. |

| 3. | dull, damaged or incorrect cutting tool. | 3. | use sharp and correct cutting tool for operation. |

| 4. | spindle speed is incorrect for operation. | 4. | select appropriate spindle speed (Page 33 or 35). |

| 5. | Motor connections wired incorrectly. | 5. | Correct motor wiring connections (Pages 57 & 58). |

| 6. | plug/receptacle at fault or wired incorrectly; | 6. | test for good contacts; correct wring problems; |

|

| incorrect voltage from power supply. |

| ensure hot lines have correct voltage on all legs. |

| 7. | pulley loose. | 7. | |

|

|

|

| required. |

| 8. | Motor bearings at fault. | 8. | test by rotating shaft; rotation grinding/loose shaft |

|

|

|

| requires bearing replacement. |

| 9. | Motor overheated. | 9. | let motor cool, clean off, and reduce workload. |

| 10. Motor at fault. | 10. replace motor. | ||

|

|

|

|

|

Machine has | 1. | tool holder or cutter at fault. | 1. | replace |

vibration or noisy |

|

|

| sharpen cutter; use appropriate feed rate and |

operation. |

|

|

| spindle speed. |

|

|

|

| |

| 2. | Workpiece alignment poor. | 2. | eliminate workpiece bindings; use vise or clamps as |

|

|

|

| required for proper workpiece alignment control. |

| 3. | spindle and spindle clutch are not properly | 3. | Make sure the spindle and spindle clutch are |

|

| meshed. |

| properly meshed. |

| 4. | Motor or component loose. | 4. | inspect/replace stripped or damaged bolts/nuts, and |

|

|

|

| |

| 5. | pulley loose. | 5. | |

|

|

|

| required. |

| 6. | Machine incorrectly mounted to floor or sits | 6. | |

|

| unevenly. |

| shim machine. |

| 7. | Motor bearings at fault. | 7. | test by rotating shaft; rotation grinding/loose shaft |

|

|

|

| requires bearing replacement. |

| 8. | gearbox at fault. | 8. | rebuild gearbox and replace worn/damaged gears |

|

|

|

| and bearings. |

|

|

|

| |

Model G0747/G0748 (Mfg. Since 8/12) |

| |||