Lubrication

For the quill, table, and column, an occasional application of light machine oil is all that is neces- sary. Before applying lubricant, clean off any dust or metal chips.

Your goal is to achieve adequate lubrication. Too much lubrication will attract dirt and dust. Various parts of your machine could lose their freedom of movement as a result.

Headstock Lubrication

Oil Type | Model T23963 or Iso 32 Equivalent | |

Oil Amount | 43⁄4 quarts | |

Lubrication Frequency | ............................ Annually | |

The headstock uses an oil pump to lubricate the gears. For this machine, use Iso 68 machine oil. Check the oil level every day (see Step 4). Change oil annually.

To change oil in headstock:

1. remove the oil fill plug on top of the machine (see Figure 35).

![]()

![]() Oil Fill Plug

Oil Fill Plug

Oil Drain Plug

Figure 35. Oil fill and drain locations.

2. Remove the drain plug, and allow old oil to drain into an appropriate container.

3. Replace and tighten the drain plug.

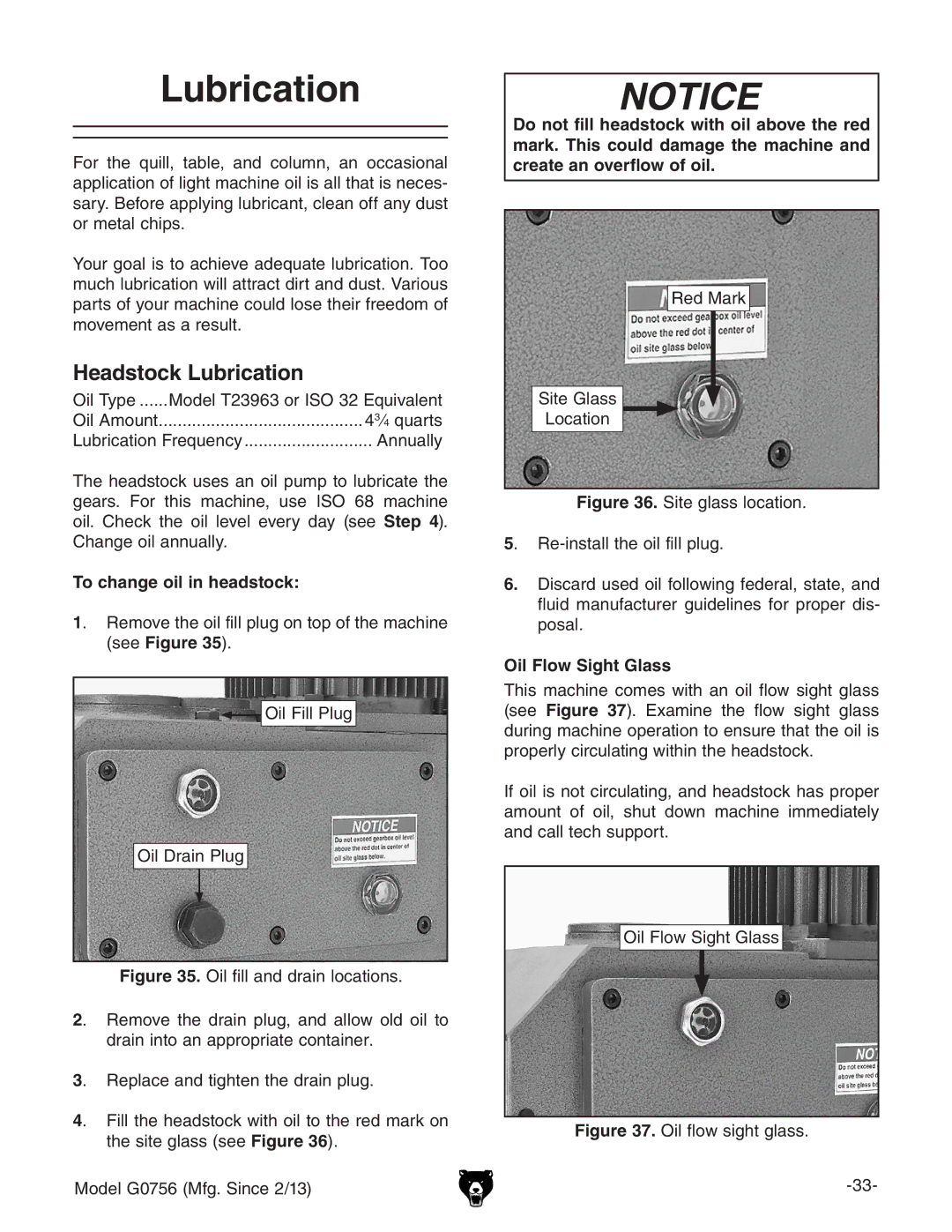

4. Fill the headstock with oil to the red mark on the site glass (see Figure 36).

Model G0756 (Mfg. Since 2/13)

Do not fill headstock with oil above the red mark. This could damage the machine and create an overflow of oil.

Red Mark

Site Glass

Location

Figure 36. Site glass location.

5. Re-install the oil fill plug.

6.Discard used oil following federal, state, and fluid manufacturer guidelines for proper dis- posal.

Oil Flow Sight Glass

This machine comes with an oil flow sight glass (see Figure 37). Examine the flow sight glass during machine operation to ensure that the oil is properly circulating within the headstock.

If oil is not circulating, and headstock has proper amount of oil, shut down machine immediately and call tech support.

Oil Flow Sight Glass