Removing Tooling |

|

Tools Needed | Qty |

Spindle Pin | 1 |

Wrench 8mm | 1 |

Brass Hammer | 1 |

To remove tooling: |

|

1.DISCONNECT MACHINE FROM POWER!

2.Remove drawbar cap and secure spindle with spindle pin. Unthread drawbar from tool- ing one full rotation.

Note: Do not fully unthread tooling from drawbar or the drawbar and tool threads could be damaged in the next step.

3.Tap top of drawbar with brass hammer to unseat taper.

4.Hold onto tooling with one hand and fully unthread drawbar.

Spindle Speed

Using the correct spindle speed is important for safe and satisfactory results, as well as maximiz- ing tool life.

To set the spindle speed for operation, you will need to: 1) Determine the best spindle speed for the cutting/drilling task, and 2) adjust the gear box knob and

Determining Spindle Speed

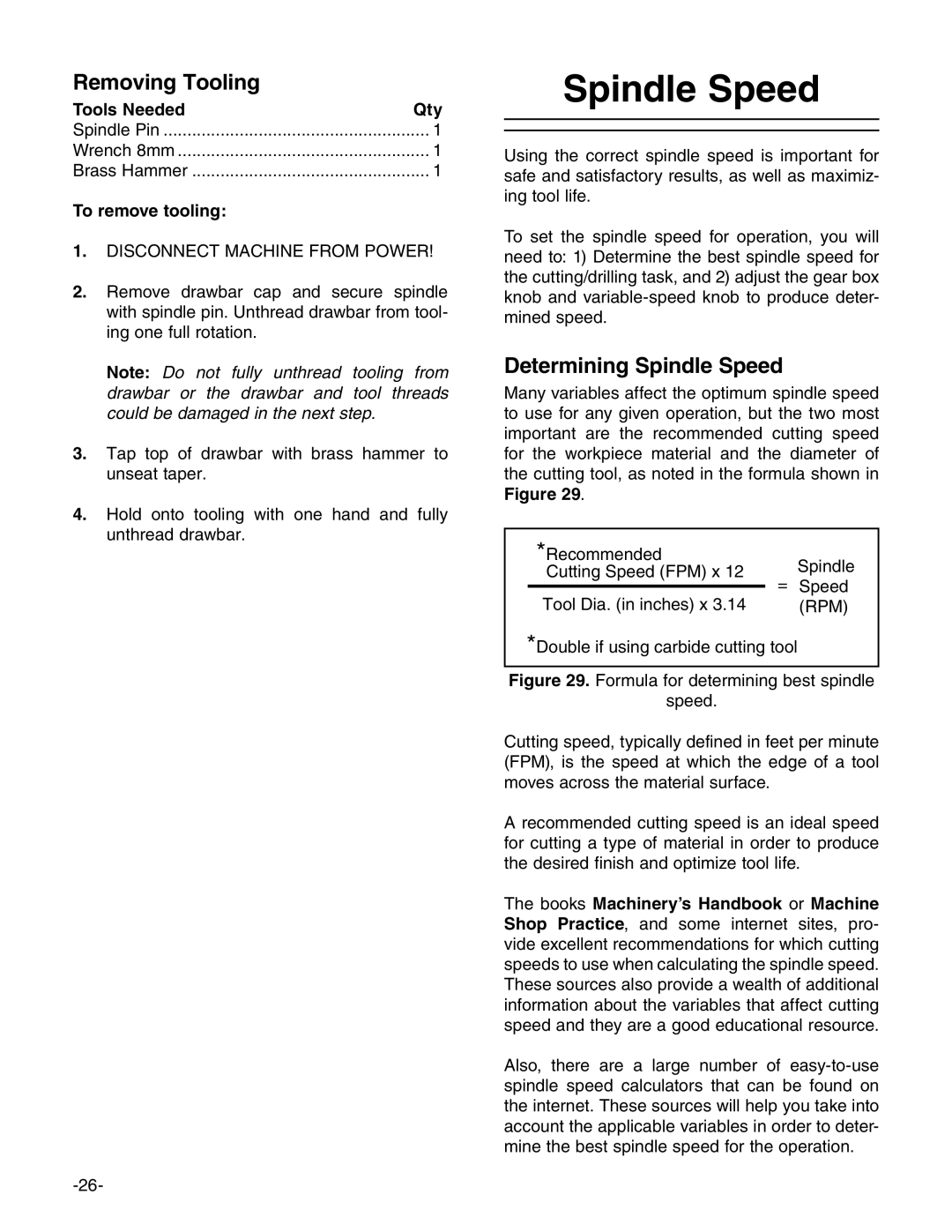

Many variables affect the optimum spindle speed to use for any given operation, but the two most important are the recommended cutting speed for the workpiece material and the diameter of the cutting tool, as noted in the formula shown in Figure 29.

*Recommended |

| Spindle | |

Cutting Speed (FPM) x 12 | = | ||

Speed | |||

Tool Dia. (in inches) x 3.14 | |||

| (RPM) |

*Double if using carbide cutting tool