Table Leadscrews

Lube Type.. Model SB1365 or ISO 68 Equivalent

Lube Amount | Thin Coat |

Lubrication Frequency | 40 hrs. of Operation |

To lubricate table leadscrews:

1.DISCONNECT MACHINE FROM POWER!

2.Using

3.Use a 4mm hex wrench to remove rubber way cover, then use mineral spirits and a brush to clean existing grease and debris off of

Leadscrew

Figure 38. Location of Y-axis leadscrew.

4.Apply thin coat of ISO 68 machine oil to exposed leadscrew threads, then move table through its full range of cross motion sev- eral times to disperse oil along full length of leadscrew.

5.Using X-axis handwheel, move table as far to one side as possible.

6.From beneath table, use mineral spirits and a brush to clean as much of existing grease and debris as possible off of

Figure 39. Location of X-axis leadscrew.

Headstock Gears

Lube Type..Model T23964 or NLGI#2 Equivalent

Lube Amount | Thin Coat |

Lubrication Frequency | 90 hrs. of Operation |

To lubricate headstock gears:

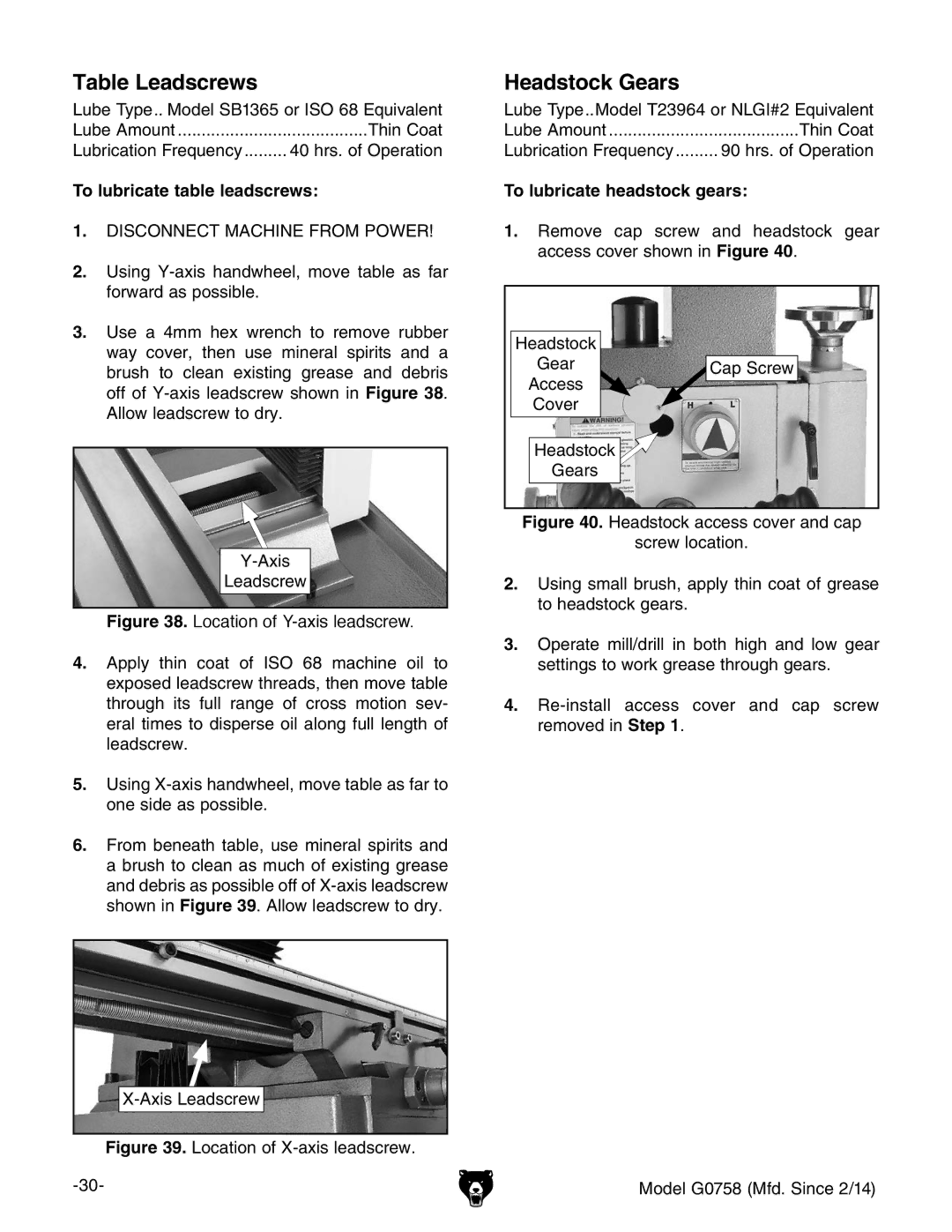

1.Remove cap screw and headstock gear access cover shown in Figure 40.

Headstock |

|

Gear | Cap Screw |

Access |

|

Cover |

|

Headstock |

|

Gears |

|