Installing Tapered Tooling

1.DISCONNECT MACHINE FROM POWER!

2.Clean tooling and spindle tapers to ensure proper seating.

3.Insert the MT#4 tooling into the spindle, and maneuver the tang until it engages with the slot at the end of the spindle.

4.Use a rubber or wooden mallet to seat the tooling into the spindle by firmly tapping from the bottom.

Note: If installing a drill chuck, make sure to retract the jaws to prevent damage to chuck.

Removing Tooling with Automatic Drift

1.DISCONNECT MACHINE FROM POWER!

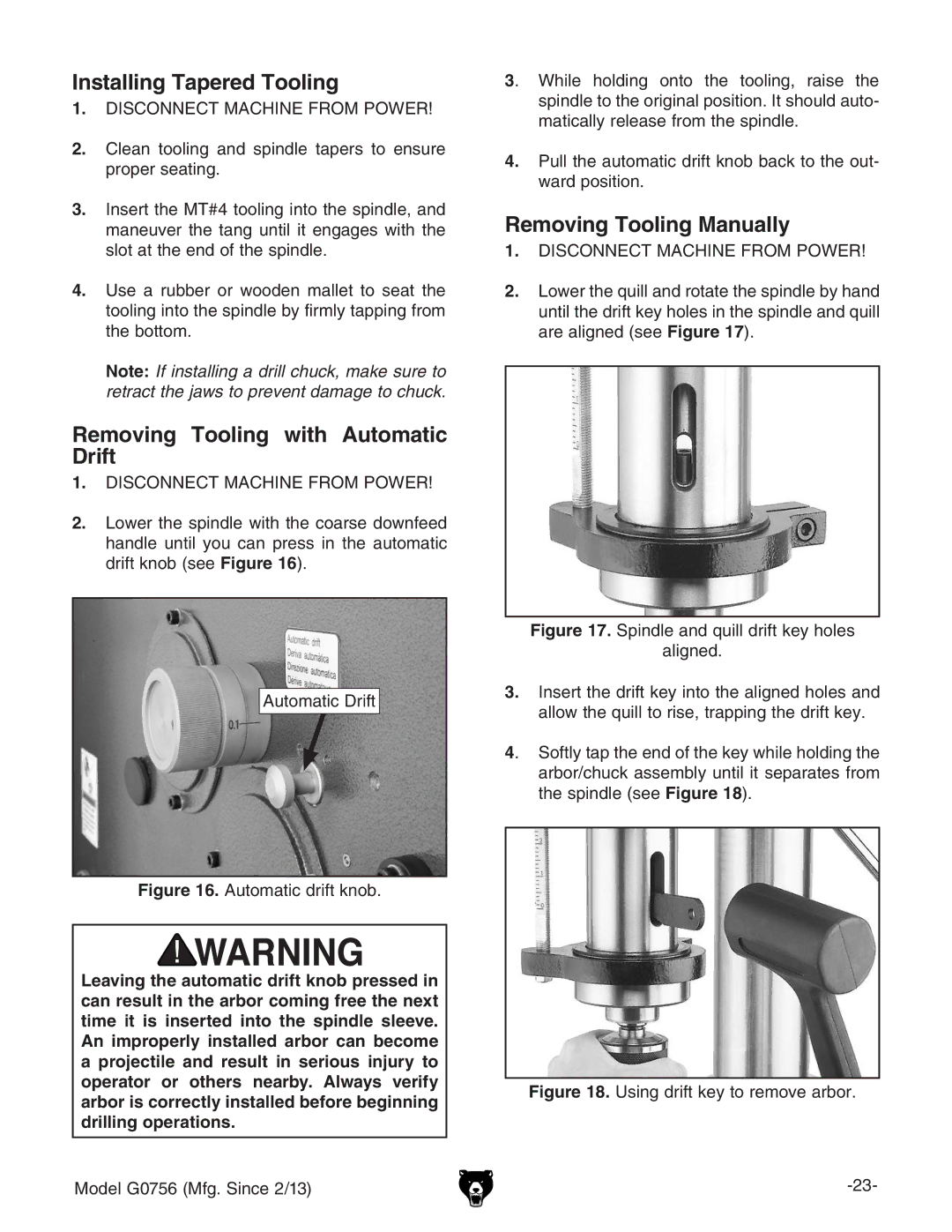

2.Lower the spindle with the coarse downfeed handle until you can press in the automatic drift knob (see Figure 16).

Automatic Drift

Figure 16. Automatic drift knob.

Leaving the automatic drift knob pressed in can result in the arbor coming free the next time it is inserted into the spindle sleeve. An improperly installed arbor can become a projectile and result in serious injury to operator or others nearby. Always verify arbor is correctly installed before beginning drilling operations.

Model G0756 (Mfg. Since 2/13)

3. While holding onto the tooling, raise the spindle to the original position. It should auto- matically release from the spindle.

4.Pull the automatic drift knob back to the out- ward position.

Removing Tooling Manually

1.DISCONNECT MACHINE FROM POWER!

2.lower the quill and rotate the spindle by hand until the drift key holes in the spindle and quill are aligned (see Figure 17).