Ball Oilers

Oil Type | Model T23963 or Iso 32 Equivalent | |

Oil Amount | ||

Lubrication Frequency | 8 Hours of Operation | |

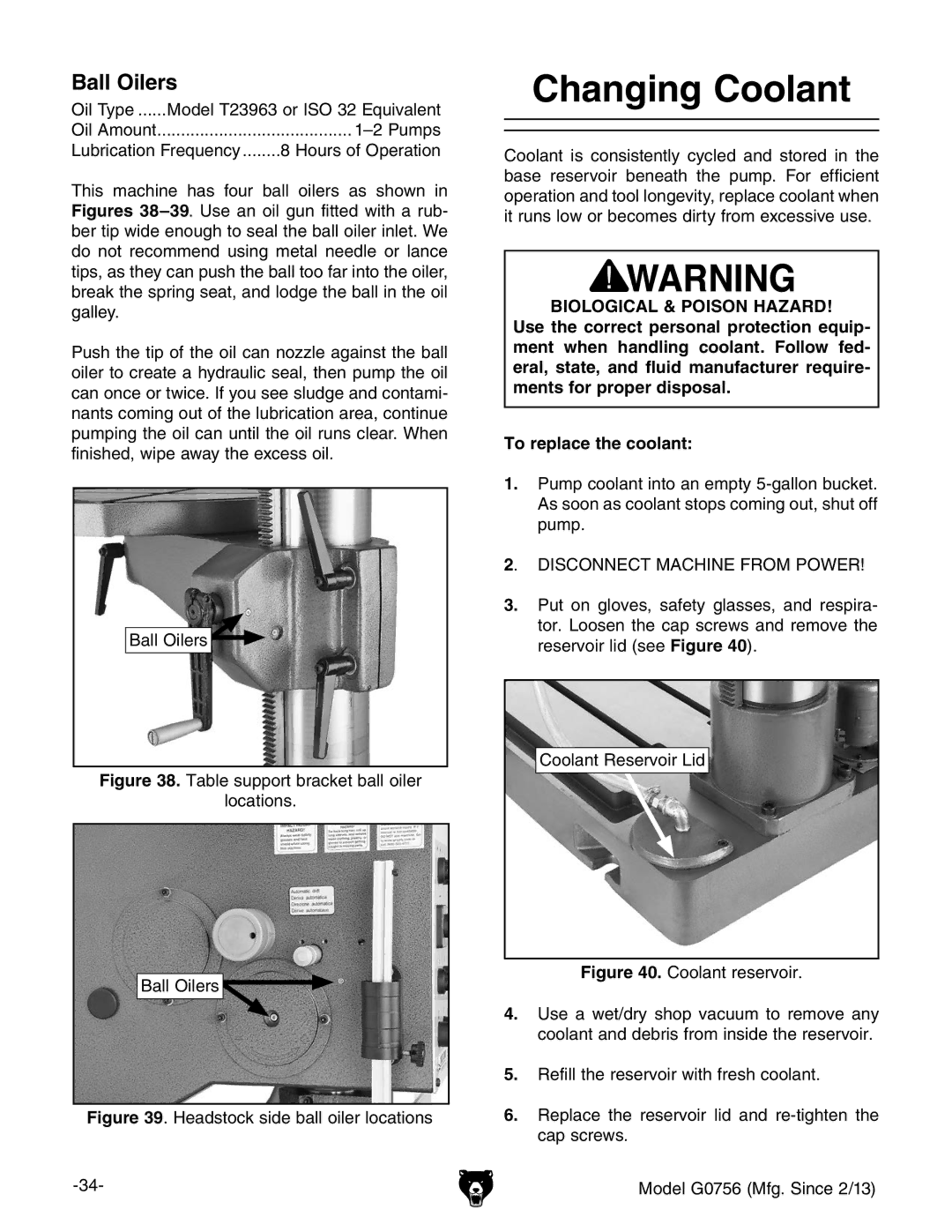

This machine has four ball oilers as shown in Figures

Push the tip of the oil can nozzle against the ball oiler to create a hydraulic seal, then pump the oil can once or twice. If you see sludge and contami- nants coming out of the lubrication area, continue pumping the oil can until the oil runs clear. When finished, wipe away the excess oil.

Ball Oilers ![]()

Figure 38. Table support bracket ball oiler

locations.

Ball Oilers

Figure 39. Headstock side ball oiler locations

Changing Coolant

Coolant is consistently cycled and stored in the base reservoir beneath the pump. For efficient operation and tool longevity, replace coolant when it runs low or becomes dirty from excessive use.

BIOLOGICAL & POISON HAZARD!

Use the correct personal protection equip- ment when handling coolant. Follow fed- eral, state, and fluid manufacturer require- ments for proper disposal.

To replace the coolant:

1.Pump coolant into an empty

2. DISCONNECT MACHINE FROM POWER!

3.Put on gloves, safety glasses, and respira- tor. Loosen the cap screws and remove the reservoir lid (see Figure 40).

Coolant Reservoir Lid