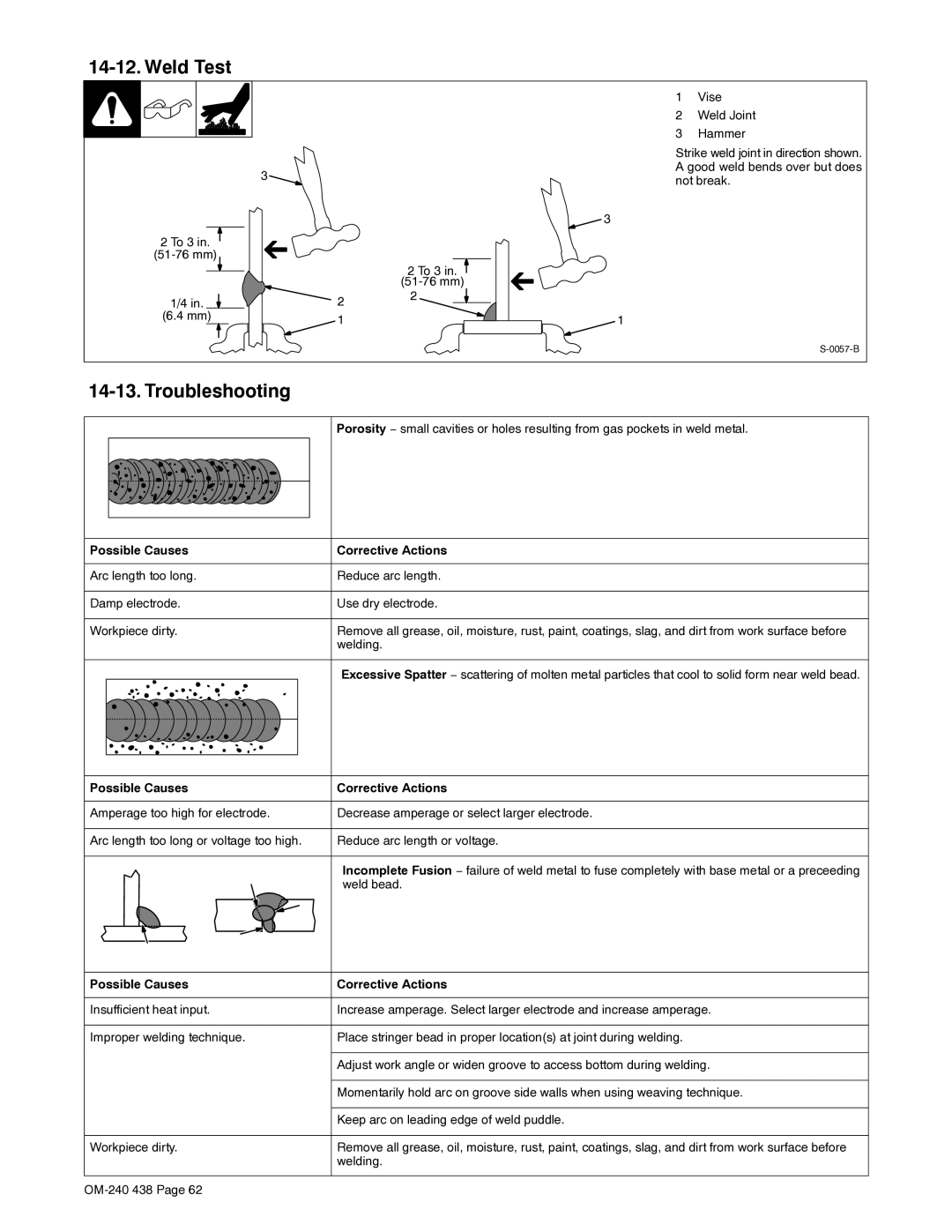

14-12. Weld Test

2 To 3 in.

(51-76 mm)

1/4 in.  (6.4 mm)

(6.4 mm)

3 |

|

| 3 |

| 2 To 3 in. |

| |

2 | 2 |

| |

1 | 1 |

1Vise

2Weld Joint

3Hammer

Strike weld joint in direction shown. A good weld bends over but does not break.

14-13. Troubleshooting

Porosity − small cavities or holes resulting from gas pockets in weld metal.

Possible Causes |

| Corrective Actions |

|

|

|

Arc length too long. |

| Reduce arc length. |

|

|

|

Damp electrode. |

| Use dry electrode. |

|

|

|

Workpiece dirty. |

| Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before |

|

| welding. |

|

|

|

|

| Excessive Spatter − scattering of molten metal particles that cool to solid form near weld bead. |

|

|

|

Possible Causes | Corrective Actions |

|

|

Amperage too high for electrode. | Decrease amperage or select larger electrode. |

|

|

Arc length too long or voltage too high. | Reduce arc length or voltage. |

|

|

| Incomplete Fusion − failure of weld metal to fuse completely with base metal or a preceeding |

| weld bead. |

Possible Causes | Corrective Actions |

|

|

Insufficient heat input. | Increase amperage. Select larger electrode and increase amperage. |

|

|

Improper welding technique. | Place stringer bead in proper location(s) at joint during welding. |

|

|

| Adjust work angle or widen groove to access bottom during welding. |

|

|

| Momentarily hold arc on groove side walls when using weaving technique. |

|

|

| Keep arc on leading edge of weld puddle. |

|

|

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before |

| welding. |

|

|

|