Spindle Break-In

Before subjecting the spindle to operational loads, it is essential to complete the

After spindle

The

DO NOT perform this procedure indepen- dently of the Test Run section. The drill press could be seriously damaged if the controls are set differently than instructed in that section.

Model G0756 (Mfg. Since 2/13)

To perform the spindle break-in procedure:

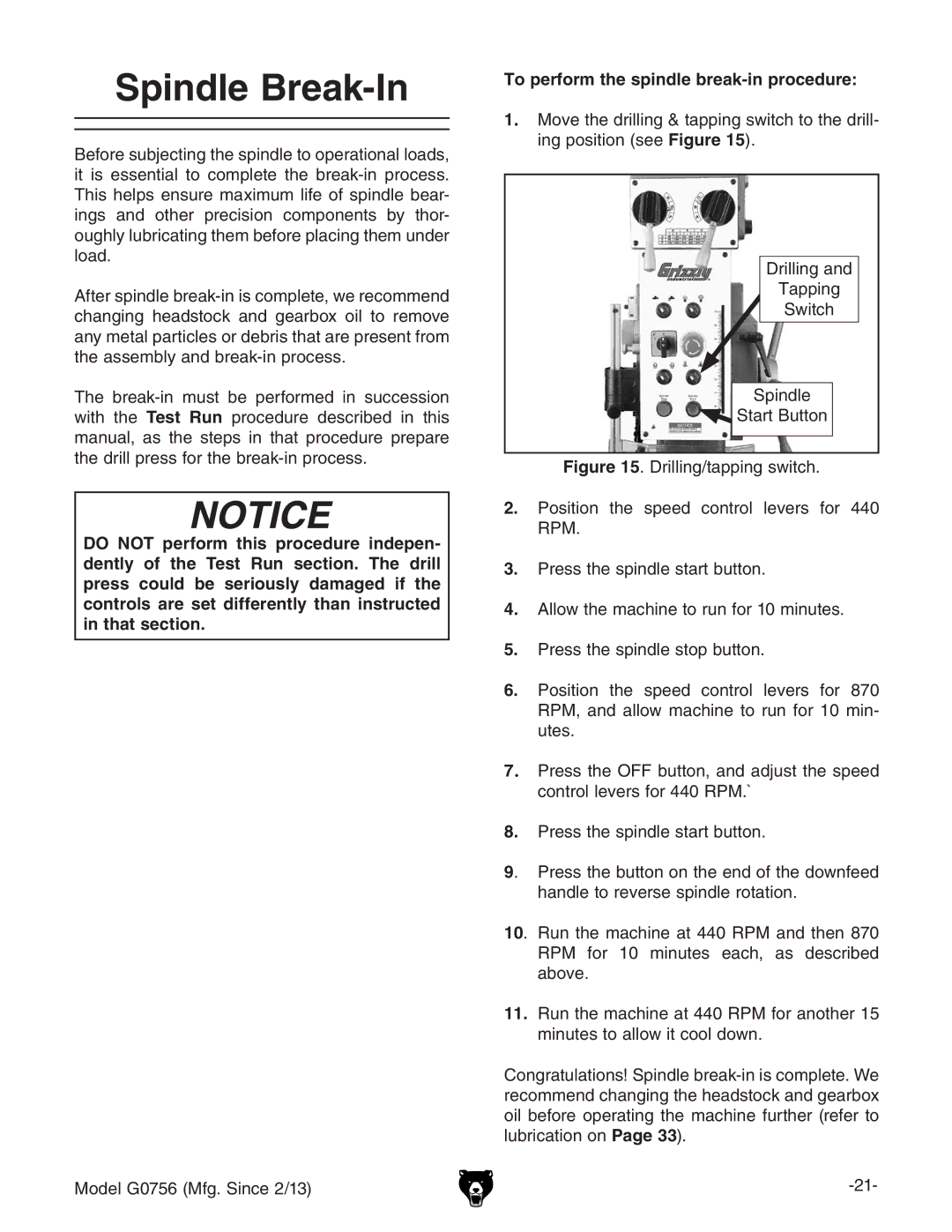

1. Move the drilling & tapping switch to the drill- ing position (see Figure 15).

Drilling and

Tapping

Switch

Spindle

![]() Start Button

Start Button

Figure 15. Drilling/tapping switch.

2.Position the speed control levers for 440 RPM.

3.Press the spindle start button.

4.Allow the machine to run for 10 minutes.

5.Press the spindle stop button.

6.Position the speed control levers for 870 RPM, and allow machine to run for 10 min- utes.

7. Press the OFF button, and adjust the speed control levers for 440 RPM.`

8.Press the spindle start button.